Rethinking MRO Challenges with Desktop Metal's Studio System

The second-generation Studio System simplifies the design process and eliminates common safety hazards of metal AM, increasing accessibility for manufacturers.

Desktop Metal’s Studio System 2 eliminates loose powder and does not rely on powerful lasers and special equipment. This enables users to keep the metal AM system on a nearby desk. All images are screenshots of a Desktop Metal webinar that took place March 25, 2021. Register to watch the full webinar at https://gbm.media/mrometalam.

Technical marketing manager Ethan Rejto of Desktop Metal says the top issue the company’s manufacturing clients discuss is the time, cost and effort to start a new production line. Rejto points out that a large portion of this difficulty stems from the lead time and cost of new tooling. Sustaining the line is also a challenge, as manufacturers need to obtain maintenance, repair and operations (MRO) parts to keep the production line going. Additive manufacturing (AM) can provide solutions to both tooling and MRO needs, with Desktop Metal citing its Studio System bound metal deposition (BMD) printer as an effective resource to lower tooling and MRO costs and lead times.

Safe, Compact and Versatile

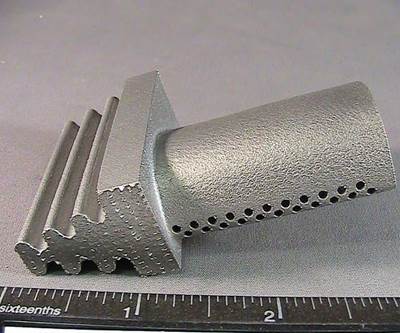

Rejto describes the Studio System (now in its second generation) as “the world’s first office-friendly metal 3D printing system,” and points out that it can operate just across the room from his desk. The Studio System adapts the powder metal supply chain of metal injection molding (MIM), delivering this powder in a less volatile, more accessible form. MIM forms loose metal powder and polymer binder using a mold, then uses a solvent to remove the binder and moves the part to a sintering furnace. The Studio System’s BMD process starts with a rod that includes the same powder and binder already mixed, 3D prints using this rod as feedstock, then uses a sintering furnace to remove all of the binder and give the part its final properties. Without the need for a solvent debinder, or any loose powders or powerful lasers, the second-generation Studio System removes many of the environmental and safety concerns of other metal AM printers.

Desktop Metal recommends the Studio System for low-volume applications like functional prototyping and parts like jigs, fixturing and other tooling, as well as replacement components. The variety of compatible materials includes 17-4PH stainless steel, 316L stainless steel, H13 tool steel, pure copper and 4140 low-alloy steel. Separable supports make the system easy to use, and users can also batch parts together in a single furnace, enhancing operational efficiency.

Additive manufacturing opens up design possibilities that are prohibitively expensive with traditional manufacturing methods. Preziosa Francesco S.r.l. noted that a spring holder hanger it used suffered frequent tearout issues, and so began printing its own, modifying the design to increase the component’s strength.

Capability Across Industries

In a webinar Rejto conducted with us in March of this year, he gave examples of the improvements clients saw in MRO parts printed through the Studio System.

Preziosa Francesco S.r.l. used the Studio System to make notable innovations upon a spring holder hanger. This piece was part of a paneling machine, coupling with a gear through a spring to enable the machine’s arm to rotate pieces of sheet metal. With traditional methods, the shop took seven days to receive the part — longer, if its supplier was out of stock. It also cost €60 per part, and the design suffered from frequent tearout issues. Preziosa Francesco S.r.l. reverse-engineered the part and optimized its geometry within Desktop Metal’s software architecture. When produced through AM on the Studio System, this modified part had a 1-hour-and-40-minute production time, cost only €15 per part, had less material waste and demonstrated increased strength.

Eaton Corporation’s Vehicle Group used the Studio System to produce replacement furnace chain guides — furnace loading and unloading conveyor components that the firm’s external vendors machined and heat treated. After using a 3D scanner to build the model and printing it with the Studio System, Eaton realized 82% cost savings and an extended part life. The system also enabled the firm to realize significant benefits for testing fixtures and gripping components, particularly in the case of a test stand oil fill nozzle. Because AM is able to create complex internal geometries and features at a reduction in cost — as opposed to the increase in expense with standard machining — this part saw even more significant cost savings compared to purchasing from an external vendor using traditional manufacturing: the statistics Rejto provided report cost savings between 94% and 96%.

Before adopting the Studio System, Innovative Plastics Inc. had lead times for molds between to four and six weeks. With the AM system, however, time to part became 5.75 days. Even with the need for some postprocessing, this represented massive efficiency and cost savings for the manufacturer, especially in cases when it needs to make alterations to a mold design.

Innovative Plastics Inc. used the Studio System to change the production method for its molds. Traditionally, the company has used CNC mills and EDM — but even the simplest mold made this way requires lead time between four and six weeks. Performing AM through the Studio System enabled the company to print near-net-shape mold tooling in a fraction of the time, while also adding conformal cooling channels. Without postprocessing (which these 3D printed molds still require), time to part is about 5.75 days. The mold for one part, an exhaust cover cap for a boat motor, traditionally cost between $10,000 and $12,000, with a molding cycle time between 23 and 25 seconds. The AM part reduced costs to between $6,000 and $8,000, with a shortened cycle time of 20 seconds due to conformal cooling. This enabled Innovative Plastics to not only cut costs, but also increase production and revenue.

AM Benefits, Democratized

The compact, office-friendly Studio System metal 3D printer brought the benefits of AM and the digital warehouse paradigm to the doorstep of each of these firms. Lightweighting and other geometric optimizations not only increased the reliability of parts, but reduced costs by using less material. Lead times sharply dropped, and the firms could rely on just-in-time manufacturing from an internal supply chain while maintaining higher equipment uptime. Without the need for hard tooling to make service parts, manufacturers also saved the costs associated with inventory and warehouse space.

Related Content

4 Ways 3D Printing Is Changing Medical Implants

Additive manufacturing provides new ways of making medical implants, but its impact is greater than this. How 3D printing is changing medical manufacturing and improving patient outcomes.

Read MoreThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

Read MoreHow Automation Keeps Quality Control in Control

Collaborative robots help inspection keep pace with machining in a custom, digitalized workflow for complex aerospace and defense parts.

Read MoreUsing Topology Optimization to Lightweight: A Paradox for Machining

Today’s computer software can just as easily generate lightweight shapes for subtractive processes as it can for additive ones, but it increases cost and waste to make them.

Read MoreRead Next

Material Extrusion: Now with Metal

Challenging our thinking about materials in metal additive manufacturing and the possibilities with material extrusion technology.

Read MoreDo's and Don'ts of Finishing Metal 3D-Printed Parts

Finishing 3D-printed parts requires different considerations than conventionally machined ones. One expert offers tips.

Read MoreCan This Metal 3D Printing System Make Production Additive Manufacturing Common in Machine Shops?

A new metal AM system for batches of end-use parts was designed to permit productivity and machine pricing comparable to a CNC machine tool.

Read More

.png;maxWidth=300;quality=90)