Vise within a Vise System Enables Economical Five-Axis Machining

A unique vise-within-a-vise system using Kurt workholding enables Peterson Machining Inc. to cost effectively use five-axis manufacturing for complex parts.

When a shop produces parts that vary greatly and don’t involve longer production runs, it can’t always justify the cost of dedicated fixtures. However, by configuring standard vises from Kurt Industrial Products Division (Minneapolis, Minnesota) into custom workholding setups, Peterson Machining Inc. was able to process its parts faster and in fewer setups than with standard vises alone.

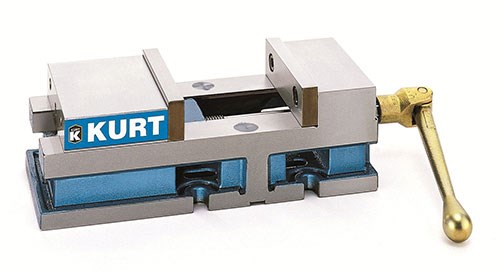

Located in Boulder, Colorado, the contract manufacturer owned by CEO Ronda Turner Peterson and her husband Todd Peterson, COO, supplies leading aerospace, medical and communication OEMs. The company standardized on the use of the Kurt 3600 vise model for virtually all of its workholding needs when it began operations in 1989. With more than 25 Kurt model 3600 vises in the shop purchased over the years, little did the Petersons know that those vises would enable the company to move into cost-effective five-axis machining without reworking or developing completely new workholding solutions.

The need for a custom workholding setup occurred when the Petersons noticed a rapid change in part complexity that required a move into five-axis machining. To address this need, the company decided to purchase two DMU 65 Monoblock machining centers in 2012.

“Those machining centers, together with our other machining center inventory, moved our capabilities into a higher level, but with new challenges,” Mrs. Peterson says. “In particular, there was a continuing need for innovative workholding to maximize the productivity potential within our new machines’ capabilities. Five-axis machining was especially challenging.”

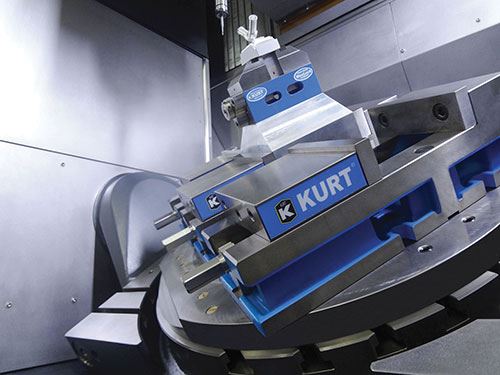

During IMTS 2012, Mr. Peterson began checking out five-axis workholding options, and Kurt’s MaxLock 425 vise caught his eye. Soon, the idea of mounting that vise within one of the Kurt 3600 vises already positioned on the machine table came to light.

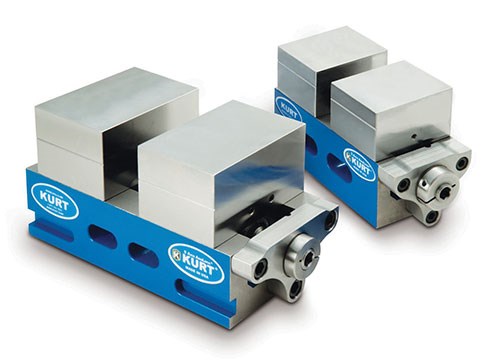

Since Peterson Manufacturing’s projects most often require large amounts of metal removal on smaller parts, the small MaxLock vise model was a perfect fit. It is designed for small-part, continuous five-axis cutting motion of complex pockets, sculptured and contoured surfaces, including intricate 3D features with repeatable ±0.0002-inch precision.

The MaxLock has a self-centering design along with Kurt’s patented Anglock feature. The vise aligns parts and reduces lift to a minimum by pulling parts down and holding them with maximum rigidity for close tolerance repeatability in all axes. The vise clamps both OD and ID and has an adjustable center line. The tall jaws provide increased spindle clearance, and they can be machined to include a “step” that eliminates the need for parallels. The reversible jaws are designed to provide even more flexibility in clamping operations.

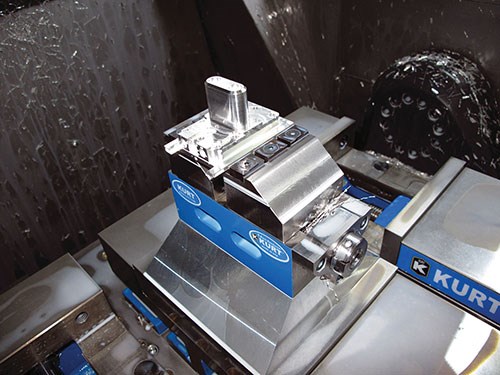

For taller workpieces, Mr. Peterson machined a riser adapter plate that bolts to the bottom of the MaxLock vise. With 5/8-inch dowel holes for fast mounting using sine keys, the vise also has auxiliary clamping slots for mounting flexibility. Unlike most flat and square risers, there is a taper on two sides to allow more spindle clearance for better part access. The tapered feature also facilitates wet chip evacuation so that chips slide easily down and away from the cutting area.

“The extra height we get by combining the height of the receiver vise, the riser adapter, and the MaxLock vise does not compromise the needed rigidity,” Mr. Peterson says. “All three components work well together and don’t impose any undue stresses on the machine.”

Peterson sets up the MaxLock with the custom-made riser the same way on both of its DMU machines. One of the machines features a rotary table with a one-sided drive and brake on the other side. On this machine, a single Kurt 3600 vise is used as the receiver. The second machine is equipped with three Kurt 3600 vises mounted side by side on the machine table with the MaxLock clamped into the middle vise. There is no need to remove the two vises on each side of the MaxLock setup; they stay in place for future jobs. The interchangeability of the receiving vises on both machines is important because it saves setup time.

While it’s not designed specifically to be a receiver for other vises, the Kurt model 3600 has all the needed features. It is precision machined on all sides so the sides are flat and parallel. The vise has 0.0005-inch clamping repeatability, so there’s no zeroing-in guesswork from one setup to the next. Also, the AngLock design prevents the inserted MaxLock vise from lifting upward. The one-piece vise body and stationary jaw provide strength while reducing weight. The MaxLock clamps perfectly inside of it.

As a whole, Peterson Machining has been able to ensure consistent, repeatable workholding accuracy machine to machine through the years by standardizing on the Kurt 3600 model. Mr. Peterson says he likes the predictability, especially when moving the vises from one machine to another due to changing product requirements. As an added benefit, when the company started machining five-axis applications, all the Kurt vises had the necessary features to adapt easily as receiving vises, he says.

The five-axis vise-within-a-vise setup gets regular use machining 6061 aluminum, 7075 aluminum and some stainless steel components such as valve bodies, aerospace and satellite components. These components start as solid blocks of material that are aggressively hobbed out before operations such as drilling, tapping, thread milling, boring and finishing are performed. When second operations are needed, the part can be mounted quickly into one of the adjacent model 3600 vises to machine the bottom or sixth side of the part. Machines speeds vary from 30 to 200 inches per minute at 3,000 to 18,000 rpm, depending on the operation. Tolerances held for most of these machining operations is true position of one to two thousandths.

“New work coming in challenges us to develop better ways to do the work cost effectively and with quality precision.” Mr. Peterson says. “Our MaxLock vise setup is one of many Kurt five-axis vises we plan to add in the future. Modular workholding from Kurt, especially as it continually adds new workholding devices, will give us new options that will please our customers.”

Related Content

Fixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

Read MoreWhen To Use A Collet Chuck

Don't assume the standard chuck is the right workholding for every lathe application.

Read MoreMedical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Read MoreMoving To Magnets Doubles Productivity

Moving from hydraulic to magnetic fixtures enabled this shop to reduce setup time, improve rigidity and eliminate manual operations. As a result, productivity doubled.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)