Cool Tricks: How to Photograph Sinker EDM

Sometimes it takes a little extra effort and ingenuity to solve a problem. In the case of the February 2020 cover of Modern Machine Shop, it took a lot of each — and a cheap plastic spaghetti container.

Sometimes you need both the picture and a thousand words. Or, in the case of our cover photo for the February issue of Modern Machine Shop, that and 497 words here at the very least.

Shortly after I finished the article Inside the Sinker EDM Process, One Spark at a Time,” I reached back out to its main source, Pat Crownhart, in the hope that he might be able to provide a visual depiction of the electrical discharge machining (EDM) process that it discussed. The central point Mr. Crownhart made in the article was that, despite the rapid discharge of sparks during the EDM process — up to 30,000 per second — these sparks are produced one at a time. This is critical information if one is to control the subtle but important electromechanical dynamics at play during the sinker EDM process.

Mr. Crownhart, MC Machinery System’s sinker EDM product manager, responded that he did not have any such photos at hand, but would try to put something together. What happened next was one of the most clever uses of food storage I’ve ever seen.

Mr. Crownhart reached out to colleague Adam Wysuph, a sinker EDM application engineer with MC Machinery for the last 15 years, to suggest a plan.

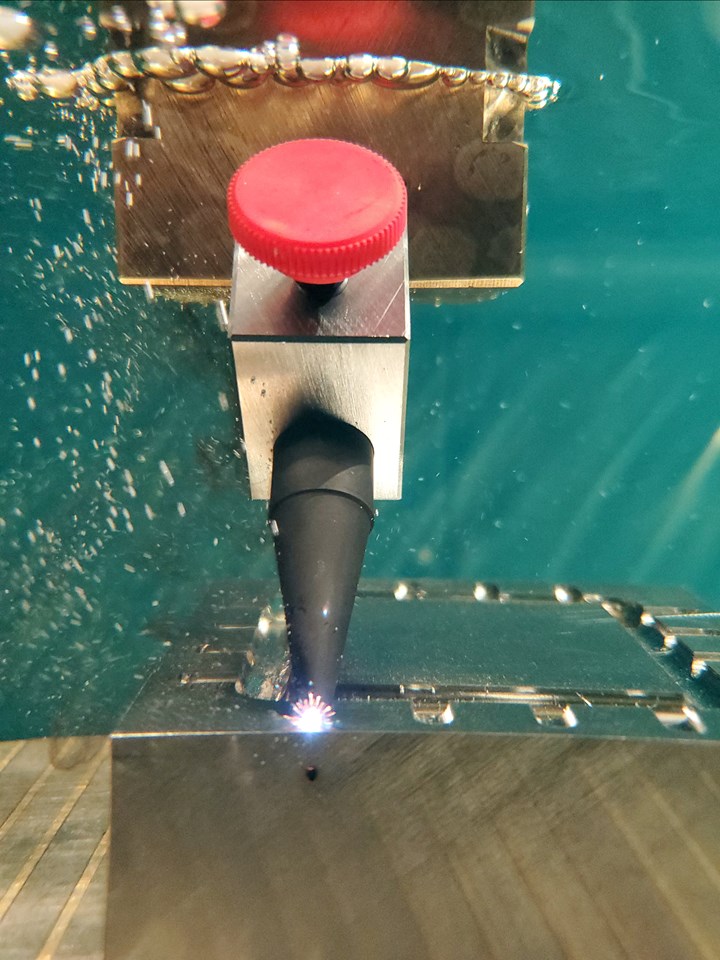

Here is a Mitsubishi Electric SV12P cutting tunnel gates into H13 steel. Photo: Adam Wysuph.

Since there’s no better way to visually depict the sinker EDM process than by literally sinking a camera into the dielectric, Mr. Wysuph dropped in his GoPro and fired off several shots. The images were interesting — on the right track for sure — but hazy. The resolution was too low to capture the sparks flying off of the part.

Time for plan B: Find another, higher resolution camera, concoct a way to keep it dry while immersed in dielectric fluid, and remotely trigger several photographs.

Here’s how Mr. Wysuph produced an image that made the cover of Modern Machine Shop:

Step 1: Traveled to The Container Store and purchased a $10 airtight, clear plastic spaghetti container.

Step 2: Placed his new Samsung smartphone inside the spaghetti container, along with a 4- by 4- by 2-inch block of H13 tool steel to serve as ballast.

Step 3: Dropped the container into the dielectric of a Mitsubishi Electric SV12P and positioned it near (but not too near) the electrode.

Step 4: Began an EDM operation on a demonstration part — in this case, machining a tunnel gate into H13 steel for a plastic mold.

Step 5: Used the Samsung’s stylus to trigger several photographs.

Step 6: Sent the images to me, who shared them with my colleagues, who decided to use one of them for the February 2020 cover.

Voilà.

Mr. Wysuph captured this photo remotely using his smartphone’s stylus as a trigger.

We would like to thank Mr. Wysuph and Mr. Crownhart for their ingenuity and efforts.

Related Content

-

When Organic Growth in Your Machine Shop Isn’t Enough

Princeton Tool wanted to expand its portfolio, increase its West Coast presence, and become a stronger overall supplier. To accomplish all three goals at once, acquiring another machine shop became its best option.

-

Watchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

-

Choosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)