The Key to Repeatable 3D Printing? Materials

The latest issue of Additive Manufacturing Magazine explores how materials will be the key to production 3D printing.

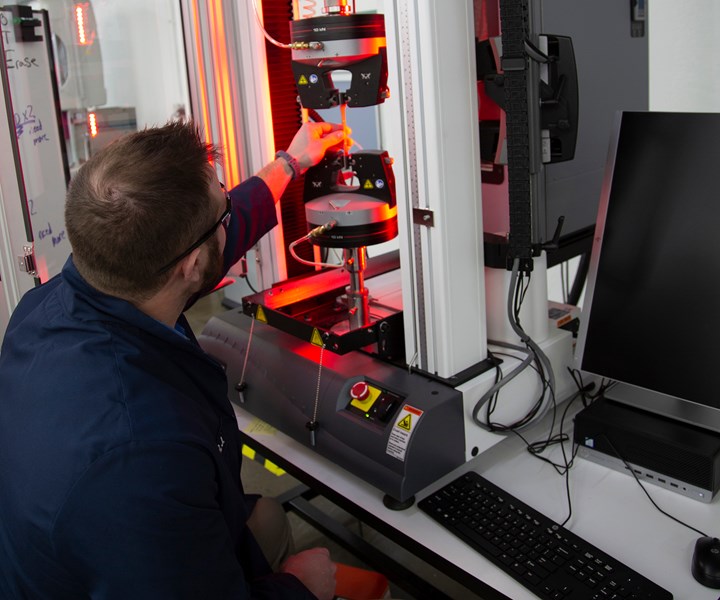

Developing, testing and manufacturing materials for 3D printing will be necessary to advance the technology into full-scale production.

Both Modern Machine Shop and sister publication Additive Manufacturing have covered plenty of examples where 3D printing is being used to manufacture real, end use parts. It is already being applied to manufacture jet engine parts, medical implants, milling tools, rockets and more.

But what’s holding additive manufacturing (AM) back from its holy grail, full-scale production? One of the biggest hurdles to overcome is materials. Reliable materials, with proven print profiles, will be needed — in adequate quantities — if AM is to reach this next stage.

The September issue explores how materials will enable production via additive manufacturing.

The September/October issue of Additive Manufacturing Magazine details how various organizations who recognize this challenge are dealing with it. Stories in this issue include:

- Research by the National Institute for Aviation Research (NAIR) to build out a database of materials and process information for AM.

- How Jabil, one of the world’s largest contract manufacturers, is not only developing new 3D printing materials but working to ensure a reliable supply chain for mass production.

- Evidence that 3D printed polymer parts can outperform molded ones for a common requirement.

- A hybrid manufacturing strategy that combines an unusual material, topology optimization and interlayer laser peening.

- Recommendations for improving operator safety in the face of emissions from polymer 3D printing.

Read it here and subscribe to receive the next issue in your mailbox or inbox.

Want to learn more about 3D printing?

Sister publication Additive Manufacturing explores how manufacturers are applying 3D printing to make tooling, molds, functional prototypes and end-use parts. Subscribe.

Related Content

-

4 Ways 3D Printing Is Changing Medical Implants

Additive manufacturing provides new ways of making medical implants, but its impact is greater than this. How 3D printing is changing medical manufacturing and improving patient outcomes.

-

An Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

-

5 Tips for Getting the Most From the Historic Return of North America’s Biggest Manufacturing Event

Plan. Explore. Think of the future. And oh yeah, the shoes. Here is how to get the most from the major manufacturing event that none of us have experienced in four years, and that many will be experiencing for the first time.

.jpg;width=70;height=70;mode=crop)