Centerline Issues for Turning Inserts

Tooling experts Mike Fagan and David Grant suspect that many programmers and machinists could use a refresher on the importance and effects of insert alignment in turning operations. This short, amply-illustrated paper is their effort to clear up some of the misunderstanding.

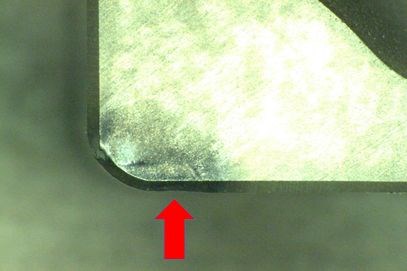

Photos of sample inserts such as this one illustrate wear patterns that help diagnose cutting tool misalignments in turning.

Tooling expert Mike Fagan suspects that many programmers and machinists could use a refresher on the importance and effects of insert alignment in turning operations. This short, amply-illustrated paper is his effort to clear up some of the misunderstanding.

It covers signs of misalignment and suggests ways to fix problems, with additional tips and advice to improve turning operations. To find the paper, click here.

Related Content

-

Best Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

-

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

-

How to Turn Machine Shop Downtime Into Process Expertise

To take advantage of a lull in business, JR Machine devised a week-long cutting tool event that elevated the shop’s capabilities with aerospace alloys.

.png;maxWidth=300;quality=90)