Corner Concerns

Little things mean a lot.

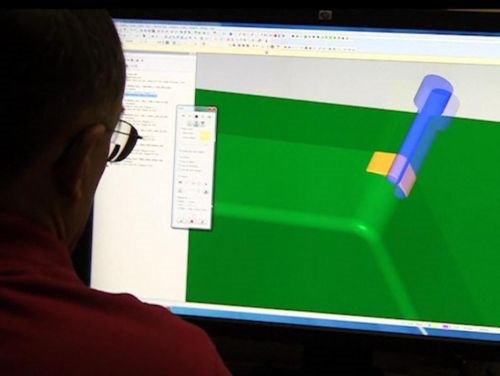

Little things mean a lot. The corners might seem like a relatively small part of a pocket, but machining corners is actually one of the most challenging operations for the cutting tool to perform. The latest video from MMS Online video contributor Todd Schuett focuses on milling pockets in hard steel workpieces, paying particular attention to how to mill the corners of these pockets effectively.

There are actually a variety of corner-milling strategies that shops have tried and embraced. A leading cutting tool maker advocates a toolpath technique called “slicing,” described here. An aerospace shop routinely mills at full cutter width, just so the depth of cut won’t change when the cutter does enter a corner. Read about that commitment here (scroll down to the sidebar). In addition, an alternative algorithm for tool paths dramatically increases tool performance in hard materials in part simply by avoiding cornering moves. The effectiveness of that algorithm can be seen (and heard) in this video.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)