MMS Blog

How to Pass the Job Interview as an Employer

Job interviews are a two-way street. Follow these tips to make a good impression on your potential future workforce.

Read MoreHow to Optimize Operator Efficiency on Any Shop Floor

Striking the perfect balance of person to machine is unique to each shop and can depend on a number of factors, including the type of work a shop undertakes, the available equipment, staffing levels, scheduling and more.

Read MoreMade in the USA - Season 2 Episode 3: The Robots Come Home

The latest episode “Made in the USA” podcast explores a company that uses collaborative robots, one of the key tools helping US machine shops and other manufacturers compete with lower cost countries by automating production.

ListenESOP Solidifies Culture of Continuous Improvement

Astro Machine Works’ ESOP rewards all employees when the shop does well, inspiring many toward continuous improvement as Astro expands its capabilities.

Read MoreDiving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

Read MoreBenchmarking: An Invaluable Business Tool

Modern Machine Shop’s Top Shops program shows shops their strengths and opportunities for improvement, and provides recognition for high-performing businesses.

Read MoreA Higbee Thread Milling Custom Macro

Higbee threads provide a full thread form at the very start of the thread. The sharp edge is removed during the machining process.

WatchCalling Home on a Portable Surface Gage

Today’s surface gages have a user interface that is just like a smartphone, and setting them up to make measurement requirements should be easy for the operator.

Read MoreAn American Manufacturing Story

For manufacturers that choose to move or keep production in the United States, what are the challenges and opportunities that motivate them?

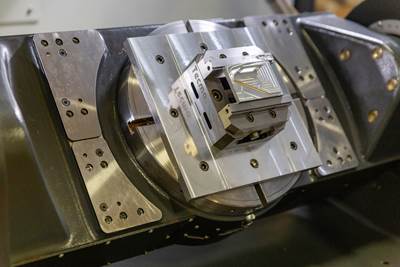

Read MoreRobots: Doing More With Less Floorspace

Robotic automation continues to grow more accessible to smaller manufacturers, as the floorspace necessary for these robots shrinks and their uses expand.

Read MoreMade in the USA - Season 2 Episode 2: Man, No Smoke!

When Puneet and Neelam Neotia moved from India to the United States several years ago, they brought with them a family background in manufacturing and CNC machining. Now the couple is working to get their startup machine shop off the ground, sourcing new customers and getting the word out about their shop in Clarksville, Indiana. The couple — proud to publicize their "Made in the USA" parts — is leveraging family connections and manufacturing capabilities back in India, but not in the way that some people assume.

ListenMetalworking Activity Contraction Slows Slightly in January

Most components held steady in January, but new orders and exports showed ever-so-slight slowing of contraction.

Read More