MMS Blog

EDM, Laser Micromachining and More at GF Medical Demo Center

At GF’s Medical Center of Competence, the company shows off EDM and laser features that could make a large impact on medical manufacturing — and elsewhere.

Read MoreHow this Screw Machine Shop makes Wooden Baseball Bats

Some people might call them batty, but this screw machine company has branched out into woodworking. Our sister publication Production Machining covers how W.H. Bagshaw purchased a wood lathe and began making custom baseball bats under the name Walter Bats, proving that you can't be afraid to swing for the fences on a new venture.

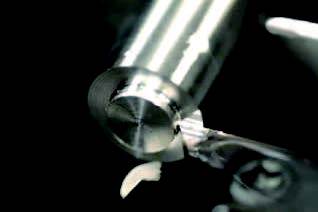

Read MoreToolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

WatchBecoming a More Efficient Shop With the Right Processes and Software

After refining its machining processes for more efficient production, this shop still needed a better way to track its data. Here's how it found a software solution.

Read MoreMost Metalworking GBI Components Contracted in May

Four components contracted slightly more than in April, including production, new orders, exports and backlogs.

Read MoreIf the Federal Government Is to Solve the Manufacturing Labor Shortage, it Needs to Start Here

Student-run businesses focused on technical training for the trades are taking root across the U.S. Can we — should we — leverage their regional successes into a nationwide platform?

Read MoreERP Captures Process Know-How Before it Retires

As shops struggle to overcome the skills gap, ERP systems can improve the onboarding process and help document processes as skilled workers retire.

Read MoreComputer Programming-Related Features of Custom Macro

Custom macro is an interpreter-based language, meaning that all CNC G code and custom macro commands are executed as the CNC comes across them.

Read MoreFor This Machine Shop, Licensing Is the Answer to the Inventor’s Dilemma

Machine shops are natural inventors, but not necessarily suited to supporting and marketing a product. This Minnesota shop with an invention related to micromolding will share it through licensing.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

WatchAutomation and Process Simplification Define Eastec 2023

Manufacturing technology at this year’s Eastec met the market with tools to streamline operations and assist machinists in achieving greater productivity.

WatchZoller Event Shines Lights on Shopfloor Connectivity

The company’s open house event highlighted smart manufacturing solutions from CAM to part.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)