Fitting sales forecasts within a six- to eight-week window can indicate a significant edge in getting products to market when customers tend to plan theirs months in advance. That level of sales turnover is both a reality and a point of pride at Griffin Industries, a Green Bay, Wisconsin-based provider of foundry tooling, machined parts and engineering services. Among other factors, the company’s speed depends on a substantial investment in metrology. It credits one tool in particular, a Romer Absolute Arm portable CMM with integrated laser scanning from Hexagon Metrology (North Kingstown, Rhode Island), for reducing inspection times by an estimated 25 percent.

Griffin Industries got its start in 1983 as a pattern shop specializing in prototype, thin-walled aluminum die castings and hydraulic valve bodies. Since then, its services have expanded to include not only prototype and production tooling for castings in a range of materials, but also finished parts and assemblies as well as problem-solving services for OEMs with thorny engineering issues or a need to expedite parts. Since 2003, the company reports that sales have quadrupled, and its facility has expanded from 7,000 to 28,000 total square feet.

Having been ISO-certified since 2003, Griffin is no stranger to quality control. For measurements requiring the highest precision, the company relies on three Brown and Sharpe bridge-type CMMs from Hexagon: A Gage 2000, a ONE and a Global Performance. All are installed in a temperature-controlled quality lab designed to handle virtually any measurement application the company might encounter (the fact that the Global Performance’s size mirrors that of the company’s largest machine tool is no accident). A typical day might involve three to four setups on each of the company’s 14 total CNC machines to keep as many as 50 prototypes moving through various stages of production.

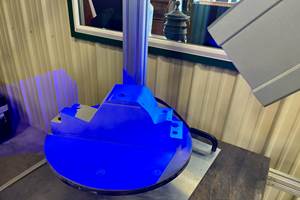

This flow of jobs is sufficient to keep the CMMs busy. Whenever possible, however, Griffin uses the portable Romer arm to keep parts out of the quality lab altogether. The ability to take measurements within CNC machine workzones eliminates the delays and machine idle time associated with removing parts from fixtures and transporting them to the quality lab for critical measurements. Rather, quality technicians can take measurements at the machine without disrupting the setup and let operators proceed afterward. This capability is used largely for cast work as well as machined patterns and other tooling used in the casting process.

The articulating arm isn’t the company’s first portable measurement system. Installed about a year ago, it replaced an earlier-model Romer arm that provided many of the same advantages. However, the Absolute Arm features an integrated laser scanner that provides even greater time savings. Previously, operators could check only one point at a time in relation to the CAD model. Now, they can gather millions of points in minutes to verify features and obtain a dimensional overview of a given part. The company credits the arm’s absolute encoders for additional time savings. By determining the arm’s position the moment it’s switched on, the encoders eliminate the need for time-consuming homing procedures.

“We have found uses for scanning throughout the tooling, casting and machining process,” says Jonathan Krouth, company president. One of the most common applications is in the tooling phase, when operators scan each component to verify dimensional integrity with the original CAD model. This also provides a baseline for evaluating tooling wear in the future. He adds that even if a machined part’s tolerances dictate measurement on one of the shop’s CMMs, the arm’s scanning capability can be used to verify that all machined features are present.

Another common application is checking similar parts produced on different machines. Consider the case of a design change on the inside cavity of an existing pattern. While the cavity and the corresponding insert are milled on different machines, the articulating arm can verify that all features on the insert are oriented correctly in relation to the corresponding features on the cavity.

The company also uses the arm to ensure correct allowances for shrinkage in foundry patterns. After the casting process, the recently solidified metal often shrinks as it cools, and patterns must be produced slightly oversized to compensate. Upon receiving such a pattern, a foundry typically creates a sample casting to return to Griffin for verification before proceeding with the remainder of the parts. Griffin performs the necessary machining and checks the parts after each operation with either the arm or a CMM, depending on tolerances. Rather than verifying sample castings in-house, Griffin has been known to bring the arm on-site to foundries and approve them on the spot, thereby saving time and adding a personal touch to customer service.

For in-house inspection of sample castings, the company deems the arm’s laser-scanning capability essential. Previously, these inspections required manually creating sand molds from patterns and comparing various points to the corresponding CAD model. To verify that the cope and drag halves of each mold lined up properly, the company would set up tooling points on one half and use those points to perform a three-point alignment on the other. Now, it simply scans the two halves and “knits” them together in a virtual CAD environment. This saves time and material by reducing the need to make sand molds.

The company also uses the arm for more than just formal measurements. For example, some parts’ material properties cause them to change form when released from a machining fixture. In that case, checking flatness or other such attributes while the part is still subject to tension from workholding devices is essentially akin to inspecting it in the assembled state, the company says. Performing this same type of simulation on a bridge-type CMM would require not only moving the part, but also the use of custom fixturing. In contrast, an operator using the articulating arm can drag the probe across the part surface and generate a real-time readout of any variation.

As a company that claims speed as a crowning achievement, Griffin takes full advantage of portable inspection to keep machined patterns and other parts out of the quality lab. With integrated laser-scanning capability, the shop’s latest model Romer arm goes even further in alleviating inspection bottlenecks to get parts out the door faster.

.png;maxWidth=300;quality=90)