Aligned for Precision

To precisely condition the form, shape and finish of an inside diameter of a workpiece, no machine tool outperforms an ID grinder if (and only if) key components of this grinder are properly aligned. This article outlines the importance of this alignment, explains how to recognize the symptoms of misalignment and describes what corrective steps to take.

To precisely condition the form, shape and finish of an inside diameter of a workpiece, no machine tool outperforms an ID grinder if (and only if) key components of this grinder are properly aligned. This article outlines the importance of this alignment, explains how to recognize the symptoms of misalignment and describes what corrective steps to take. The author, Bill Bednarski, is an applications engineer at Saint-Gobain Abrasives in Worcester, Massachusetts.

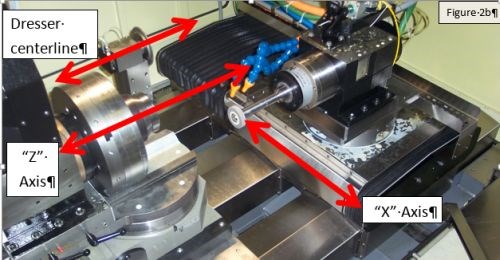

The components on a basic ID grinding machine that must always be in alignment are the X- and Z-axis slides, the grinding wheel spindle, the grinding wheel truing dressing device and the workhead spindle. As the linked article above shows, a properly aligned ID grinding machine, along with the right wheel specification and optimized grinding cycle parameters, will be a very cost-effective method to produce precision workpieces.

Related Content

-

Understanding Swiss-Type Machining

Once seen as a specialty machine tool, the CNC Swiss-type is increasingly being used in shops that are full of more conventional CNC machines. For the newcomer to Swiss-type machining, here is what the learning curve is like.

-

A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

-

7 CNC Parameters You Should Know

Parameters tell the CNC every little detail about the specific machine tool being used, and how all CNC features and functions are to be utilized.

.png;maxWidth=300;quality=90)