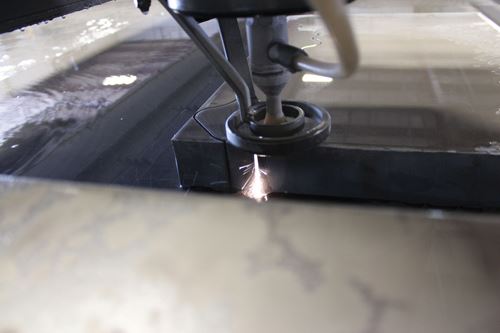

Affectionately dubbed “Frankenstein,” Midwest Precision’s oldest waterjet is still capable of doing some impressive work, says Brian Miller, company president. Cobbled together over the course of nearly two decades with various parts from a number of suppliers, the machine could be seen to represent both the legacy of this shop’s particular experience with waterjet technology and how far that technology has come.

It was late 2010 when Frankenstein finally reached the peak of its potential. Although the machine would continue to be useful, keeping pace with ever-increasing requirements for cutting speed and accuracy would require entirely new equipment. The solution was two Mitsubishi waterjet systems from MC Machinery Systems (Wood Dale, Illinois) fitted with Streamline Pro 125 hydraulic intensifier pumps from KMT Waterjet Systems (Baxter Springs, Kansas). These systems have expanded the range of work the shop can efficiently process via waterjet, which is often used as a cost-effective alternative to laser processing.

Playing Leapfrog

Expanding its range of work is one of the first benefits Midwest Precision realized from implementing waterjet cutting in the first place. Based in a 100,000-square-foot facility in Tulsa, Oklahoma, the 55-employee shop has focused primarily on sheet metal fabricating operations such as welding, punching, laser cutting, and brake and roll forming since its founding in 1973. Adopting waterjet technology in 1992 didn’t change that, but it did enable the shop to cut materials it never would have considered before, including glass, phenolics, plastic, stone and more. “Waterjet is by far the most flexible of any of our processes,” Mr. Miller says. “There are some important customers that we simply wouldn’t have without it.”

As waterjet technology evolved, so did customer expectations. Having been refurbished with new controls, drives and other components over the years, Frankenstein is a testament to Midwest Precision’s willingness to make the investments required to meet those expectations. One of the most significant upgrades for that aging platform came a few years ago, when, reflecting a wider industry evolution toward higher pump pressure and horsepower, the shop replaced its 50-hp, 50,000-psi pump with a 60-hp, 90,000-psi model from KMT. “The new pump alone immediately increased the feed rate and capacity of that piece of equipment,” Mr. Miller says.

Before long, however, Midwest Precision found itself facing the same problem that prompted the pump upgrade. The company was slowly and steadily losing market share due to outdated technology. This time, however, Mr. Miller realized that putting money into existing equipment would no longer be sufficient to match competitors’ cutting speed and accuracy.

The solution would have to be twofold. A more powerful pump could improve cutting speed, just as it had in the past. KMT would again be an obvious fit, given the shop’s long relationship with that supplier and the fact that one of its newer pump models, the Streamline Pro 125, was rated at 125 hp and 90,000 psi. However, a pump that powerful would require a more robust platform than any waterjet the shop used at that time. Also, a larger pump alone wouldn’t help with improving precision.

A Change in Motion

In late 2010, the shop decided on two Mitsubishi waterjets: the DX510 and the larger DX612. Both shipped with the KMT Streamline Pro 125 pump the shop had been eying, while other features ensured the new waterjets could meet the required level of precision.

Accuracy improvements can be attributed in large part to the machines’ motion systems, Mr. Miller says. Both employ linear motor guides driven by dual AC servomotors and high-pitch, 32-mm, double-anchored ballscrews. In contrast, the shop’s previous equipment used belts and drives for axis motion. Those systems were prone to slippage, and the belts tended to lose elasticity over time.

He adds that Mitsubishi’s Intelligent Taper Control technology also contributes to accuracy. This system automatically tilts the cutting head to compensate for the natural tendency of a waterjet stream to “flare out” and become wider as it exits the nozzle. According to the developer, this provides improved part wall straightness of ±0.001 inch per 1/2 inch of workpiece thickness.

With the new machines, the shop regularly meets ±0.001 inch straightness in holes cut to ±0.002 inch in 1/4-inch-thick plate, Mr. Miller says. The shop’s older equipment could achieve only ±0.02-inch hole tolerances—still often with concentricity issues— and ±0.03-inch straightness.

Pumping up the Speed

At 90,000 psi, the KMT Streamline Pro 125 generates the same amount of pressure as Frankenstein’s pump. However, with 125 hp—more than double the 60 hp of the older model—it can be paired with a larger nozzle (0.016 inch versus 0.011 inch) without reducing the stream’s velocity. Mr. Miller credits this difference for the new machines’ ability to not only cut faster, but also to process thicker material. “It all comes down to the fact that with higher horsepower, we can push a higher volume of water,” he says.

All things being equal, higher pressure generally increases cutting speed, explains Neil Anderson, vice president–engineering at KMT. This accounts for the gains realized when the shop replaced Frankenstein’s 50,000-psi pump with the 60,000-psi pump a few years before. However, even at the same psi, pushing a higher volume of water through the cutting nozzle introduces more abrasive to the workpiece material. Because the abrasive, not the water, is responsible for eroding the material, the shop was able to achieve similar cutting speed advantages with its latest investment. Additionally, the larger nozzle orifices emit wider streams that penetrate thick material more effectively.

At Midwest Precision, increased pump horsepower has enabled running the Mitsubishi machines at feed rates that are an average of 300 percent faster than those of the shop’s previous equipment, Mr. Miller says. In terms of material thickness, the waterjets set a new shop record on a job that required cutting through 5 1/4-inch-thick PH stainless steel. Previously, the shop would have been able to cut only about 3 inches, and surface finish would likely have been questionable at best, he says.

Although pushing 90,000 psi can strain any system, newer waterjets typically feature components that are designed to better withstand higher pressures than those of older systems. For instance, the cutting heads on Midwest Precision’s new waterjets feature diamond orifices. Other features, such as flexible whip tubing that transmits water directly to the cutting head without expensive couplers and high-pressure swivels, further reduce costs. The shop can also opt to run at 60,000 psi when faster cutting wouldn’t offset the cost of more wear and tear.

Mr. Miller also notes that optional closed-loop filtration systems from Ebbco (New Baltimore, Michigan) save money by reclaiming and reusing water. “Before, one of our biggest expenses was keeping the pump hydraulics cool and replacing the water in the tank,” he says. “We like this system so much that we’re planning to purchase another to install on Frankenstein.”

A Cost-Effective Alternative

The new equipment provides two primary advantages for Midwest Precision, Mr. Miller says. First, waterjet often provides a cost-effective alternative to laser cutting for parts that could fit either process, and the ability to cut faster and more accurately enhances this role. Although laser is faster, the shop’s waterjets are less expensive to operate and maintain, he explains. Waterjet also tends to perform more predictably on thicker parts in “bright” metals, such as aluminum and stainless. Additionally, work hardening due to heat is not a concern with waterjet. This is especially advantageous for aerospace and defense contracts, some of which call specifically for waterjet cutting.

Jobs like that exemplify the other main advantage of more advanced waterjet capability: the capacity to take on work the shop otherwise couldn’t touch. Another example is work subcontracted from machine shops that turn to Midwest Precision for waterjet cutting of near-net-shape blanks. This accounts for many of the shop’s newer contracts and typically involves workpieces that are unsuitable for effective laser cutting. “Waterjet is like a whole different business for us—when you get into 5-inch-thick stainless, that’s out of the realm of anything else we do,” Mr. Miller says. “We’re running parts that we would’ve never been able to run before faster and more accurately.”

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)