Shifting Gears To Integral Drive Adds Productivity

Machines with geared-head spindles are typically employed for machining titanium and other tough materials that require high torque. However, replacing such models with integral-drive HMCs from Makino has enabled this contract manufacturer to significantly improve productivity on time-sensitive aerospace jobs.

Historically, shops have turned to geared-head spindles to obtain the torque required to machine tough materials such as titanium. However, some manufacturers are now discovering that machines equipped with high-torque, integral-drive spindles can provide better results than their more traditional counterparts.

One such manufacturer, Davis Tool, says replacing its geared-head models with integral drive configurations has significantly improved productivity in its titanium machining operations. Combined with an automated pallet system, the shop’s recently purchased Makino HMCs have improved metal removal rates, accuracies and throughput while reducing setup and cycle times.

Founded in 1980 in a 2,000-square-foot facility with a two-person staff, Davis Tool now occupies more than 190,000 square feet and employs more than 140 people. The Hillsboro, Oregon-based contract manufacturer provides a range of machining, fabricating, design and prototyping services to the aerospace, medical and other industries.

"We know our competitors are constantly improving, and to stay a leader, we must do the same," says Ron Davis Jr., executive manager. "We invest in new technologies because it makes our shop more productive than others, and in the long run, more profitable."

In keeping with this philosophy, the shop has invested heavily in automation technology. Mr. Davis says several automated machining cells provide the flexibility and throughput required for the high-mix, low-volume shop to complete jobs quickly. The cells have also significantly reduced downtime, he adds. It was once commonplace for a given machine to sit idle for days after producing a test piece because of the time commitment involved in setting it up, breaking it down and setting it up again. With the ability to retain multiple setups, the shop’s automated cells have largely eliminated this problem. "Each new cell is more productive than the machines it replaced," Mr. Davis notes.

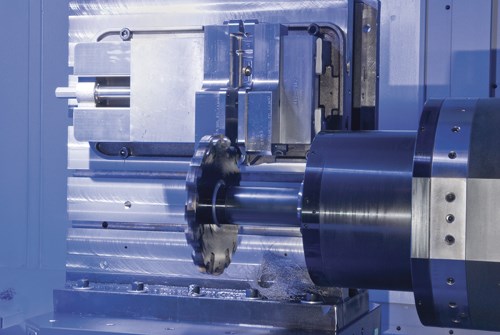

According to the company, that’s certainly true of its latest cell, which is dedicated to machining titanium aerospace components. Consisting of two Makino a82M HMCs with integral-drive spindles and a Makino Machining Complex (MMC2) automated pallet system, the cell replaced five older machines that were equipped with geared-head spindles. The M-package high-torque spindle integrated into each of the HMCs provides 8,000 rpm, 50 hp and 744 foot-pounds (1,009 Nm) of torque. Other features common to both machines include a work zone measuring 43.2 by 32.3 by 40.1 inches and a 300-tool magazine.

The benefits of the integral-drive spindles weren’t exactly an easy sell, however, and the shop did its homework before making the investment. "I’ve been around machine tools for many years, so I didn’t just assume the claim that an integral-drive spindle can perform in high-torque situations was legitimate," says Kevin Brown, programming manager. "Many others in our shop refused to believe that two machines could outperform the five geared-head machines," he adds.

As many aerospace parts produced at Davis Tool are sensitive, non-disclosure components, the company wasn’t comfortable with sending samples out to a machine manufacturer for testing. Thus, the shop performed its own tests, using computer modeling and statistical analysis to compare performance curves of the geared-head machines with that of the Makinos. The tests showed that using high-torque, integral drive spindles would improve acceleration and deceleration rates, increase flexibility and improve tool speeds, while the addition of a pallet-handling system would reduce cycle times. "In fact, we found no performance or efficiency downside to making the switch," Mr. Brown says. "For a shop used to machining titanium with geared-head spindles, that was a surprise."

Since installation, the shop has realized all predicted gains. Overall cycle time on jobs previously produced on the geared-head machines range from 25 to 50 percent. Metal-removal rates have also improved significantly—one job that involved machining an 800-pound titanium block down to 90 pounds took more than 200 hours on the previous machines, compared to 100 hours on the new cell. In fact, Mr. Brown says, metal-removal rates have improved to the point where the shop spends half of what it used to per cubic inch of material removed.

The cell’s HMCs are also able to hold tolerances that were unattainable on the geared-head machines, including true position tolerances of 0.003 inch, dimensional tolerances to 0.0006 inch and milled surface finishes as fine as 32 microinches. Additionally, the cell occupies only half the floor space of the five previous machines. However, despite these improvements, the cell has created a new, unexpected bottleneck for Davis Tool, Mr. Brown says. "We’ve gone from a situation where we couldn’t move parts through the shop fast enough to one in which we’re always waiting on material," he explains. "It’s out of our hands, but our production is running at such a pace now that our suppliers can’t keep up with us."

This has allowed the shop to take on other parts that it might have turned away in the past for fear of losing money on the job or being unable to keep a tight enough schedule to fulfill the contract. Also, the increased metal removal rates enable the shop to promise tight lead times on most jobs. It is currently exploring the possibility of adding a third and fourth machine as well as additional pallets to the cell. "We’re running at 95-percent spindle utilization on the titanium cell," Mr. Brown concludes. "If there’s a problem, it’s that we don’t have more a82Ms."

Related Content

Horizontal Turning Center Ready for High Production

Romi Machine Tools’ new GL300 S features high-power torque and feed force and is built with a robust monoblock base for ultimate rigidity and precision.

Read MoreGrob Robot Cell Enables Long Periods of Unmanned Operation

The GRC-R12 robot cell features a pneumatic single- or double-gripper system, as well as a drawer feed system with six drawers.

Read MoreBest Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)