Presetting Process Cuts Scrap, Rework

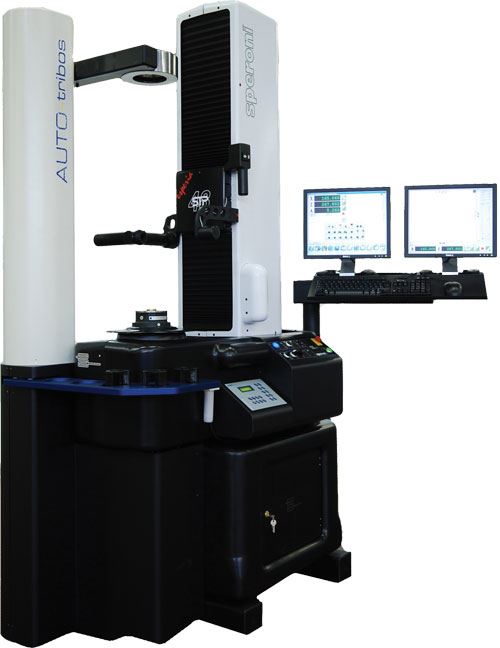

Aerospace manufacturer Fokker Aerospace Group relies on Speroni’s STP46 tool measuring and presetting machine to ensure that step drills used to cut and chamfer holes on aircraft flap skins are within tolerance and set to the proper length. This machine and custom procedures developed by Speroni enables the aerospace manufacturer to avoid cost and downtime resulting from reworking or scrapping these large parts.

Rework or scrap can take a toll on the profitability of any job, but getting it right the first time is especially important for large parts that require a large number of operations. Fokker Aerospace Group, a manufacturer of commercial and military aircraft components in the Netherlands, recently optimized a critical drilling and chamfering process to avoid wasting time and money on one such series of parts. Key to this optimization was a measuring and presetting machine from Italian manufacturer Speroni that ensures the company’s tooling is properly set to machine within tolerance.

Fokker Aerospace Group has more than 90 years of experience in producing high-quality components for military and civil aviation applications. Among the many parts produced at its production site in Papendrecht are flaps for both private and commercial aircraft from manufacturers including Boeing, Dassault and Gulfstream. Each flap skin requires drilling nearly two thousand holes to accommodate fasteners that mate the skin to the aircraft’s frame. The most challenging part of this operation—besides drilling each hole in the correct position—is ensuring that the fasteners are flush with the flap surface. This is critical because the flap needs an even surface to pass final inspection.

The decisive factor in keeping the fasteners properly positioned is the chamfering of each hole. Too small, and the fasteners would protrude past the top of the flap skin. The chamfers could be reworked, but doing so for thousands of holes would require a significant time investment. Cutting the chamfers too large, which would cause the fasteners to sit beneath the surface, would be an even worse scenario. In that case, no amount of rework could remedy the situation, and the expensive part would be lost.

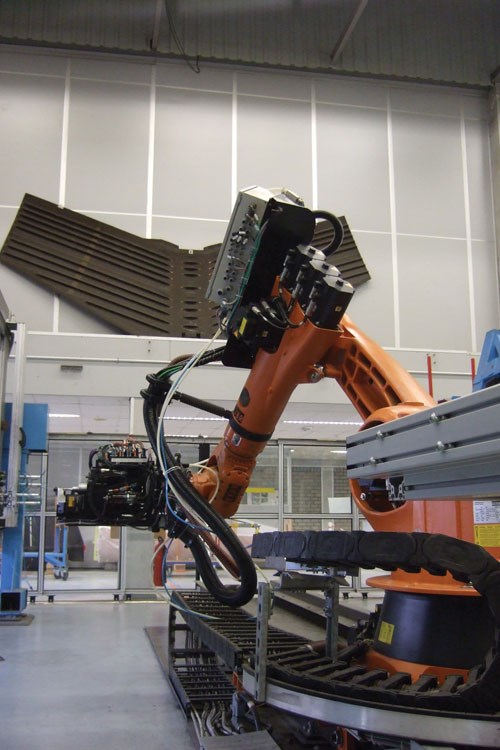

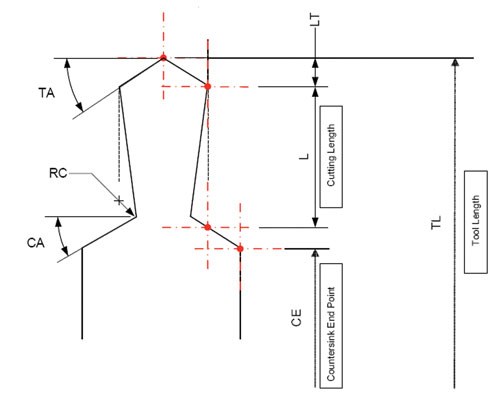

Considering the time and effort that goes into each of these valuable parts, the company sought to improve the process. The first step was to automate by installing a robot that can complete drilling and chamfering operations in slightly less than three hours per flap. However, the company still needed a way to guarantee that the step drills used for this process were in tolerance and set to the proper length within their Schunk Tribos HSK 32 toolholders. Other than tool length (TL), the most decisive parameters to be measured on the drill are the cutting length (L) and the countersink end point (CE). This is a challenging task because both of the latter points are located on the drill’s 40-degree chamfer angle (see the diagram on the right side of the page).

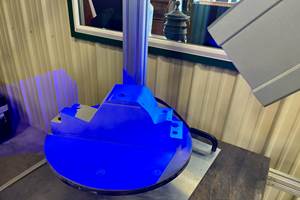

Feeding the robot’s controller with the proper data to keep the drilling process within tolerance would require a system that could not only preset the tooling within the Tribos toolholder, but also execute a complete measuring cycle afterwards. After scouring the market for a solution, the company chose Speroni’s Esperia STP46 tool presetting and measuring machine (Speroni equipment is available in the United States from Hoffman Estates, Illinois-based BIG Kaiser Precision Tooling). "This was a long project for our company, but we finally found the right supplier in Speroni, which not only builds its presetting and measuring machines in-house in Italy, but also is capable of customizing the system according to our specific needs," says Roy Helmos, junior process specialist at Fokker Aerospace Group.

An example of this customization is the integrated tool identification option for data output after the measuring cycle. To help avoid scrap and rework, Speroni developed special warnings that notify operators when any parameter is out of tolerance, preventing them from writing faulty data to the chip. "We had some special wishes in this regard, and the software development department at Speroni reacted promptly to our demands," Mr. Helmos notes.

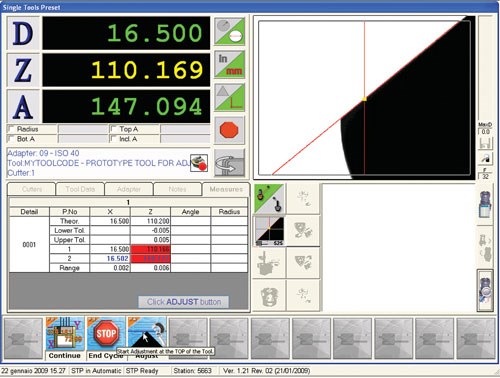

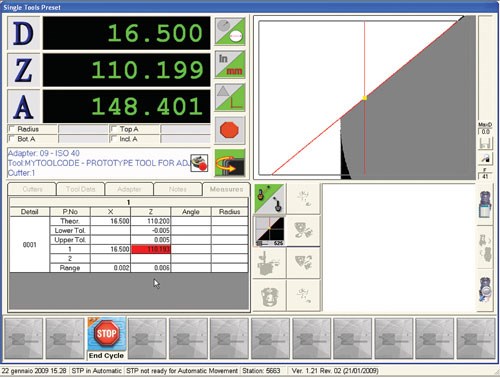

Another special task Speroni performed for Fokker Aerospace Group was the development of a three-step procedure that enables operators to easily set the tool at a given diameter at the 40-degree chamfer to a specific length. (Photos depicting each step are located at the right side of the page). First, the machine detects the highest point of both flutes and measures the length at a given diameter on the chamfer of the drill.

Then, the measuring machine automatically detects the top of the drill to actually set the tool to the desired length. The length axis switches to a differential value that shows the operator exactly how to adjust the tool to set it within tolerance. Using the top of the drill makes it much easier to set the tool’s length, the company says.

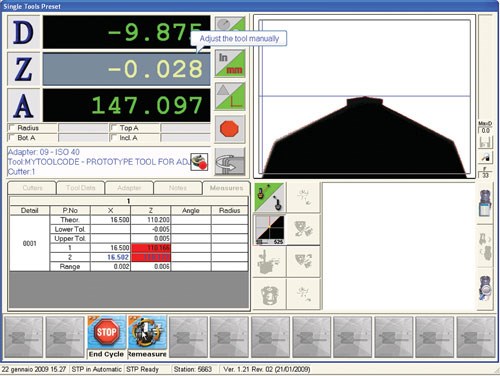

Finally, the machine positions its camera back to the chamfer, re-measures the length at the given diameter and notifies the operator whether the length has been set within tolerance. The specific routines used to inspect these tool features are accessible to operators through a database of more than 150 icons.

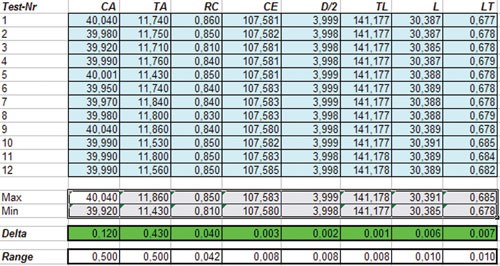

Fokker Aerospace Group has strict standards for the installation and acceptance of any machine. The measuring machine was pre-accepted at Speroni’s facility in Spessa, Italy before being shipped to Papendrecht and installed near the drilling robot. Once installed, the machine was checked and correctly aligned before undergoing an acceptance test. First, the tool had to be set to the correct length using the procedure described above. After that, the tool needed to be measured in several steps to establish 8 different parameters, including all of those seen on the diagram at the upper right of this page as well as the cutter’s diameter. Measurements had to be accurate within a given range, which was different depending on the specific parameter but never any larger than ±0.005 mm.

However, these tight tolerances weren’t the only demands placed on the machine. To evaluate repeatability, the tools were unclamped from the spindle and re-clamped before every cycle, Mr. Helmos says. He concludes that the results of the setup and measuring procedure as well as acceptance test conducted on the shop floor proved that the machine’s precision and repeatability were more than enough to meet the company’s requirements.

According to the manufacturer, the STP46’s performance can be attributed to its aged and balanced cast iron base combined with high-precision, linear steel guideways. These features keep the machine stable and geometrically aligned, even when installed next to production machines on the shop floor. "Speroni showed that it is not only very flexible when it comes to customizing the software according to our needs, but also—and this is most important to us—that the machine is capable of measuring precisely, within microns."

Related Content

Understanding Errors In Hand-Held Measuring Instruments

Different instruments (and different operators) are prone to different errors.

Read More4 Ways to Establish Machine Accuracy

Understanding all the things that contribute to a machine’s full potential accuracy will inform what to prioritize when fine-tuning the machine.

Read MoreA Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read MoreHow to Choose the Correct Measuring Tool for Any Application

There are many options to choose from when deciding on a dimensional measurement tool. Consider these application-based factors when selecting a measurement solution.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More