Workholding That’s on Point

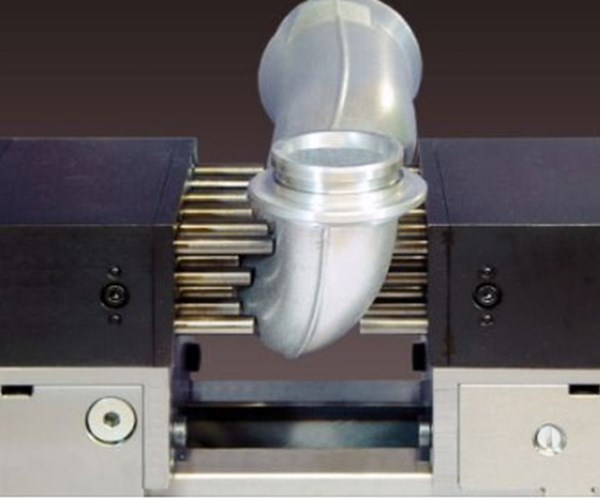

A pin-based workholding system quickly accommodates workpieces of any shape.

Did you or one of your kids ever play with one of those pin impression boards? The idea was that you could press any object—a smaller toy or a hand, for instance—gently into the pins on the back of the board and see a crude relief image on the other side.

A clamping element from Euro-Tech called “The Jaw” (pictured above) works in a very similar fashion. The product has a number of hydraulic pins on each side that quickly conform to the shape of any part placed between them. Internal clamping sleeves lock the pins in place, and the company says that the form fit reduces required clamping force. The adaptable system can be used as jaws for vises, as supports, and in combination with robot grippers and other custom solutions.

Related Content

-

Simple Workholding for Robotic Automation

Robotic automation relies on reliable workholding, and these modular pneumatic jaws make it simple.

-

Modern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)