It is not often that I walk into a machine shop to find an on-site vegetable garden and gym, complete with weights and stationary bikes. “We like to show our employees that we’re grateful to them,” says President and CEO of AccuRounds Michael Tamasi. “If keeping a gym here means our people have an easier time staying healthy and active — that they can cut out the time and cost of a gym membership — then that’s worth it to us.”

These seemingly extravagant perks are perhaps the least extraordinary things about AccuRounds’ human resources strategy, which has earned the company a place in this year’s Top Shops Honors Program. This company's story proves that treating people fairly and valuing their contributions isn't just the right thing to do, but also a direct path toward greater profitability.

A Family Business

AccuRounds’ 45,000-square-foot machine shop offers milling, turning, grinding and Swiss-type turning, primarily for the medical and semiconductor markets.

In 1958, an Italian immigrant named Len Tamasi bought a centerless grinder and went to work. In 1976, Tamasi bought a shop that specialized in Swiss-type turning and renamed it AccuRounds. Over the ensuing decades, the shop branched out into CNC turning and milling, as well as CNC and conventional grinding. Today, the company is owned by his children, Michael Tamasi and Nancy Hunter, and operated by 73 skilled employees. Amid the pandemic’s fluctuating demand and supply-chain hiccups, the company has had two of its best years on record.

This part – used in the manufacture of vaccines – has tight internal and external tolerances achieved through turning and grinding that Tamasi claims the company’s competitors could not manufacture it.

Here we see some of AccuRounds’ employees working on Swiss-type lathes. Swiss-type machining makes up a large portion of the company’s overall business.

In part, this success is due to the end markets it serves –among other end markets, AccuRounds manufactures parts for the semiconductor and medical industries, including parts for vaccine centrifuges. Producing parts for such in-demand products as vaccines and semiconductors obviously carries a competitive advantage, and yet, for Tamasi, the company's edge still comes down to people. “We’re the only shop in the world who’s been able to make this part successfully,” Tamasi says, holding up a cylindrical part used in manufacturing semiconductors. “And we can only make it because the team member who coordinates our grinding value stream can meet the specs thanks to his years of experience.” This response is typical of Tamasi, who constantly directs attention toward the accomplishments of his employees.

Much of AccuRounds’ business revolves around the production of small, round parts with extremely tight tolerances.

On his wall is a plaque with the company’s mission statement on it, called the Path to Perfection. The principles listed at the top of the plaque are, “People, Process, Passion,” and the order is deliberate. “If you don’t care about your people, I don’t know why you’re in business,” he says. “Not only are you letting down your employees, but you’re going to get inferior products and hurt your business. If you start right, everything follows.”

Many businesses will tell you that they care about employees. AccuRounds proves it.

People, Process, Passion

Part of the GET IT set of values is Gratitude, which the company shows in numerous ways from compensation to recognizing efforts. In the company lunchroom, a plaque names workers who have been elected by their peers to be recognized for excellence.

AccuRounds’ mission statement further breaks down into five core values: Gratitude, Excellence, Team First, Initiative, and Trust – which forms the initialism GET IT. “The core values actually came before the mottos,” Tamasi says.

Consider gratitude. When he shows off the wall of awards the company has received, Tamasi talks about the efforts of his workers. The TV monitors in the main manufacturing rooms announce anniversaries, birthdays and guests. On employee birthdays and anniversaries, he mails them cards so their family can see that they are valued and hands them a gift in person. By emphasizing the need to appreciate coworkers and employees, he creates an environment in which people feel valued and ideas can spread. And yet, even in this case, he is quick to credit someone else. “I credit our head of HR Diane Ferrera with a lot of these initiatives,” Tamasi says. “She does a lot of the leg work to make sure that the way we treat our employees falls in line with our core values.”

These are not vague commitments for AccuRounds.

This jig was developed by an AccuRounds college intern who 3D printed it to deposit these disc-shaped parts on the conveyor belt face-up, preventing the finished side from getting scratched. The “Quick-and-Easy Kaizen” system encourages such efforts and ensures they are recognized.

One clever example of this focus on core values is the system the company calls Quick-and-Easy Kaizen, referring to the Japanese continuous improvement philosophy. When an employee develops a solution, they fill out a form on the computer and include pictures of the solution. The company publishes these in booklets – divided by year – that hang on the wall for everyone to access. This encourages team members to take the initiative to develop solutions and share them with the rest of the shop, and it enables the shop to credit employees for their creativity and problem solving.

“My most important job is making sure people understand and live up to these values.”

This simple practice demonstrates every part of the GET IT philosophy. “When you improve efficiency, you improve work life, so when someone solves a problem we publicize that to the rest of the shop,” Tamasi explains. “This is pursuing excellence, showing gratitude for the people coming up with the ideas, and putting team first by making sure everyone knows about this innovation.”

Furthermore, this dedication to core values is helpful when it comes to customer relationships. “We rely on long-standing relationships,” Tamasi says. “Customers recognize that we’re committed to excellence, but they also recognize that we value them and will work with them to overcome challenges.”

Continuous Learning

Resources for employees to learn and grow are considered critical to continuous improvement. The company contracts with LinkedIn Learning Solutions to provide online coursework through a program the it calls AccuRounds Lifelong Learning University (ALLU). The training program offers both fundamental skills and advanced techniques for working with most of the manufacturing equipment at the facility. Employees are free to tackle training at their own pace and to their own interests. “Some people, they want to generalize so they can be helpful with a lot of different machines,” Tamasi says. “Others specialize so they can be experts in a few areas.”

This board uses a grid with color-coded dots to track employee progress with each machine in the company’s online learning platform.

A whiteboard tracks the training of all shopfloor personnel. For each machine on a grid, different colors indicate beginner, intermediate and advanced training either as an operator or in setup. “We keep track of it in a public space like this so that everyone knows who might be able to provide input with which machine,” Tamasi says. “It also gives people a place to celebrate each other’s accomplishments.”

However, ALLU is not only for training on machines. “The program we use has classes for all sorts of things,” Tamasi says. “We encourage people to take leadership and communication classes — anything that builds their soft skills — because that makes work run smoother.”

“If you start out right, everything follows.”

There are also classes unrelated to work altogether. “If someone wants to take a writing class through ALLU, that’s great,” Tamasi says. “We want our people to feel like we give them a good work-life balance, and if they take classes purely for self-enrichment, then that’s a good use of resources.”

Further, Tamasi said that the effort to police what learning modules employees have access to simply is not worth the time. “If someone isn’t putting effort into work, it’s not a secret to us. If someone is putting a lot of effort into improving their output and improving their machine knowledge, then whatever else they do with those resources doesn’t bother me. Why should it?”

So Many Amenities

Having a gym on site allows the company’s employees to work out without needing a gym membership or having to deal with a commute. Tamasi says taking those taxes on his people’s time and money is worth it, especially considering the health benefits.

AccuRounds’ HR strategies are not limited to training and celebrating technical accomplishments. The company also provides better compensation than most machine shops, as well as excellent healthcare. Additionally, there are bonuses tied to production that are paid out every six months. “You have to compete with the market, and New England is a high-cost market,” Tamasi says.

The company's approach seems to be working, as the average employee spends around 11 years with the company. Tamasi says the most important factor in retaining employees so well is in behaving in a way that attracts the kind of employee he wants at AccuRounds. “We want people who value sustainability, so we installed solar panels and recycle our oils. We want our people to feel healthy and have energy for work, so we installed a gym and planted a vegetable garden. We want people who will take initiative at their positions, so we celebrate their accomplishments.”

“We don’t have enough people, but we have the right people.”

In hiring, Tamasi says he looks for people who will embrace the company’s culture of collaboration and continuous improvement. “We don’t want siloed workstations or people who are only interested in their own numbers,” Tamasi says. He also emphasizes that the company does not budge when it comes to this practice. “Our values are what make us competitive and strong. My most important job is making sure people understand and live up to these values.” If someone has the skills to work with precision machining centers, but does not embrace their core values? “We don’t hire them,” he says. “I don’t care if they’re the best machinist in the world if they aren’t going to do right by the people around them. An uncooperative attitude poisons a workplace.”

This hiring practice has led to the company hiring many employees without strong backgrounds in manufacturing, but who were willing to work hard and learn. This has created a diverse workforce, including many women and people of color in an industry that is overwhelmingly white and male. “We’re very happy to have embraced diversity because not only does it feel like the right thing to do, but because having many perspectives adds value,” Tamasi says.

Of course, the company struggles to find employees just like any other. Nonetheless, the commitment to company culture remains unwavering, Tamasi says. “We don’t have enough people, but we have the right people.”

Investing in Technology is Investing in People

A machine shop does not run on people alone, and AccuRounds is no stranger to automation. However, “Robots will never replace people,” Tamasi says. “Not at AccuRounds.” Rather than replacing people, he views automation systems and other technology as a means to improve capacity by enhancing their work.

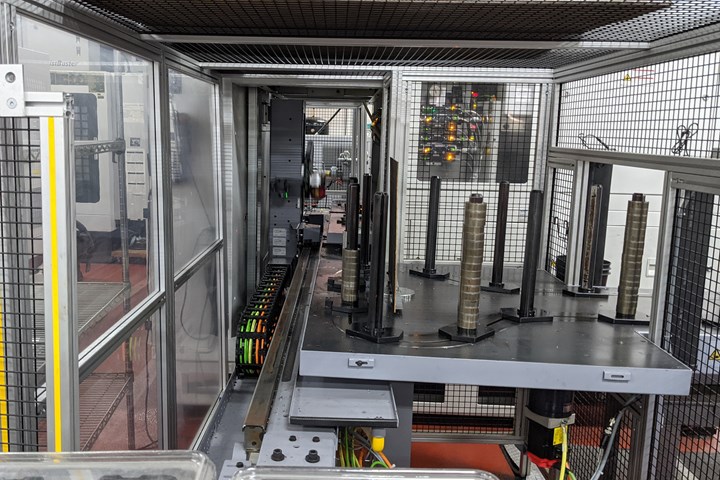

A robot arm removes the ring-shaped Inconel discs from the long poles and places them in the machining envelope of an EMAG VL2 vertical turning machine, then places the finished part on a separate pole.

“Robots will never replace people. Not at AccuRounds.”

Michael Tamasi stands next to AccuRounds’ tool vending system from MSC. The system enables the shop to keep track of cutting tool inventory, including who has which tools and what condition they are in. This makes keeping cutting tools in stock simple.

As examples, he cites two investments that resulted in pushback from some employees. The first was an MSC tool vending system that tracks stock and usage rates to reduce time spent looking for, ordering and waiting for tools.

The second was a MachineMetrics machine monitoring system that tracks uptime and downtime. “We just reminded the team that we were monitoring processes, not the people,” he says. “And we stuck to that. When we detect downtime, we don’t go after people.”

As with other aspects of the business, AccuRounds benefits from being clear, honest and forthright with employees when implementing these solutions. “I think AccuRounds is proof that you can achieve greater success by bringing the right people onboard and being decent to your employees.”

Related Content

YCM Alliance Hits IMTS

YCM Technology has joined with other like-minded machine tool manufacturers to take a solutions-based approach to manufacturing.

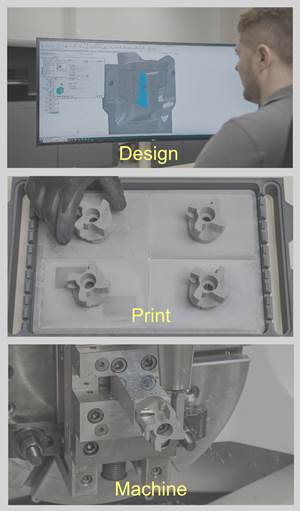

Read MoreSolidCAM Wants to Help Machine Shops Get into Additive Manufacturing

SolidCAM's partnership with Desktop Metal is aimed at making additive manufacturing more accessible to job shops and other manufacturers.

Read MoreBest Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

Read MoreView From My Shop, Episode 2: 3D Printing and Postprocessing With Tangible Solutions

Collaboration between Tangible Solutions’ additive and machining departments simplifies their work. Learn more in this episode of The View From My Shop.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)