Buying a Coordinate Measuring Machine: Sorting through Standards and Probes

What’s the difference between the ASME B89.4.1 and ISO 10360 calibration standards for CMMs?

In the last post on the topic, we discussed coordinate measuring machines (CMMs) in context: how far they have come technologically, and where they are headed. Now, let’s take a look at a couple factors that make these systems so complex as well as capable: calibration standards and probe uses.

The Difference between ASME B89.4.1 and ISO 10360

Producing measurement data about a part to verify its accuracy and validate the integrity of its manufacturing process is a prime function of the CMM. However, to meet this function as well as to satisfy traceability requirements, CMMs must be properly calibrated periodically at a frequency set by the user. The two most common standards by which most CMMs are calibrated are ASME B89.4.1 and ISO 10360-2. The two standards are very similar.

The ASME B89 standard involves a ballbar artifact. Its use is generally confined to North America, whereas the ISO 10360 is favored in Europe, where it originated. This ISO standard is based on the measurement of certified length standards.

The B89 standard uses a ballbar of an uncalibrated length and is essentially a length measured repeatedly throughout the full working volume of the CMM. The axis scales are first calibrated by a separate test (linear displacement accuracy) using a calibrated artifact such as a step gage or laser interferometer. Once the axis scales have been adjusted to measure properly, the ballbar is then used to ensure that the measurement of this length parallel to any axis will repeat anywhere within the volume of the CMM. This ballbar test yields the maximum range of results from all measurements.

The ISO 10360 standard applies to articulated-arm CMMs using tactile probes and optionally optical distance sensors (also referred to as laser line scanners or laser line probes). It specifies the acceptance tests for verifying the performance of an articulated-arm CMM based on a calibrated test length as stated by the CMM manufacturer. It also specifies the tests that enable the user to periodically re-verify the performance of the CMM. Details on tests for scanner accessories are also given. Part of ISO 10360 specifies performance requirements that can be assigned by the manufacturer or the user of the articulated-arm CMM. It also specifies the manner of execution for the acceptance and reverification tests to demonstrate the stated requirements.

Which Probe and When?

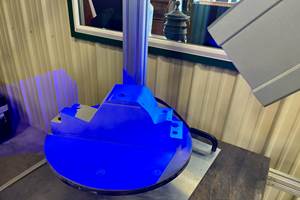

When inspecting parts with simple holes for which location and diameter are most important, a touch-trigger probe will be most appropriate for the job. Parts requiring form, best fit or true position calculations will require a scanning probe to capture adequate data for analysis. 3D scanning for modeling, reverse engineering or comparing to the CAD file are functions easily done on a CMM. Deciding which sensor to use is often determined by the required part accuracy and speed. If you’re manufacturing aerospace turbine blades, for example, five-axis scanners or 3D non-contact laser scanners will perform the work far more quickly and with less programming than touch-trigger probes. Fixed-head camera sensors, which are new to the market, are supposedly capable of scanning leading and trailing edges of turbine blades very quickly. When the profile of a surface or surface flatness is important, non-contact white-light and blue-light sensors or cameras can be used. There are also probes available to measure surface finish on a CMM.

CMMs add great value. In fact, producing data about a part to verify its accuracy, validate manufacturing processes, satisfy traceability requirements and serve other product lifecycle interests adds value as much as cutting chips does, so CMMs are, in fact, moneymakers—a good reason to select a new CMM with great care and forethought.

This is part two of a three-part series about buying a CMM.

- Part one: CMMs Past and Future

Find more insights about acquiring a new machine tool by visiting the Techspex Knowledge Center, “Guide to Buying Machine Tools.”

Related Content

Choosing the Correct Gage Type for Groove Inspection

Grooves play a critical functional role for seal rings and retainer rings, so good gaging practices are a must.

Read MoreA Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read MoreWhat Should Machinists Know About In-Machine Probing?

In-machine probing doesn’t reach the power of CMMs but can still be useful for pre- and mid-process control, as well as for “rough screening” of parts.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)