Black Swan Be-Ready Planning

Even the most nimble manufacturers with the most creative crisis management planning were likely caught flat footed by coronavirus—how can you better prepare for its remaining surprises and future crises?

As waves of the coronavirus ebb and flow throughout the U.S., it’s becoming increasingly clear that plastics processors who survive—or perhaps thrive—through the pandemic will be agile companies working from a living plan that they’re willing to change as the dynamic situation dictates.

Early on in the shutdown I spoke with Daron Gifford of Plante Moran about what restart would look like and what might be the new normal for production going forward. With many parts of the country hunkered down and the initial spike in cases and deaths seeming to plateau if not drop, Gifford’s words at the time seem prescient now as the U.S. sees a new uptick in virus activity that could threaten another complete shutdown in some states.

“It’s not likely that this will completely go away,” Gifford told me back in the early spring. “We don’t have a complete resolution to the coronavirus. There may be hot spots that pop up and could disrupt operations over the next 6 to 12 months.”

Gifford and Plante Moran were counseling manufacturers at the start of the crisis that there would be three phases they should prepare for:

- Respond—Manage through the crisis.

- Restart—Plan to reinitiate business operations.

- Plan—Build readiness for the next disruption.

Just since the turn of the century, the U.S. economy has been roiled by two major events that shook business, including manufacturing, to its core: 9/11 and the Great Recession. Back in the spring, Gifford saw that the breadth and depth of the coronavirus crisis made it an outlier. “This crisis, frankly, is dramatically different,” Gifford said. “Historically, the only thing that would really be close to this would be World War II, probably.”

“You can’t foresee everything—it’s impossible—but you need to have that capability in place; the decision processes that you can start to flex.”

The whole point of a so-called Black Swan event is that it precludes prediction—literally no one sees it coming. Epidemiologists have long worried about pandemics—that’s their job—but do the rest of us lose much sleep over them? Not so much, at least not before coronavirus. That’s what makes true out-of-blue-sky disasters so difficult.

“One of the challenges on disruptions is they don’t happen every year,” Gifford said. “That’s a good thing, but when they happen sporadically, your memory gets fuzzy. So a lot of the ‘be ready’ plans are pretty solid when we develop them, but then they get dusty. People don’t update them, or pay attention to them.”

A disaster plan can have a shelf date as the nature of threats—and technologies to deal with them—evolve. “The unfortunate part is that those plans probably don’t get the high priority they should, as far as the annual strategy type of look,” Gifford said. “The readiness plan is an ongoing, living plan that needs to be in place for the next disruption so you don’t get caught completely unawares.”

Mapping Out Your Supply Chain

Part of that advanced planning to boost preparedness ahead of what seem to be inevitable, ongoing interruptions from coronavirus will be mapping out your supply chain. Think not only about where you get your parts, but where the companies you get parts from, get their parts. The first time around, Gifford admits this process will require significant efforts, but subsequent updates will become easier thanks to that initial heavy lift.

“First, you have to map out all your current suppliers and products you’re buying from them,” Gifford said. “Then, you need to have a discussion with that supplier—if what you’re bringing is is a subassembly of some kind, who is their supplier and what’s their location.”

Gifford offers an example of just how convoluted a seemingly simple supply chain can become. “You talk to your supplier, and it might be someone who’s making a product in say Tennessee or Alabama or somewhere in the south, but when you dig deeper, they’re getting supply from Mexico or China or from another country, so now you’ve got to do a risk-evaluation process.”

Hope is not a plan, and all businesses are wise to think about their worst-case scenarios on a semi-regular basis, but even doing that can still leave you exposed, if less vulnerable.

“You can’t foresee everything—it’s impossible—but you need to have that capability in place; the decision processes that you can start to flex,” Gifford said.

Related Content

EDM, Laser Micromachining and More at GF Medical Demo Center

At GF’s Medical Center of Competence, the company shows off EDM and laser features that could make a large impact on medical manufacturing — and elsewhere.

Read MoreThe Producto Group Appoints New Member to Board of Directors

Dean Schauer, the newest appointee to the company’s board of directors, is the current CEO and president of Confluent Medical Technologies.

Read MoreFive-Axis Turnkey Machine Halves Medical Shop’s Cycle Times

Horizontal five-axis machines cut cycle times in half at ARCH Medical Solutions – Newtown. But its leadership gives equal credit to a surprising factor: the OEM’s service department.

Read MoreYCM Alliance Hits IMTS

YCM Technology has joined with other like-minded machine tool manufacturers to take a solutions-based approach to manufacturing.

Read MoreRead Next

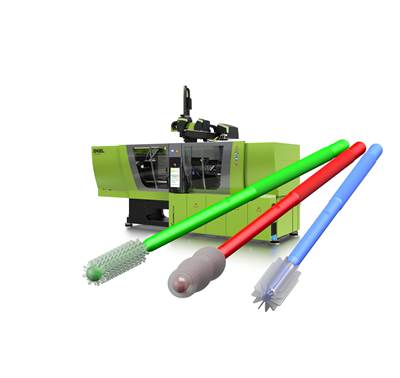

Covid-19 Test Swab Production Cell Introduced

Cell includes a mold, molding machine and robot with the ability to create 320 test swabs per minute and 460,000 test swabs per day.

Read MoreNPE2021: COVID-19 Update

PLASTICS addresses COVID-19 and NPE2021 and provides resources for the NPE community.

Read MoreCoronavirus and the U.S. Plastics Industry Supply Chain

While we cannot confirm today that the coronavirus has already impacted the U.S. plastics industry supply chain, it is reasonable to expect that if the coronavirus crisis in China continues and escalates, it will negatively impact the U.S. plastics industry. For business continuity reasons, U.S. plastics companies need to look at their current supply chain involving China and—as a precautionary measure—examine alternative supply sources.

Read More

.png;maxWidth=300;quality=90)