Tangential Cutter Eliminates Rough-Milling Bottleneck

Ask Jim Rice how that big roughing job is running after retooling, and he’ll talk about doubled throughput, 90-percent lower tooling costs, cleaner plant air and averting a large capital investment. Mr. Rice is the operations manager at Terex’s off-road equipment plant in Ciudad Acuna, Mexico, just across the b

Ask Jim Rice how that big roughing job is running after retooling, and he’ll talk about doubled throughput, 90-percent lower tooling costs, cleaner plant air and averting a large capital investment. Mr. Rice is the operations manager at Terex’s off-road equipment plant in Ciudad Acuna, Mexico, just across the border from Del Rio, Texas.

The “big roughing job” is machining transmission boxes, which are essentially large tubes measuring 9 to 12 feet in diameter and 8 to 10 feet long with walls 4 1/2 to 8 inches thick. One operation involves rough milling about 0.7 inch of Rc32 alloy steel off both ends. Previously it limped along, taking nearly 3 1/2 hours per part, wrecking inserts midway through the cut and occasionally fogging the work area with fugitive mist from the oil-based cutting fluid. Now, the massive parts are done in half the time and inserts last five times longer per edge—with the cutting fluid spigot shut off for good. On a 144-piece-per-year production schedule, annual machining savings from all sources exceed $50,000.

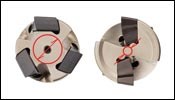

The gains on this job stemm from retooling the plant’s 40-horsepower horizontal mill with an Ingersoll S-MAX tangential milling tool in place of a conventional radial-type milling tool. With the intrinsically stronger inserts and cutters that are characteristic of tangential milling, Terex runs the operation at double the feed rate of the previous tool—30 ipm vs. 15 ipm at the same 0.1-inch depth of cut—with virtually no insert failure. “The inserts never suddenly rupture or crack anymore, they just wear out gradually,” says Roberto Magallanes, a Terex lead man. Based on this success, Terex has switched to tangential milling for all heavy roughing jobs.

Terex’s primary reason for retooling was to speed up the operation in order to free machine time for additional work. Doing this reliably enough to count on extra machining time would allow the company to postpone a big-ticket capital investment in a new machine. The change-over began in July 2007 with help from Terex’s primary tool distributor, Tool Tech Industrial of San Antonio, Texas and was fully implemented the next month. Terex and Tool Tech invited several tooling suppliers to evaluate the operation and suggest a remedy.

Using a 6-inch face mill with conventionally oriented inserts, Terex could muster a feed rate of only 15 ipm. At that rate, completing the part took 3.15 hours and two insert changes. Even then, the surface finish was a barely acceptable 125 rms. Despite the use of oil-mist coolant, the cutter ran so hot that the operator had to wait for it to cool before replacing broken inserts. The cutter ran at 600 rpm with a 0.1-inch depth of cut.

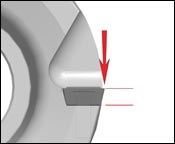

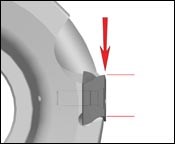

To remedy this situation, two of the suppliers proposed the same type of tooling solution, which promised only marginal improvements. A third supplier, Ingersoll, suggested its S-MAX tangential milling cutter. The tool’s inserts are aligned to lie flat around the cutter’s outer diameter rather than protruding out along its radius, as is the case with conventional tools. In this configuration, each insert’s thickest, strongest cross section absorbs the brunt of the main cutting force. In addition, the tool body is stronger because tangentially oriented inserts can fit into smaller seat pockets that require less metal removal from the cutter body itself.

|

Company: Terex |

With Ingersoll representatives looking on, Mr. Rice and plant manager Jorge Robles began a trial for the tangential cutter at the end of the second shift, fiddling with machine parameters to optimize the operation. By the end of the third shift, the team settled on an 8-inch-diameter model running at 125 ipm, 0.1-inch depth of cut and 600 rpm with no cutting fluid. Under these conditions, throughput improved by about 75 percent and insert edges lasted through 1.5 parts—about five times longer than the previous edges. Subsequent tweaking brought the feed rate to 30 ipm, which more than doubled throughput compared with the old method.

"Most importantly, the operation ran reliably faster, with edges lasting reliably longer,” Mr. Rice says. “It was the kind of improvement we could count on at production and budget planning time.”

In addition to the inherent sturdiness of the tangential cutting geometry, Terex benefited from a PVD-applied TiAlN coating with more lubricity than the CVD coating applied to the shop’s previous inserts, says Ingersoll’s Anthony Myers. The previous inserts required the CVD coating to be applied over honed edges, which were not as sharp as the tangential inserts’ pressed edges.

A further indication of more efficient cutting action is the way heat is distributed during machining with the tangential tool as opposed to the previous cutter. While the chips are hotter than before, the cutter and inserts are merely warm to the touch, even after a full roughing pass. That’s because heat is generated in the workpiece material, softening it at the cutting point before leaving with the chips, Mr. Myers explains. “They say heat is the enemy at the cutting edge, but here it’s an ally,” he says. “It’s all in where you put the heat.”

Read Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)