The Basics of Bar Pullers

Bar pullers are cost-effective alternatives to enable automated turning on CNC lathes. Learn how they work and how shops can benefit from using them.

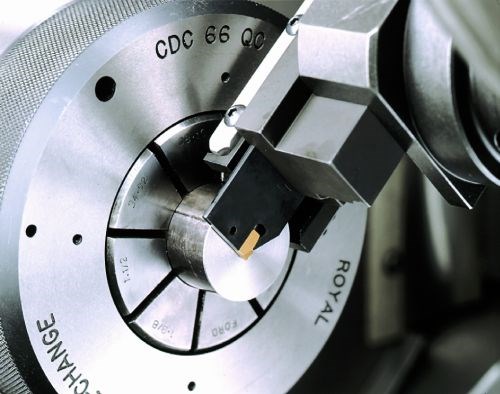

This combination bar pulling unit incorporates a cutoff tool so it occupies only one lathe turret station and eliminates an index from tool to puller.

There are multiple ways to automate a CNC lathe. If your goal is to gain lengthy stretches of unattended operation, then a bar feeder is hard to beat. Conversely, a bar puller is a cost-effective alternative for automated turning of small or medium batch sizes. That’s because a puller can free up sufficient time between bar changes to enable a single operator to tend multiple machines, measure critical part features or perform value-adding secondary operations. The resulting labor cost savings can quickly pay for the puller, as explained in this past article.

Related Content

-

View From My Shop Video 1: A Deep Dive Into Automation with Advance CNC

Advance CNC leverages multiple forms of automation to increase its milling machines' productivity. Learn more in this episode of The View From My Shop.

-

Modern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

-

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

.jpg;width=70;height=70;mode=crop)