Alter the Axial Depth

In difficult-to-machine metals, when a pocket or similar deep feature is milled in successively deeper Z-axis levels, oxidation and chemical reaction can affect the tool at the upper surface level of each cut. The solution: Change the axial depth of cut for each pass.

In difficult-to-machine metals, when a pocket or similar deep feature is milled in successively deeper Z-axis levels, oxidation and chemical reaction can affect the tool at the upper surface level of each cut. Early damage to the tool can, therefore, occur at this one spot. The tool might have to be changed because of the wear at this one spot, even though the rest of the tool’s flute length is sharp.

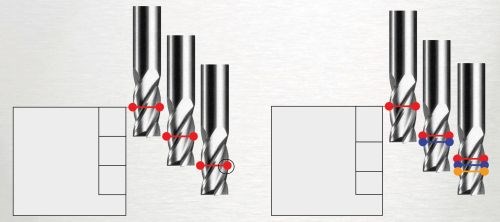

The solution: Change the axial depth of cut for each pass. This will distribute the problem area to different points along the tool, as the drawing above suggests.

This practical advice is one of 10 tips for machining titanium recently provided by cutting tool supplier Stellram.

Related Content

-

Ceratizit's Updated Tooling Solutions Improve Machining Performance

The company has upgraded its EcoCut indexable inserts lineup, as well as introduced two new toolholding and workholding solutions.

-

Grooving Attachment Streamlines Operation by 75%

A grooving attachment enabled Keselowski Advanced Manufacturing to reduce cycle times by over 45 minutes on a high-value, high-nickel part feature.

-

A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)