When to Use a Diaphragm Chuck

The accuracy and repeatability of these chucks make them well-suited for a number of workholding applications.

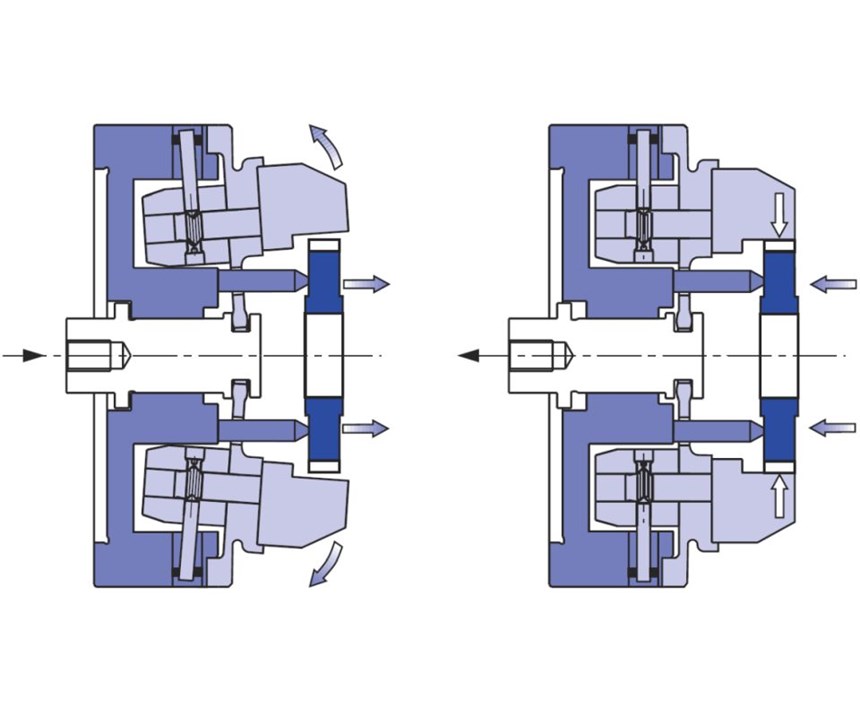

Ron Shibovich, director of engineering for SMW Autoblok, says a diaphragm chuck for a turning center functions similarly to a human’s diaphragm that contracts and retracts to draw or “suction” air into our lungs. He says unlike standard chucks that rely on the wedge and master jaw linkage for clamping, a diaphragm chuck applies the principle of elastic deformation in expanding, contracting and using resistance to hold workpieces in place. Because diaphragm chucks don’t have sliding components, they don’t require lubrication and offer a more consistent grip force repeating to within 10 microns.

Mr. Shibovich explains that the accuracy and repeatability of these chucks make them well-suited for a number of workholding applications, including:

- Hard turning of gears. After gears are machined and then heat treated, manufacturers typically would grind each gear’s bore to ensure it is true to the tooth form pitch line. The centering accuracy of the diaphragm chuck, however, enables manufacturers to eliminate this grinding process, reducing cost and production time. In fact, the diaphragm chuck was originally developed for this specific application.

- Centering accuracy for secondary operations. For more efficient turning, shops often use hard, serrated jaws to clamp raw material in the first turning operation. Using a diaphragm chuck for the second operation offers repeatable centering accuracy when clamping onto a part’s machined surface.

- Gears with thin walls. Diaphragm chucks typically are not recommended for thin-walled applications due to workpiece deformation that could be caused by the clamping forces. However, the SMW Autoblok D-Kombi diaphragm chuck provides radial centering and clamping of the workpiece in conjunction with swing clamps for axial clamping (in addition to the diaphragm clamping force). By distributing the forces axially across the part, the workpiece is less likely to be deformed radially.

Mr. Shibovich says SMW Autoblok diaphragm chucks offer the ability to swap jaws in minutes. They also provide a center locator creating a Z-axis plane to adjust for gear height and diameter variations. These features allow for overall increased productivity in addition to the accurate, reliable and repeatable nature of the diaphragm chuck itself.

Related Content

-

A Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

-

Machining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

-

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)