MMS Blog

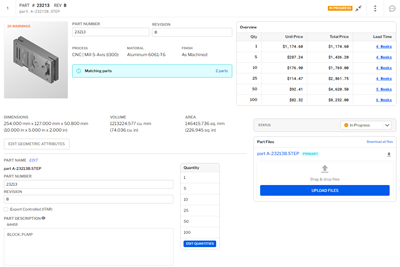

Give Job Shop Digitalization a Customer Focus

Implementing the integrated digital technologies and automation that enhance the customer's experience should be a priority for job shops and contract manufacturers.

Read MoreCNC-Related Features of Custom Macro

CNC-related features of custom macro are separated into two topics: system variables and user-defined G and M codes. This column explores both.

Read MoreModern Machine Shop Celebrates 95th Anniversary

Staying adaptable and leading through change for 95 years and counting, Modern Machine Shop celebrates its 95th Anniversary since its first publication in 1928.

Read MoreCombining Multiple Probes: A Recipe for Success

Combining measurement techniques enables a wide range of relational characteristics to be measured with just one or two sensors.

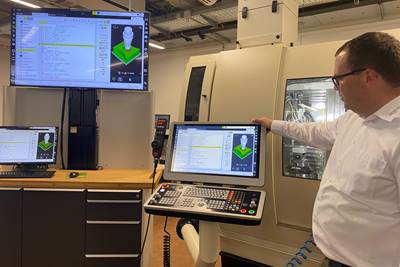

Read MoreManufacturing Technology and Training in Europe

NTMA’s European Tech Tour exposed attendees to the latest technology and traditional training methods used by European manufacturers.

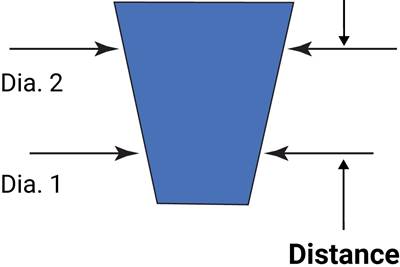

Read MoreThe Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

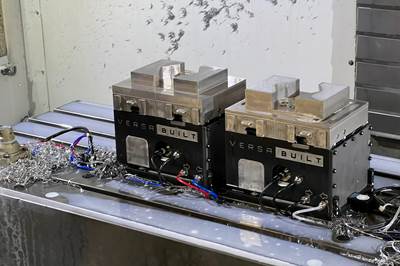

Read MoreUsing Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

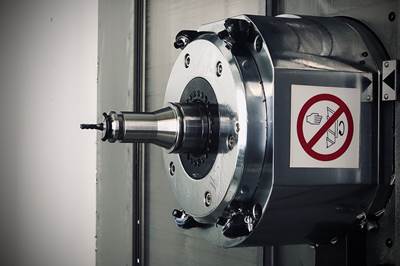

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

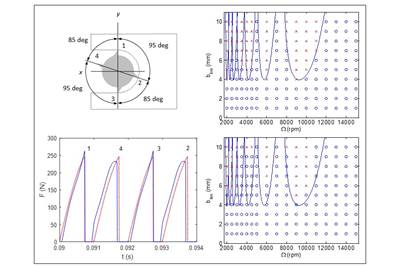

WatchHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Watch5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreHow to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

Read MoreHow this Screw Machine Shop makes Wooden Baseball Bats

Some people might call them batty, but this screw machine company has branched out into woodworking. Our sister publication Production Machining covers how W.H. Bagshaw purchased a wood lathe and began making custom baseball bats under the name Walter Bats, proving that you can't be afraid to swing for the fences on a new venture.

Read More

.png;maxWidth=300;quality=90)