Useful Advice for CAM Software Users

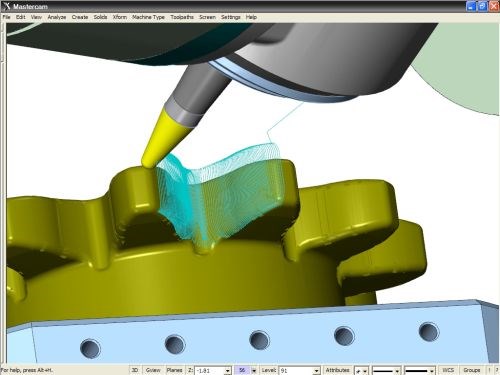

In a whitepaper, Mastercam calls useful advice for CAM software users “CAM Initiatives.” These initiatives are practical projects and procedural policies designed to help a machining company make more effective use of its CAD/CAM resources. Although primarily targeted to Mastercam users, many of these initiatives contain useful advice that benefits users of any CAM software system.

In a new whitepaper, Mastercam calls useful advice for CAM software users “CAM Initiatives.” These initiatives are practical projects and procedural policies designed to help a machining company make more effective use of its CAD/CAM resources. Although primarily targeted to Mastercam users, many of these initiatives contain useful advice that benefits users of any CAM software system.

Here are a few samples:

- Say “no” to drawings. Don’t redraw parts until you are sure the customer does not have a usable CAD file to share. (They usually do.)

- Fix what isn't broken. Empower everyone in the shop to be an improvement specialist.

- Manage tool libraries. Find the cutting tools that work best in high-speed tool paths and use these tools exclusively where applicable.

- Embrace five-axis machining. Follow this launch plan to ensure a successful transition.

Other initiatives have advice on 3+2 machining, programming templates, spindle probes, simulation and integrating safety habits.

For the complete whitepaper with all 15 CAM Initiatives, click here.

Related Content

-

TTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

-

IMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

-

Large-Format Machining With Small Cutting Tools and Dynamic Motion

Napoleon Machine, a defense contractor that provides parts for the M1 Abrams tank, recently took advantage of a CAM feature that allowed the company to streamline its cutting strategies and program offline. Here’s how the shop cut cycle times nearly in half with its large-format five-axis machining operations.

.png;maxWidth=300;quality=90)