The In-House Advantage

A shop that introduced its own product realizes the advantages of designing and machining a part under the same roof.

Reid Machine is a job shop. The startup business in Lake Elsinore, California exists to help companies meet their machining needs. That is why there is some irony in the fact that when owner Darrell Reid designed and introduced his own standard product 3 years ago, he discovered the value of relying on in-house production.

Mr. Reid is not just a shop owner, but also a drag racing enthusiast. The product idea arose from that interest. He says he would spend time at races looking for ways to serve this industry. Chatting with racing teams, he asked them which parts of the cars they struggled with, and which parts failed frequently and had to be replaced.

He asked, “What component do you need to perform better than it does?”

The answer he heard repeatedly was the rocker arm.

A rocker arm is a small part that opens a fuel system valve through camshaft rotation. Racing teams regularly replace these arms because they are prone to fail after a small number of runs. In response to this need, Mr. Reid set about developing a stronger, more resilient rocker arm machined out of solid, heat-treated 4340 steel.

Now, various rocker-arm part numbers account for about 40 percent of business for Reid Machine, which produces the parts alongside its contract machining work. Making these parts to fill the company’s own inventory might seem like an exercise similar to machining parts for an external customer, but Mr. Reid says there is a significant difference. With the rocker arms, he says, he knows the design. He made the design. As a result, he knows precisely how important or unimportant every machined dimension actually is.

“Only certain features of this part have to be dead on,” he says. Other features offer more design leniency. They can be altered to varying degrees without affecting the part’s performance. This freedom aids manufacturing, he says, because the form of a surface or the placement of a detail might be shifted whenever the change could simplify manufacturing—either by making a setup easier or permitting a faster cut. Job shop work practically never includes this kind of in-depth understanding, because the part is someone else’s. When the shop knows the part well, however, the inside knowledge permits more efficient production.

Yet another advantage of in-house manufacturing is captured in that very word—“production.” Job shop work is typically short-run, he says—often prototypes. His shop is ready for this work and does it quickly. But the rocker arms, because they are recurring parts that need to be machined for inventory again and again, provide greater opportunity to refine the process for greater efficiency. In fact, the process improvements he discovers for these parts can end up helping the job shop work. Perhaps the best example of this is the way the shop has come to rely on a software feature that helps the shop to realize more of the capabilities of its machines and tools.

Stream of Chips

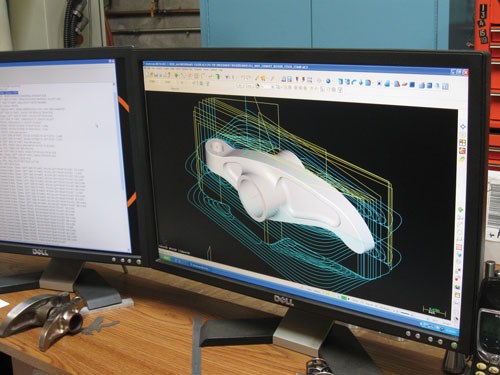

The rocker arms today are run in multiple pieces per setup on Haas Automation vertical machining centers. Solid blocks are affixed around a four-face indexer. The savings Mr. Reid has found by improving setup time (thanks in part to some techniques he prefers not to share) have accounted for a large part of the efficiency improvement these parts have gained over time. But a comparable share of efficiency gain has come from faster cutting, and he credits much of this to his CAM software, Mastercam, and specifically its Dynamic Mill feature.

“I discovered just how effective my machines and tools could be at taking a full-length depth of cut,” he says. The full-length cutting now figures frequently into job-shop machining, too.

The Dynamic Mill feature focuses on milling with the entire tool in this way. The capability enables this cutting in part by charting tool paths that keep the load on the tool consistent—a priority that often produces some counterintuitive tool moves. With this software feature, Reid Machine can often use a 1/2-inch-diameter cutter at a 0.100-inch width of cut, running at 40 ipm through the hardened steel. A stream of chips pours off the tool. Keeping the load continually steady avoids sudden increases in force, and it is these sudden increases (not the baseline force on the tool) that cause cutting performance to degrade. Thanks to the consistency, the shop can run so much faster that a milling cycle once requiring 33 minutes has been replaced by one that takes 7 minutes.

Another productivity-enhancing discovery has to do with the number of flutes used in this full-flute-length cutting, he says. An end mill with five flutes seems to work much better than one with four. With four flutes, he says, there is enough distance from one flute to the next that the effect is like slapping the material. With the five-flute tool, the slightly closer cutting edge spacing is just enough to keep multiple flutes always engaged with the material. The performance difference is pronounced, producing a smoother cut.

Related Content

Watchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

Read MoreChoosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

Read MoreGrinding Wheel Safety: Respect The Maximum Speed

One potential source of serious injury in grinding comes from an oversight that is easy to make: operating the wheel in an over-speed condition.

Read MoreVolumetric Accuracy Is Key to Machining James Webb Telescope

To meet the extreme tolerance of the telescope’s beryllium mirrors, the manufacturer had to rely on stable horizontal machining centers with a high degree of consistency volumetric accuracy.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More.jpg;maxWidth=970;quality=90)

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)