A Custom Tool Data Station Eliminates Machinists' Guesswork

An otherwise well-experienced team of machinists at Fab3R was nevertheless guessing when it came to insert choice and feeds and speeds. A custom cutting tool data station now provides instant retrieval of relevant tool data in one screen within arm’s reach of the tool vending machine.

Every day, Fab3R — a welding, machining and refurbishing company in Trois-Rivières, Quebec — manufactures large parts ranging from washer drums to turbine shafts. The machinists there are experienced, and they know how to do their jobs well.

However, when it came to choosing an insert grade, geometry, chipbreaker and cutting speed, they were guessing, says shop supervisor Simon Bellemare,

“I spent some time wondering why our good machinists would keep improvising their cutting speeds and feeds,” he says. The reason, it turned out, was not the lack of information but rather the difficulty of getting access to the exact information the machinists needed.

“Virtual things are good, but people like to see and touch the real thing. Combining a virtual catalog with a real display of the carbide inserts was the best thing we could do.”

“We have cutting tools from about 10 manufacturers and as many big catalogs,” Mr. Bellemare explains. “All those catalogs are different when you’re looking for cutting specs. Websites and apps like MachiningCloud help with the research, but you still need to search for the tool. Some machinists are discouraged when they face a 300-plus-page catalog, and some others are not comfortable with computers.” It’s not a matter of laziness, he says, but losing 15 minutes of productivity every time the machinist has to search for optimal cutting data is just not acceptable.

Mr. Bellemare wanted a way for machinists to effortlessly search for cutting specs every time. The goals in developing a new system were twofold:

- Machinists should be able to get the data they need in no more than one click.

- The information should appear in a single-page display.

One-Step Access to Cutting Specs

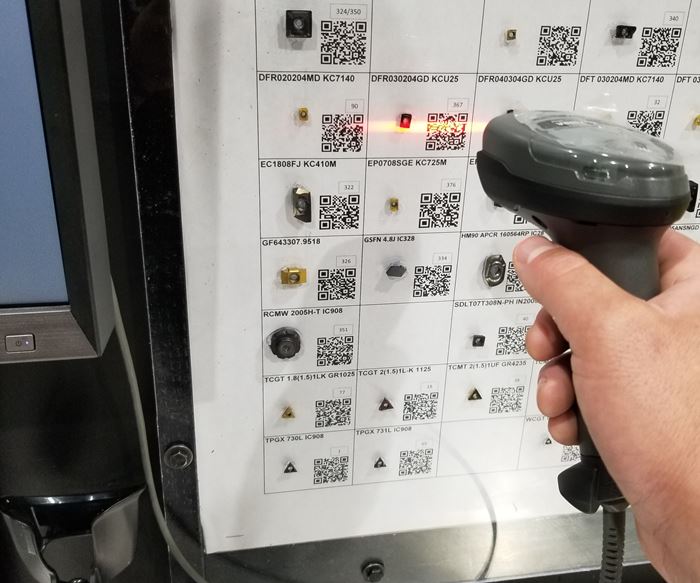

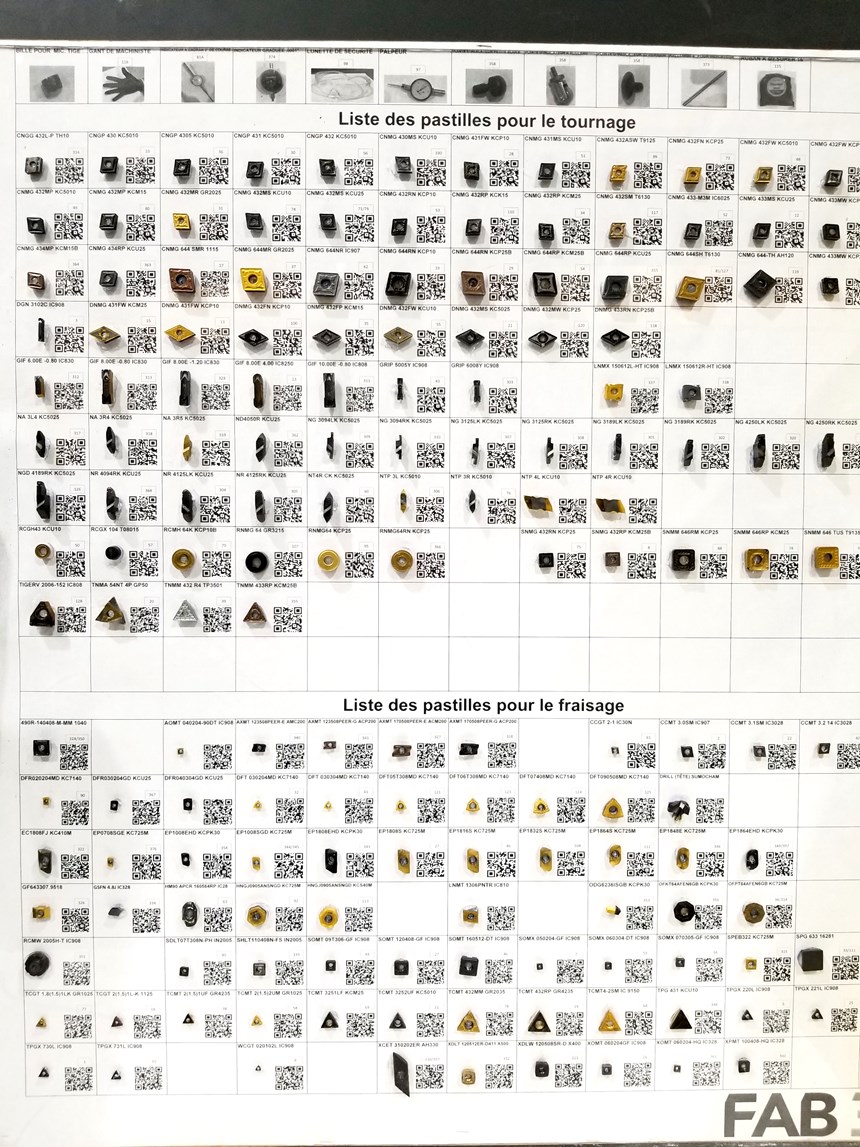

Eschewing a standard catalog, judging that most people would respond better to a visual format, “we opted for the real thing,” says Mr. Bellemare. This meant creating a display panel with a sample of each carbide insert glued onto it.

Next Fab3R needed a way to provide direct access to tool information. After considering a number of options — a push button, an NFC chip, a barcode — the team settled on posting scannable QR codes next to each insert sample. “QR codes are simple to create and to use,” Mr. Bellemare says. “As a bonus, they are free.”

A computer was installed next to the display board, having only one function: to read the QR codes. The app is the only thing allowed to run on the PC. “At any given time, we scan a code and we get the right page. Even those who had never touched a keyboard or a mouse can easily use it in seconds,” says Mr. Bellemare. That’s because the keyboard is not even necessary except for maintenance, since the machinist uses a handheld scanner to acquire the info from the QR code. Goal number one was thus achieved.

Condensing Cutting Data to One Page

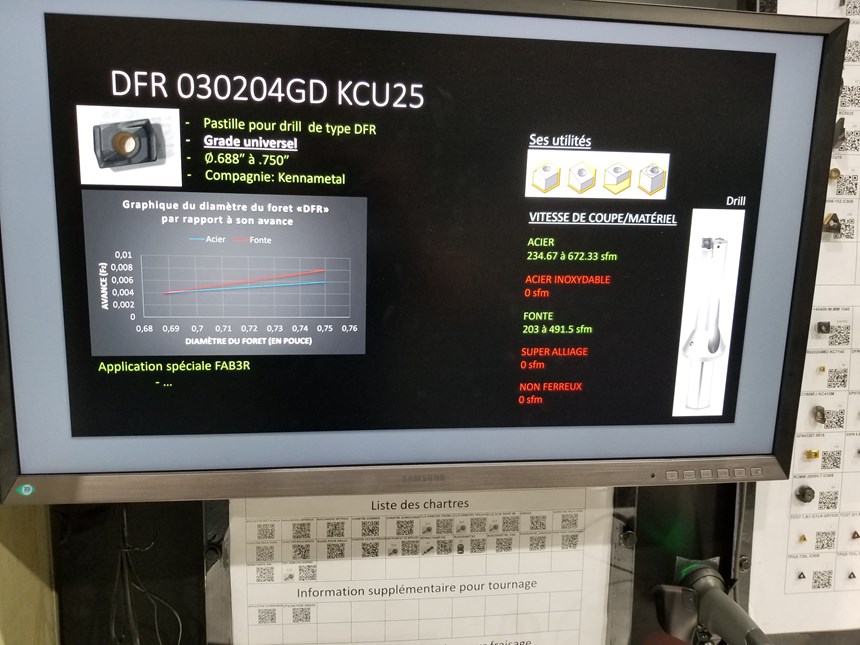

The next challenge was to get all the essential data displayed on a single page — no scrolling, no flipping. By “essential data,” Mr. Bellemare means only the information needed by Fab3R machinists.

“We don’t machine all the kinds of materials that exist, so we don’t need to show the cutting specs for those materials. It would only confuse the machinist and slow down research,” he says. So the team created their own cutting specs template. “We had an employee do the search for us in manufacturers’ catalogs and condense it in our template. We ended up with a very smart display with color codes and other visual cues.”

Another advantage of creating a template is standardization. Machinists face the same kind of display whether they are looking for specs on a carbide insert from Kennametal, Iscar, Tungaloy, Sandvik Coromant and so on. They don’t have to analyze different graphics, a new spreadsheet or various color code schemes. Goal number two achieved.

How the Tool Data Station Was Implemented

The tool information station has yielded the benefits of the two primary goals as well as others.

- The station gives the shop the ability to display Fab3R-specific applications. If, for example, a carbide insert performs well on a specific job, those cutting specs can be entered so that the next machinist who does the same job can easily start with the optimal speeds and feeds right from the start.

- Another QR code brings machinists to a page comparing chipbreaker and insert grades from different manufacturers. Like all the other entries, this one appears in the space of one page for ease of access.

- The station is located right next to the shop’s Kennametal ToolBoss vending machine. “From now on, no machinist should withdraw a carbide insert without knowing exactly how to use it,” Mr. Bellemare says. “Machinists will also have no excuses for choosing the wrong grade or chipbreaker.”

“I know we didn’t invent anything,” Mr. Bellemare concludes. “We just found a good use of an existing technology. Virtual things are good, but people like to see and touch the real thing. Combining a virtual catalog with a real display of the carbide inserts was the best thing we could do. The system works. Since the first day we installed it, people were scanning their chosen insert. It was so easy to use that everyone adhered to it.”

Related Content

Threading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

Read MoreBest Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

Read MoreA New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

Inventory: An Unseen Opportunity for Cutting Tool Cost Saving

Research finds cost saving is an expressed priority when it comes to cutting tools, but relatively few shops take steps aimed at reducing tool management’s contribution to overall cost.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)