Cell Automates Multiple Part Change-Overs

An automated work cell on display in Okuma’s Booth S-8500 demonstrates not only robots loading and unloading parts, but also automated production run change-overs.

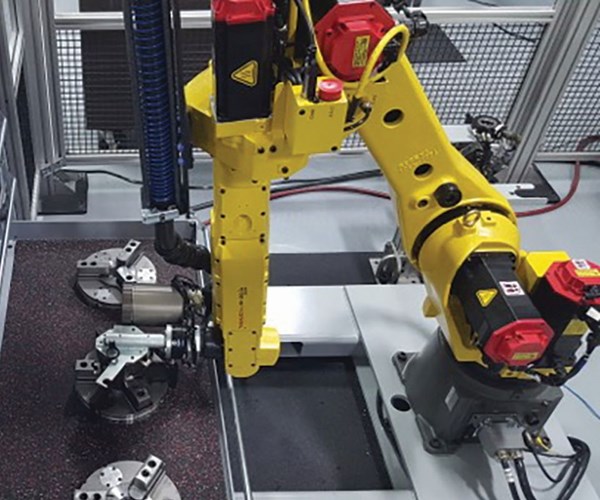

An automated work cell on display in Okuma’s Booth S-8500 demonstrates not only robots loading and unloading parts, but also automated production run change-overs. This means switching among a number of significantly different parts, not just members of a part family. In the cell, a Multus multitasking, CNC turning center performs a number of operations on a series of parts requiring three different three-jaw chuck face plates. A FANUC M-20iA industrial robot loads part blanks, unloads the finished parts and exchanges the chuck face plates as required.

Read the full story in the IMTS Show Daily.

Related Content

-

View From My Shop Video 1: A Deep Dive Into Automation with Advance CNC

Advance CNC leverages multiple forms of automation to increase its milling machines' productivity. Learn more in this episode of The View From My Shop.

-

Modern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

-

Zero-Adjustment Bar Pullers Simplify Turning Automation

Spring-loaded grippers and adjustable programming are enabling bar pullers to fulfill their promise to save time and money in CNC turning automation.