MMS Blog

The Softer Side of Robots: Increasing Automation’s Adaptability

Robotic applications are expanding thanks to rubber and silicone-based systems that can handle fragile materials or parts in varying sizes and shapes.

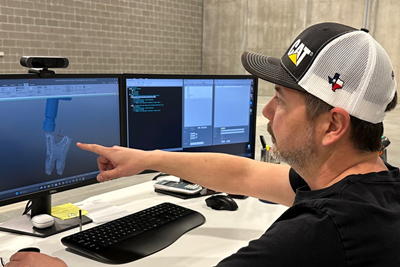

Read MoreDigital Transparency in Machining Key to Multi-Site Additive Manufacturing

Cumberland Additive’s CNC programmer in Pennsylvania spends most of his time writing programs for machine tools in Texas.

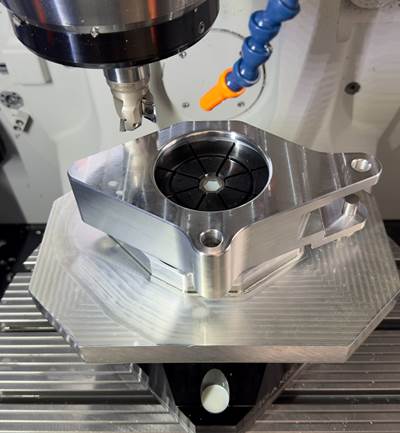

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreProtecting Your Automation Investments

Shops need to look at their people, processes and technology to get the most of out their automation systems.

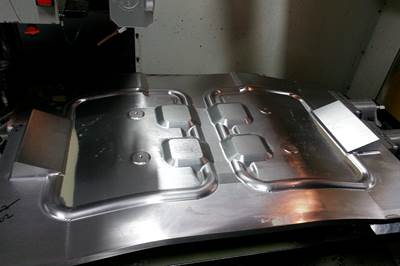

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

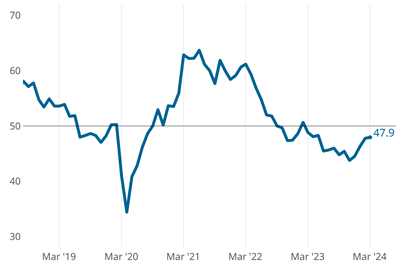

Read MoreMetalworking Activity Holds Steady in March

Overall metalworking activity leveled off in March, but not to a point of concern.

Read MoreAbrasives Supplier Provides Automation Consultation

Recognizing the demand for automation solutions in grinding and finishing applications, this abrasives manufacturer is providing free consulting services to help shops develop automated processes.

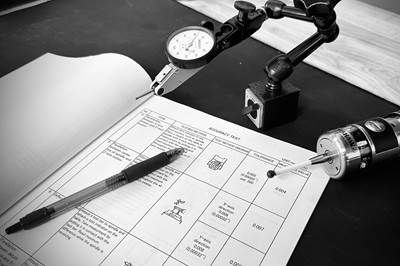

Read More5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Read MoreHenkel Redefines Industrial Machining and Grinding with Sustainable Metalworking Innovation

With innovative formulation and bio-resistant properties, Henkel’s new semi-synthetic lubricant emerges as a pioneering solution in the machining industry.

Read MoreManufacturer, Integrator, Software Developer: Wolfram Manufacturing is a Triple Threat

Wolfram Manufacturing showcased its new facility, which houses its machine shop along with space for its work as a provider of its own machine monitoring software and as an integrator for Caron Engineering.

Read More4 Ways to Establish Machine Accuracy

Understanding all the things that contribute to a machine’s full potential accuracy will inform what to prioritize when fine-tuning the machine.

Read More