Robotic automation and additive manufacturing (AM) both have the potential to transform how parts get made and how businesses operate. The addition of a cobot or other robot allows a business like a machine shop to devote less human attention to tasks such as loading and unloading workpieces; this move might then lead that business to pivot to lights-out production for greater productivity. Likewise, a manufacturer might add 3D printing capability to make jigs and fixtures, but later discover its applicability for producing end-use parts and find new business opportunities there.

Yet robots and additive manufacturing do not run in parallel tracks. Their paths frequently intersect, often to great advantage. Here are four ways that robots and 3D printing support and enable each other:

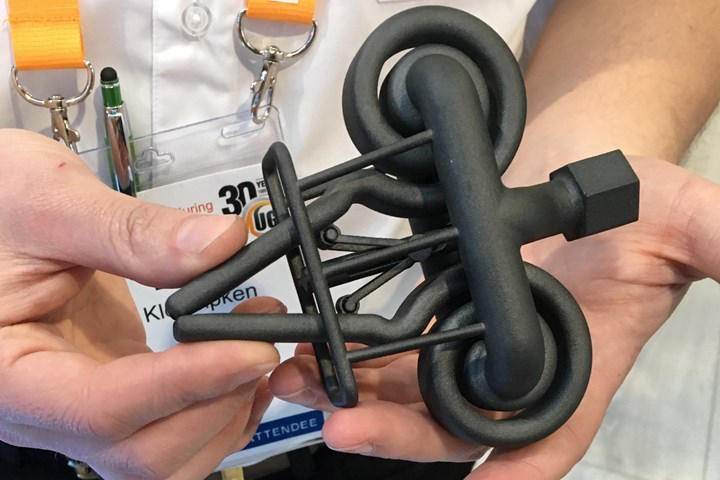

1. 3D Printed End-of-Arm Tooling (EOAT)

Vacuum grippers, jaws and other end-of-arm tools for robots are a perfect application for the design freedoms 3D printing offers. 3D printing makes it possible to build functional grippers in just one piece, incorporating air lines, live hinges and other complex features without assembly (see below). Topology optimization strategies or simply the chance to create robot tooling out of plastics versus metals can provide weight savings, preserving more of the robot’s payload for the parts. Bringing robot tooling in-house via 3D printing is also an affordable option for producing these items, with potential time savings to boot.

This robot gripper made by IAM 3D Hub through Multi Jet Fusion demonstrates how moving parts can be incorporated into a 3D printed end effector. A pneumatic mechanism operated via shop air squeezes the jaws closed as shown here. More.

2. 3D Printed Off-Robot Accessories

Of course, the robot end effector is only one piece of the overall system needed to automate a given operation. Custom trays, jigs, fixtures and more may be needed to serve up parts in just the right way to the robot, or to collect parts after they have been processed. Here again, 3D printing provides a fast, simple way of building creative solutions around the robot automation which can be done in-house with an affordable polymer printer.

Superior Metal Products designed and 3D printed this collection chute to allow for manual part inspection without stopping the operation of its automated turning cell. More. Photo Credit: Superior Metal Products

3. Robot-Tended 3D Printers

There are also ways for 3D printing to benefit from integration with robotics. The additive manufacturing process consolidates various workflow steps into one machine that can run unattended for long periods of time. Rather than time shifts and adjust schedules to accommodate 3D printer unloading, manufacturers can use robots to remove finished parts, place new build plates, and continue printing even when no humans are present.

This cobot at plastics manufacturer Evco tends a bank of polymer 3D printers that produce tooling as well as end-use parts. When a build complete, the robot removes the part, places a fresh build plate in the printer, and uses a stylus (pictured) to start the print cycle again. More.

4. Robots As 3D Printing Systems

In addition to being a valuable means of moving parts and supplies, robots can also serve as the method for applying material in a 3D printing process. Options for robotic 3D printing include polymer extrusion, wire arc additive manufacturing, metal powder directed energy deposition (DED) and even heat-free supersonic deposition. A 3D printing head mounted on a robot arm has more freedom of motion than one fixed in a gantry, and can enable support-free 3D printing and complex geometries that might not otherwise be possible. (The reverse is also possible — that is, keep the printhead stationary but mount the build plate on a robotic arm for geometric freedom.) Robots can also be mobile, and can achieve a much larger effective build volume by being mounted on a track or moved on site to produce structures in situ. Multiple 3D printing robots can even be coordinated to print together, operating in a swarm or a choreographed dance to speed production and create large parts more quickly.

Addere has developed a robot-based directed energy deposition (DED) system for 3D printing of large metal components. The laser-based process works in an enclosed environment, monitored by cameras in an adjacent room. More.

Related Content

Niche Work If You Can Get It: A CNC Machine Shop Crafts Its Own Destiny

The latest innovations in metalworking aren’t always related to CNC automation or robotics. For Rosenberger North America, a 2022 Top Shops Honoree, it is the company’s niche processes that create the biggest successes.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreWeiler to Debut New Automation Features For Its Lathes

Weiler’s V 110 four-way precision lathe introduces features new to the U.S.

Read MoreView From My Shop Video 1: A Deep Dive Into Automation with Advance CNC

Advance CNC leverages multiple forms of automation to increase its milling machines' productivity. Learn more in this episode of The View From My Shop.

Read MoreRead Next

Meet the Automation That Makes Machine Tool Automation

A new manufacturing cell at Mazak’s North American headquarters is one part machine tool production unit and one part demonstration facility. And it’s here to provide a lesson about how automation can tackle skilled-worker shortages and supply chain issues at the same time.

Read More3D Printed Fixtures Speed Setup for Inspection

3D printed fixtures enable this company to quickly set up parts for CMM inspection, whether it's a one-off or recurring job.

Read MoreHow Robots and Additive Manufacturing Work Together

The July issue of Additive Manufacturing magazine takes a close look at the ways automation and AM overlap, from part handling to 3D printing with robotic arms.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)