The Value of a Photo

Per the common adage, much can be communicated in just one shot.

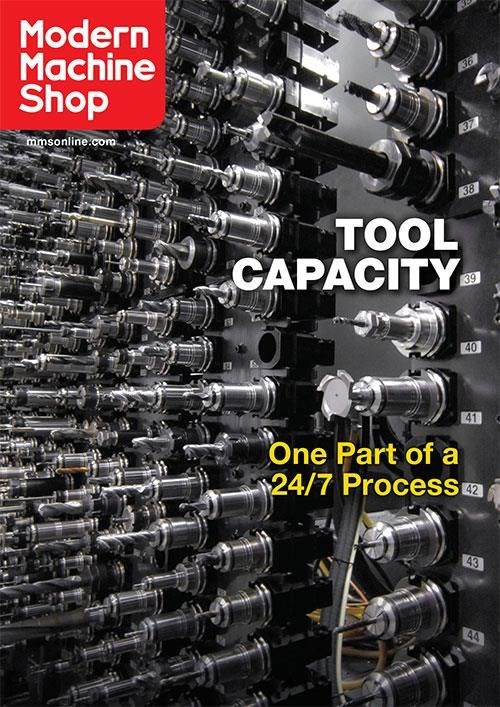

In my humble opinion, I think the cover photo shown above that I was able to take for our October issue was pretty cool. It punctuates the notion that significant tooling capacity is one necessary part of an effective 24/7 machining process (and this article explains R&G Precision’s efforts in that regard).

But there was another photo I took, the one below, that also captures a lot in one shot.

It shows the tool crib area located behind R&G’s HMC cell that has an efficient layout enabling operators to quickly prep tools and material for upcoming jobs. This area includes a Zoller Smile 400 presetter, a Rego-Fix benchtop hydraulic press used to insert or remove collets from Rego-Fix Powrgrip toolholders, a saw to machine blanks, and carts to contain all the tools and material needed to load a job into the cell or one of the shop’s stand-alone machining centers. Plus, one of the shop’s machine operators is also a programmer, and his programming station is just outside this shot. This enables him to set up new jobs as well as create CAM programs on the shop floor.

Putting together words and sentences and paragraphs to tell stories like R&G’s is one thing I enjoy, but the challenge of capturing supportive, telling photos during a shop visit is just as fun.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)