VMC Helps Shop Find Tight-Tolerance Niche

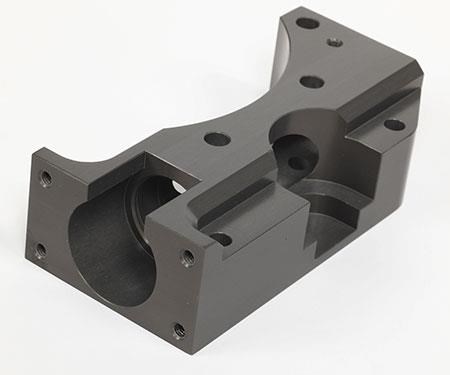

YDC Precision Machine's VMCs needed more capacity and capability, so it invested in a Makino PS95 vertical machining center that cut cycle times in half.

Almost always, a premium machine tool comes with a premium price tag—a concept that gave pause to job shop YDC Precision Machine. Yet, purchasing a new Makino VMC made sense after factoring in the cost of its standard machine options that are considered add-ons on other machines, like through-spindle coolant, a chip conveyor and a high-speed spindle. With this in mind, the price gap lessened significantly enough for the shop to make the investment. The new machine has helped the growing company achieve the capacity required to meet an increased workload, as well as achieve the quality and precision necessary to set it apart from the competition.

Founded in 1983 by owner Yvan Cote, YDC has grown from a one-man garage shop to its current 7,200-square-foot space in Franklin, New Hampshire, performing work for production OEMs in the semiconductor and communications industries, as well as the commercial equipment industry. The company began to feel the pains of its sustained growth while producing ground units for satellites. Recently, it received an urgent order to complete 300 aluminum components for an assembly in one week, but its commodity machining centers could not produce that quantity in time while still meeting the precision requirements. Quality was the company’s primary concern on this part, but its older machines struggled to repeat required tolerances and finishes. This meant frequent inspections and adjusting machine offsets throughout the day. The parts often required more machining time than planned.

After researching new machines, YDC decided to purchase a PS95 vertical machining center from Makino (Mason, Ohio). Not only was it built to last nearly 20 years instead of the 5 to 10 years the shop was accustomed to with its other machines, Mr. Cote says, but it also included features as standard that were considered add-ons by commodity machine suppliers.

“In reality, these features should be standard on every machine, because that’s the level of quality and machinability that is needed for small job shops to compete,” says Kelly Cote, Yvan’s son.

Features like through-spindle coolant, a spiral-chip conveyor and a lift-up chip conveyor have eased YDC’s concern about re-cutting chips, and they’ve helped improve efficiency in roughing and drilling operations by enabling the company to take more aggressive cuts.

The first parts the company ran on the new PS95 included the ground-unit components. Right away, throughput improved by 50 percent, Kelly says. For a job shop like YDC, every second counts, and every extra part per hour had the potential to generate a lot of extra revenue, he says. With some components, the company was able to nearly double its feed rates compared to what was achievable with its older VMCs.

Fast tool changes also contributed to these results by reducing out-of-cut time. Also, the new machine enables rigid tapping, which enables the shop to do without an expensive tapping head—a good solution, as the shop produces these types of holes infrequently.

In one roughing application, the company’s previous VMCs would pause in machining corners, but the PS95 transitions easily through them, because the machine’s control is always

looking ahead in the process, anticipating what is next. According to Kelly, this helps increase precision, especially when machining a slot that is 0.060-inch wide and requires ±0.0005-inch tolerance, for example. The shop no longer has to slow the speeds and feeds to achieve the required accuracy.

Another benefit of the new machine is improved surface quality on primary machining passes. The shop no longer needs to take two cleanup passes to address deflection. This has eliminated unnecessary programming, tool degradation and labor costs, leading to shorter cycle times and greater profitability. It is especially helpful because YDC operators tend multiple machines at a time.

Kelly says he is impressed by the machine’s initial performance, which has been solid and repeatable. For instance, he says he can run a part through the machine all day long, and the last part will come out with the same accuracy as the first. He no longer needs to “babysit” the machine and check parts frequently.

Yvan agrees “It used to shock me that machining on the PS95 takes less time but yields better quality. I wish that I had three of these machines right now, rather than our three other vertical machining centers.”

To keep up with the productivity of the PS95, YDC recently invested in new fixtures to accommodate additional parts for each setup. This has helped eliminate spindle downtime between part loads, limiting the amount of labor required and enabling operators to focus on maintaining other machines’ performance.

Additionally, the operators no longer need to track maintenance themselves, because the PS95’s maintenance reminders indicate when service is required. This is a helpful tool because operators are constantly moving around the shop floor, trying to push as much productivity as possible, Kelly says.

According to Yvan, the biggest benefit of the new machine is that YDC can now accept work that it used to pass on, enabling the business to continue growing.

“This technology has taken us to a higher level, where we can meet very tight quality standards. We can now hold tolerances to the tenths, which gives us new opportunities,” he says.

The PS95 has enabled YDC to produce parts that bigger companies can make, but with a lot less overhead, Yvan says. Since getting a taste for the bigger jobs, YDC plans to continue producing high-end products as it grows.

“We hope to someday find a niche in meeting tight tolerances,” Kelly says. “And as we continue to expand, we will need additional machines to meet that growth. When this happens, we will definitely invest in another PS95 or even a Makino horizontal machining center.”

Related Content

Heavy Engineering: The Complex Logistics of Moving Large Machine Tools

One of our fascinations with large-format machine tools has little to do with their capabilities, but everything to do with the logistics involved with getting them up and running. Here’s how one of the world’s oldest builders of giant machine tools tackles the challenge.

Read MoreThree-Axis Bridge Mill Opens New Doors for Construction OEM

Different industries often require different machining priorities, a truism recently demonstrated by Barbco, an OEM of heavy-duty boring equipment that opened up new design possibilities by pivoting toward rigid, less complex machining centers.

Read MorePositioned to Prevail: Designing Processes Around People

Stecker Machine Company shows that getting the most value from employees means valuing your employees.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)