A “Shortcut” for Bladed Components

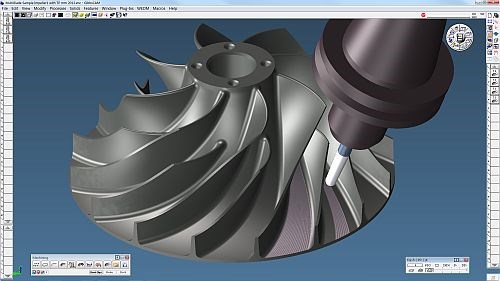

GibbsCAM offers two options designed to simplify the programming of bladed workpieces such as blisks and impellers.

Industries like aerospace and automotive depend on bladed components such as impellers and blisks, but these workpieces can be complex and time-consuming to program and machine. Gibbs and Associates’ MultiBlade options for GibbsCAM provide a simplified user interface optimized for working with bladed workpieces within the GibbsCAM environment.

Two levels are available, depending on the type of work or level of specialization required. Level 1 covers workpieces with single splitters, and Level 2 can be added to support multiple splitters, sub-splitters, blade fillet machining and other advanced features.

Watch the video above, produced by Gibbs and Associates, for an overview of the MultiBlade functionality in GibbsCAM.

Related Content

-

10 Things to Know About Creep-Feed Grinding

Because of the high material removal rate creep-feed grinding can deliver in challenging materials, grinding might not be just the last step in the process—it might be the process.

-

Beyond the Machines: How Quality Control Software Is Automating Measurement & Inspection

A high-precision shop producing medical and aerospace parts was about to lose its quality management system. When it found a replacement, it also found a partner that helped the shop bring a new level of automation to its inspection process.

-

Toolpath-Level Machine Monitoring Improves Aerospace OEE

Machine monitoring software that records historical efficiency to the toolpath level helped aerospace manufacturer Leesta improve its OEE by ten points.

.jpg;width=70;height=70;mode=crop)