The Value Of Indexable-Insert Center Drills

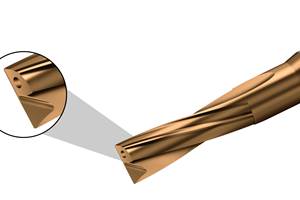

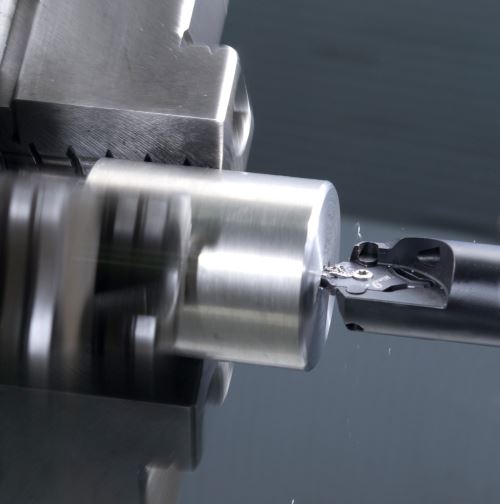

This indexable-insert center drill, said to be an industry first, combines the drilling performance advantages of solid carbide with the positioning repeatability and quick-change benefits common to indexable-insert tooling.

Related Content

Walter Launches New Solid Carbide Drill

The DC118 Supreme solid carbide drill provides high rigidity against deflection, superior centering accuracy and four margins with corner chamfers.

Read MoreKay Engineering's Gundrilling Machine Performs Range of Operations

Kay Engineering’s DeHoff 20144 is used to perform gundrilling, pull boring, roller burnishing and thread tapping.

Read MoreWalter Extends Line of Precision Boring Tools

The new boring tools employ modular components such as cartridge holders and extensions, which are matched to the system, utilize an extensive range of indexable inserts suited for precision boring and can be used for all material groups.

Read MoreWalter Offers New Solid-Carbide Taps for Blind-Hole Machining

Walter’s TC388 Supreme and TC389 Supreme feature patent-pending cutting geometries that fully shear off the root of the chip when reversing, thus minimizing torque peaks.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)