The ABCs of PECM

Kennametal is advocating Precision Electrochemical Machining (PECM) for lower cost per part, low electrode wear, fewer material hardness concerns and other benefits in producing complex geometrical shapes in metal.

According to Patrick Matt, product manager at Kennametal Precision Surface Solutions, Precision Electrochemical Machining (PECM) is an electrochemical cavity-sinking erosion process with oscillating electrodes and a regulated working gap. The technology first emerged in the 1990s, exclusively for adding fine details in razor blade manufacturing. Machines for other applications appeared on the market in 2006.

PECM applies a pulsed direct current between the electrode and the workpiece, which dissolves anodically in accordance with the geometry of the subsequent electrode. It follows the same processes as electrochemical machining (ECM), using a non-static cathode that travels into the anode and maintains a constant, tiny gap (ranging to 10 microns) throughout the complete cycle time. This produces complex geometrical shapes in practically all electrically conductive metals, the company says, including highly-tempered steel, rolling bearing steel, powder-metallurgy steel and super-alloys. PECM lends itself to applications that could not be manufactured feasibly, if at all, in the past.

Shaping, drilling, or micro-structuring on external or internal areas are typical applications PECM can achieve efficiently. In terms of tolerances, the process is able to achieve quality in a 2 to 5-micron range. Roughing, finishing and polishing are typically combined into one operation, streamlining production.

Mr. Matt says the key features driving the adoption of PECM include:

• lower cost per part

• negligible electrode wear

• no material hardness concerns

• reduction in steps such as shaping and deburring.

Freedom of design is also important, since PECM addresses a wide range of shapes and features that aren’t achievable via conventional machining processes, and repeatability. Part performance is also improved, since neither mechanical nor thermal stress loads are applied to the workpiece.

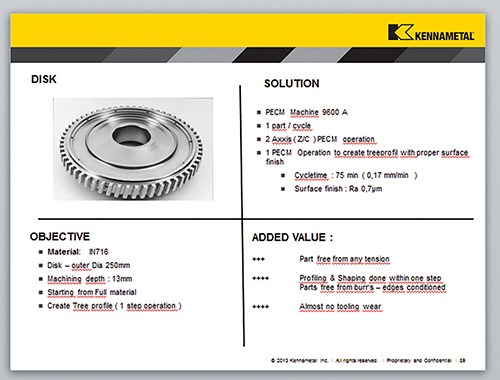

For the past three years, Kennametal and German company PEMTec have partnered in providing PECM equipment to manufacturers located around the world. “We now have a machine equipped with a rotary table so that we can combine the vertical axis and rotation of the part to machine the fir tree slots of an aerospace disc, for example,” says Bruno Boutantin, global marketing manager at Kennametal. “We can complete a disc up to 400-mm OD in a single operation, in fact.”

Kennametal says that PECM has the ability to become more than a niche technology, as it delivers precise products with almost no postprocessing effort. In many instances, the process can provide lower-cost part production compared to traditional machining.