Honing technology keeps evolving, whether it’s for long bores or short ones. Honing can take a so-so bore and make it perfectly round and straight, with end-to-end diameter precision, and do it with process capability of 2 Cpk and higher. Honing can correct errors in bore geometries such as barrel, hourglass and others. Honing can precisely size a bore diameter within tenths of a micron. Honing can create a surface-finish profile to meet an array of advanced specifications (such as Rvk, Rpk and Rz) and plateau—a capability used to improve engine efficiency and emissions. And to the surprise of many, honing can remove significant amounts of stock to enlarge bore diameter, as demonstrated in oilfield shops. So who needs this capability?

Fred Feddersen for one. He is a rifle barrel maker on a mission to do something that he believes has never been done before: create a production barrel that can shoot successive bullets through the same hole using an inexpensive semiautomatic rifle, not a bolt-action Olympic race gun. He is squarely on target to hit this goal using the latest in tube-honing technology. The HTC-series tube honing system from Sunnen Products (St. Louis, Missouri) can impart accuracy-enhancing bore geometry and size (±0.00005 inch end-to-end) with a finish of 3 to 8 microinches Ra—fine enough to shed fouling and copper bullet-jacket residue. The hone’s servo-spindle also serves as a quality check on reaming, he says. Its extreme sensitivity to spindle load enables it to detect and correct light and loose areas in the bore that escape most air gages. He suggests this advanced honing equipment and know-how could also be applied in the manufacture of other small-diameter, super-accurate tube applications.

Tube honing isn’t the only metalworking operation that Mr. Feddersen took to new limits to get remarkable rifle barrels. He also developed new ideas for gundrilling and reaming. However, what he’s done with honing technology tells a better story of his distinctive approach to similar applications in which long, super-accurate holes are a challenge.

FROM BOTTLES TO BARRELS

Mr. Feddersen is a design engineer and inventor who does not accept current limits on any technology, whether it is welding or bottle blow-molding. His varied interests and career moves have led him to learn Morse code, pass the FCC exam, earn seven welding certifications and become a CNC programmer. Some of his most widely used inventions were developed for blowmolding PET bottles.

After success in that industry, he sensed a market opportunity about 10 years ago to make ultra-accurate rifle barrels in high volumes for military and commercial use. After studying the art and science of custom barrel making, closely examining the industry’s best barrels and acquiring high-precision machine tools, Mr. Feddersen launched RFour. This decision involved a move from his original location in New Hampshire to Loudon, Tennessee, where he built a new factory. It houses a number of CNC machines, including lathes, vertical and horizontal machining centers, gundrilling machines and heat-treating ovens for stress-relieving steels. (The company occasionally takes on outside machining work, too.)

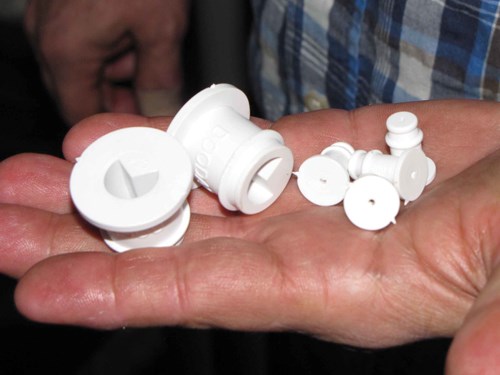

During RFour’s first years, he spent much of his time and effort pushing past the known limits of barrel manufacturing technology to achieve his goal, starting with improvements in gundrilling and reaming. For example, to push straightness beyond the accepted norm for gundrilling runout, Mr. Feddersen came up with new ideas for drill design. He developed capabilities for push-reaming long, small-diameter bores (as small as 0.17 inch in diameter) with 0.0001-inch accuracy. He also invented and patented a new style of whip-guide stabilizer, which is injection molded at his plant in a range of sizes and sold to the industry as a commercial product line.

In fact, Mr. Feddersen suggests that what he’s learned about barrels applies to similar tube-

type products that require reaming or honing very small holes (as small as 2 mm). These include stents (prior to laser cutting into spring formations) and waterjet cutting nozzles. The latter must be free of internal surface micro cracks, which can be accomplished by honing them down to the base metal in a process similar to that used for high-pressure diesel fuel rails. However, manufacturing rifle barrels remains the company’s primary focus, which is a challenging and demanding preoccupation in its own right.

PERFECT HOLES mean perfect TARGETS

Barrels start with stress-relieved 4150, 416SS, MIL-S-46047 (a special alloy with extra vanadium) or MIL-S-11595 before rifling. A rifle barrel—before rifling—should have the roundest, straightest, smoothest hole possible, Mr. Feddersen says.

“Straightness of the gun-drilled hole has a profound effect on accuracy, though it is not fully appreciated in the industry,” Mr. Feddersen explains. “If a bullet traveling at Mach 1 passes through a banana-shaped bore with an error as slight as a quarter-mile in radius, it will cause vibration. This matters less with small-caliber bullets than with heavier .50-caliber slugs, but it is always a factor in accuracy.”

This is why extraordinary straightness takes on extreme importance. “When you push a gundrill, if the tube size is standard, it can bend so the drill tip rolls onto its back taper, and the drill will try to steer crooked,” he explains. “To limit this, we specify a tube only 0.005 to 0.007 inch smaller than the drill diameter. The tube can then bend only a couple of thousandths off center, so it maintains a straighter drill path. These design parameters enable drilling 2,000 to 4,000 inches in 32 Rockwell steel at 1.5 to 2.5 ipm in one sharpening. Moreover, runout stays under 0.0005 inch per inch or under 0.016 inch TIR, end to end, on 36-inch, .50-caliber barrels.”

ULTRASENSITIVE HONING SPINDLE DETECTS/CORRECTS ERROR

Mr. Feddersen’s goal with honing is eliminating radial reaming marks and perfecting roundness and straightness. “The HTC tube hone is key for honing small-caliber barrels efficiently and precisely, with servo control of three axes: spindle, tool feed and stroking,” he says. “Its servo spindle motor is so sensitive you can create 50-percent load just by putting your fingertips on the tool shaft. There’s only a handful of these machines in the United States. We also hone only on the pull stroke.” According to Mr. Feddersen, the servo-feed system expands the tool very rapidly at the start of the pull stroke, then retracts it quickly to take load off before a rapid move forward to the start point.

“Elimination of reaming marks gives the tightest shot groups, there is no doubt in my mind,” he continues. “Honing eliminates even the tiniest high spots. If the reaming is not perfect, the torque sensor on the hone immediately senses it. These are high spots that cannot be detected by lapping or reaming. Air gaging, depending on the gage, may not be able to detect it. After honing, our roundness is down to a point where a tenth-reading dial-bore gage barely flutters.”

Smoothness also improves the barrel’s cleanability. “The lower the Ra, the easier the barrel is to clean,” Mr. Feddersen says. “When copper settles in the valleys of reaming marks, it will not come out without a solvent.”

Honing with finer abrasive grits is key to achieving the best roundness. “The finer the grit, the rounder the hole becomes,” he says. “We typically use 600 and 1,200 diamond grit, and we will go to 1,800 in some cases. Lapping cannot improve roundness, but honing can. A bullet passing through a non-round barrel comes out non-round and cannot travel perfectly straight.” A perfectly round hole in the workpiece also gives the best results when adding cut- or button-rifling. “If the hole is suddenly 0.0005 inch smaller or larger in part of the bore, the action of the rifling cutter or button will vary,” he explains.

Mr. Feddersen button-rifles his barrels with carbide buttons made to his specifications for the material formula and profile. Final steps include contouring the OD, chambering and fluting. These are followed by optional stress relieving, lapping and other proprietary steps, per the customer’s order. Lapping, he explains, softens all sharp edges and leaves a final surface finish with a linear pattern, rather than radial.

IN THE CROSSHAIRS OF OEMS

Mr. Feddersen has ample evidence of his progress in a binder full of targets with near-single-hole, five-shot groups. All were fired from 50 yards using a semiautomatic Ruger .22 magnum rifle equipped with one of his barrels. Shooters familiar with this rifle and cartridge know this accuracy is extraordinary, but Mr. Feddersen attributes these results to his extraordinary barrel making. After a decade of development, he is seeing strong interest from firearm OEMs. Most importantly, his company’s capabilities have earned it a role as supplier of choice for barrels used on U.S. military sniper rifles in .50-caliber BMG (Browning machine gun) and .338 Lapua magnum, he reports.

Another measure of Mr. Feddersen’s success is the need for additional manufacturing capacity. In that regard, his company recently acquired two new three-spindle gun drills, a second heat treating oven and an automated cut-to-length/chamfering machine that can produce five barrel blanks per minute.

For the future, Mr. Feddersen has his sights set on other applications that call for extraordinarily high-quality bores. One of the most interesting involves reaming and honing 0.75-inch-diameter bores in 20-foot lengths of beryllium copper for down-hole use on offshore oil rigs. When connected, a stack of these tubes will enable the drillers to lower an electronic sensing device through the tubing into the submerged pipe a mile deep. By holding a 0.001-inch straightness tolerance end-to-end on the bore of each tube segment, along with a very fine surface finish, honing on the HTC machine will ensure that the copper tubing will provide smooth, snag-free passage for the electronic device.

Characteristically, Mr. Feddersen is excited by the prospect of using a “home-grown” reaming tool to ream the bores of these beryllium copper tubes prior to honing. He developed this tool by modifying a solid carbide reamer for more efficient chip clearance when used on a gundrilling machine. “Better, faster reaming means better, faster honing afterward,” he says.

.png;maxWidth=300;quality=90)