Reducing Cycle Time With Tool Selection/Management Program

Most products at BuTech are turned from Type 316 stainless steel bar stock with hardnesses of 28 to 32 HRC. The cold-worked stock provides a higher hardness than typical for this stainless steel type.

BuTech Pressure Systems (Erie, Pennsylvania) manufactures high pressure valves by turning and milling all the components of the valve, then assembling them. Customers for these new generation ball-valves, for oil and hydraulic systems, are primarily in the petroleum and aerospace industries. Most products at BuTech are turned from Type 316 stainless steel bar stock with hardnesses of 28 to 32 HRC. The cold-worked stock provides a higher hardness than typical for this stainless steel type. Hardness ensures the tensile strength required by the high pressure valves. BuTech also turns and mills ballvalve components from high nickel content stainless steel and high temperature alloys.

When jobs came into BuTech, turning operators would request a particular tool from the toolroom. According to Ron Renner, manager of the toolroom and of purchasing, these requests were based on memory and previous good or bad experiences. "Each operator had their own tool preferences. The cutting tools for a given part would vary by operator," Mr. Renner recalls. While the operators were focusing on doing the job right, their preferences weren't necessarily based on any concrete reasoning.

Mr. Renner saw the frustration operators experienced when setting up a job, installing the tool and setting cutting parameters. The nonstandardized method of identifying a tool and its correct cutting data resulted in what became known as the "cut-and-hope" method of job setup. According to Mr. Renner, "We weren't really sure how well the cutting data would perform with any tool. Too often, we saw inconsistent tool life or tool damage, which led to machine down time. We also scrapped a lot of workpieces because of these issues."

These frustrations with tooling selection could interfere with lead times. "We run a lot of small batches and don't have a lot of lead time," explains Mr. Renner. "We wanted to be able to troubleshoot our cutting problems without taking time to contact the tooling supplier."

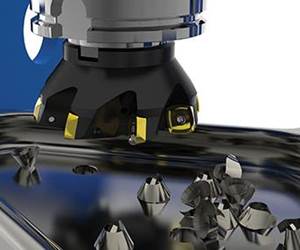

The company also wanted to increase turning productivity, so it was investigating methods to expedite identification of the right roughing and finishing tools. Tool selection also had to include cutting parameters that worked without fail. BuTech and Mr. Renner decided to try the Sandvik CoroKey Tool Selection Program from Sandvik Coromant (Fair Lawn, New Jersey). The program guides tool selection by conducting the search in stages according to readily available information.

The CoroKey program was introduced to Mr. Renner through his local distributor and a Sandvik representative, Enzo Leo. "Initially, the Sandvik representative gave us some tools and their recommended cutting data. We did what the program said to do. Every time, the cutting recommendations proved successful. Once we saw how well Sandvik tools and the cutting recommendations performed, we were eager to hear about CoroKey." In the first pass, inserts are sorted according to workpiece material, which determines the type of cutting insert family. Inserts for steel, cast steel and malleable iron are color coded blue and letter coded "P." Inserts for stainless steels are color coded yellow and letter coded "M." Inserts for cast iron are color coded red and letter coded "K."

The second pass considers the type of application and indicates the geometry of the insert. For either turning or milling, inserts are sorted according to light ("F"), general purpose ("M"), and heavy duty ("R") conditions.

The final selection pass allows consideration of the machining conditions and indicates the insert grade. For either turning or milling, inserts can be selected to handle "good," average" or "difficult" conditions.

Based on cutting objectives, such as versatility, productivity and security, operators can choose the best tool. For all inserts, recommended cutting data are printed directly on the insert box to assure optimum efficiency in use. These data are based on extensive laboratory tests and controlled field application of the inserts and are constantly updated.

Through CoroKey, operators have cut the amount of time needed to identify the right tool and cutting parameters for the job. No longer do operators have to "cut-and-hope" when starting a job. According to Mr. Renner, "The real advantage of CoroKey is not its impact on any particular product we manufacture. The real impact comes from the system allowing operators to choose and apply their tooling more effectively."

"Many tools can run correctly and run well," says Mr. Renner. "What is critical is that the cutting data selected for a certain tool is available, accurate and easy to read. Many tool suppliers make quality tooling, but if we don't run their tools correctly, they will fail."

"Getting operators to understand this point was a slow revolution for Mr. Renner. "I didn't have the power to tell the operators to use only the Sandvik inserts and the CoroKey system. It wouldn't have worked if I just handed them the insert and gave them some numbers."

To encourage use of CoroKey, the Sandvik representative and Mr. Renner worked beside the operators while they ran the tools at the suggested feeds and speeds. This proved to be quite effective in promoting acceptance of systematic tool selection. "They saw that the cutting recommendations worked well and also that the increased cutting speeds did not mean additional headaches," says Mr. Renner.

The performance of the tools at the recommended feeds and speeds provided operators with faster cutting times. The overall result has been shorter cycle times and higher job throughput. "It has been common to reduce cycle times by 30 percent," says Mr. Renner, "and not uncommon to reduce them by 50 percent."

The new tool selection program has also reduced the tool inventory. "We have minimized the number of tools necessary to do our work, yet we have all the tools we need for every application," explains Mr. Renner.

CoroKey has allowed BuTech to make the most of its resources. "Faster speeds and feeds mean higher throughput and greater operator productivity," Mr. Renner claims. Since implementing CoroKey, he sees less frustration on the floor since tool life is now predictable, and cutting parameters are close to optimum for each tool. "Operators know they can put a tool in, insert the part, "push the button and have confidence that the tool will work well."

Related Content

All-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

Read MoreA New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read More10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

Read MoreHow to Turn Machine Shop Downtime Into Process Expertise

To take advantage of a lull in business, JR Machine devised a week-long cutting tool event that elevated the shop’s capabilities with aerospace alloys.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)