Centerless Sets the Tone for Shop-to-Stage Success

Grinding three shaft diameters at once eliminates runout and helps reintroduce a ‘70s-era guitar effects unit that mimics the action of a violin bow.

Guitarist Jimmy Page is renowned for using a violin bow to create droning, otherworldly tones on Led Zeppelin’s first album in 1969. Little did he know then that incorporating similar effects on the band’s last album 10 years later would not require a bow at all.

By then he had access to the Gizmotron, a mechanical bowing device invented by Kevin Godley and Laurence Neil “Lol” Creme of fellow British rock group 10cc. Played like a mini keyboard with the guitarist’s strumming hand, the Gizmotron contains a spinning, variable-speed aluminum shaft that drives spinning rollers into the strings, mimicking the infinite sustain of a violin or cello. Unfortunately for legions of amateur guitarists, the device ultimately proved too sensitive and difficult to use for broad commercial success. Now it is back, revived by a specialist in restoring keyboards who spent years tracking down original copies of the rare, notoriously fragile effects unit for his redesign efforts.

Even with years of experience recreating musical artifacts and a small team of engineers by his side, Aaron Kipness encountered significant difficulties in bringing Gizmotron 2.0 to market. The new design solved the problems of the old, but quality issues with the shaft created a tendency toward tone-distorting vibration. Producing the unit in any meaningful quantity required spending hours sorting through boxes of parts, singling out shafts that would both spin true and fit securely with bearings at either end.

The newly formed Gizmotron LLC went through three different machining vendors for the shaft before Mr. Kipness found Profile Grinding Inc., a 20,000-square-foot, 32-employee contract machine shop near Cleveland, Ohio. The shop guided its new customer through a few minor design changes that made the part suitable for centerless grinding, a finishing process that eliminated the vibration problem while keeping production cost-effective. “Not only did we provide a quality product; we did so at nearly 25 percent less than other quotes and delivered just in time for Christmas demand,” says Cory Homer, vice president of Profile Grinding. At the time of this writing, demand was expected to increase, and the shop was prepared to produce Gizmotron shafts at virtually any volume its new customer requires.

Where Centerless Shines

Profile Grinding was founded as a centerless grinding specialist by Mr. Homer’s great-grandfather in 1945, but grinding expertise is no longer the shop’s only asset. Approximately 60 percent of parts also move through milling, Swiss-type turning, or, most recently, multitasking mill-turn machines in advance of grinding.

This niche in complete machining of ground parts made the shop a good fit for Mr. Kipness and his team. Previous vendors machined the part complete on Swiss-types, but turning was not enough by itself to ensure the shaft would spin true at speeds ranging to 5,000 rpm. The third vendor recognized the need for additional finishing to maintain ±0.0002 inch runout, but it did not offer that service. Profile Grinding offered a single source for not only turning the part, but for doing so with an eye toward the critical finish- grinding process.

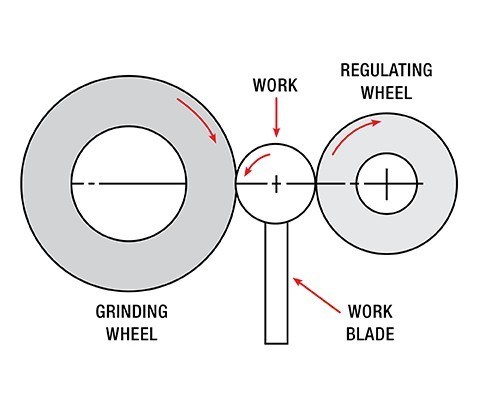

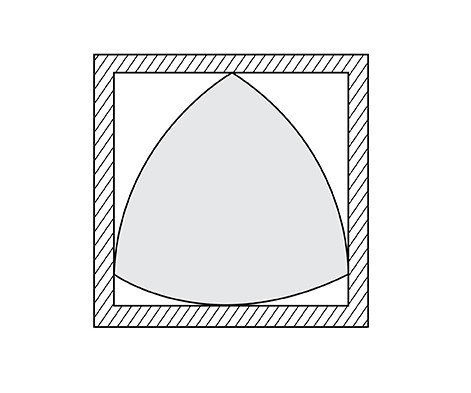

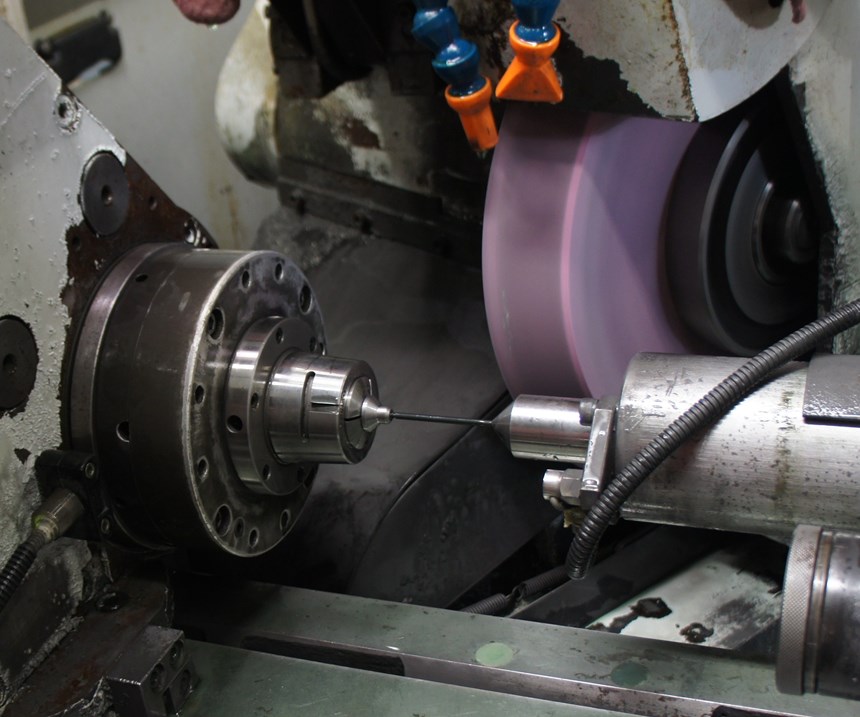

Preparing the Gizmotron shaft for grinding required ensuring that initial turning of the shaft’s profile (an operation conducted on an L20 Type IX Swiss-type lathe from Marubeni-Citizen Cincom) leave 0.005 inch of extra material on the main diameter. The shaft was then placed on a work-support blade between the grinding and regulating wheels of a Cincinnati Milacron Cinco 15, an NC-controlled centerless grinding machine with CNC dresser. The extra stock left by the turning operation ensured that the grinding wheel, wide enough to cover the entirety of the shaft and dressed to the mirror shape of its profile, engaged the longest section before bringing the smaller ODs into contact with the aluminum oxide grinding wheel. This practice ensured stability as the part began to spin, driven axially against a workstop by the action of the slightly tapered regulating wheel and the main grinding wheel. “When you bring (all diameters) into tolerance at the same time, runout will be nearly perfect,” Mr. Homer says.

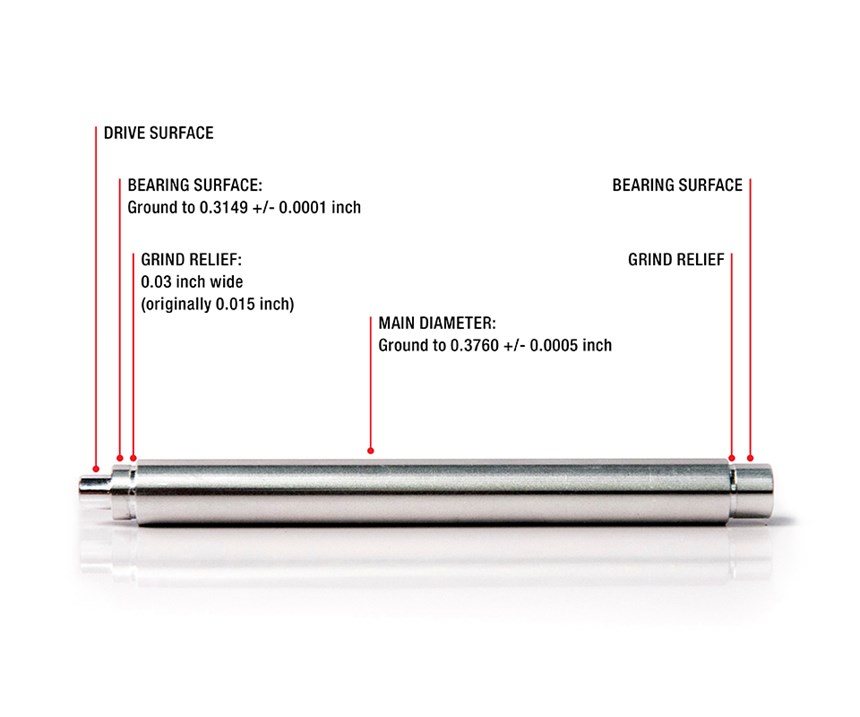

With runout eliminated, the wheel was redressed to a smoother grain for a finish-grind that achieved final size and surface finish specifications (0.376 ±0.0005 inch for the main diameter and 0.3149 ± 0.0001 inch for the bearing surfaces with a 32-Rms Finish). He says the same results could be achieved by grinding the part between centers. However, high-length-to-diameter-ratio parts like the Gizmotron shaft generally process more efficiently on a centerless machine. Precisely setting the height of the support blade requires knowledge and skill, but this task is less complicated than working with dedicated fixturing devices, even including simple dead centers paired with a “drive dog” clamp that transfers spindle motion to the workpiece. And in this application, grinding the smaller end sections of the shaft without a collision between wheel and fixture would have required flipping and re-clamping the part. All told, Mr. Homer says the complexity of grinding between centers would have made the operation cost at least twice as much as centerless grinding, possibly even three times more.

Landing the Work

Although grinding between centers would have been more complicated and more expensive, it appeared to be the only option at first, Mr. Homer says. Initial plans for the Gizmotron 2.0’s shaft had the end diameters terminating too close to the main diameter. “You can’t grind up a shoulder,” he explains.

Contoured grinding wheels—and by extension, ground features—can be only as precise as the dressing tool allows, he continues, and there is a tolerance to everything. In this case, the 0.02-inch-radius edge of the diamond dressing tool was not capable of creating a corner as sharp as the turning machine. Any rounding in the profile of the wheel would translate directly to the profile of the shaft. Avoiding this effect required longer reliefs—longer undercuts immediately adjacent to the main diameter to ensure the rounded portions of the wheel encountered only air. With this additional empty space between sections of the shaft, grinding could proceed on all three critical diameters without fear of the wheel rolling material over the sharp-cornered shoulders created by the turning machine.

Having experienced problems with bearings popping off shafts produced by other suppliers, Mr. Kipness was initially wary of any change that would reduce the size of the bearing lands. However, previous experience with similar parts made the shop’s staff confident that doubling the width of the relief between diameters from 0.015 to 0.030 inch would not cause problems. Given the Christmastime success of the product and the anticipation of future orders, Mr. Kipness’ trust in his new supplier paid off. Assembly time improved, and worries about scrapping expensive bearings due to bad shafts became a thing of the past.

For Profile Grinding, this job was a relatively simple one, even compared to some of the roughly 40 percent of jobs that involve no machining other than grinding. Nonetheless, it demonstrates that for customers like Gizmotron LLC, capability to handle and help plan the entire manufacturing sequence makes the shop a particularly good partner, says Meg Grant, communications manager. “We understand what blanks need to look like to achieve a certain grinding output,” she explains. “That enables us to anticipate problems and provide the most economic means of production without sacrificing fit and function.”

Related Content

How to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAM system. Here’s how the company succeeded, despite the newness of it all.

Read MoreThreading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

Read MoreInside an Amish-Owned Family Machine Shop

Modern Machine Shop took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

Read MoreBuying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More