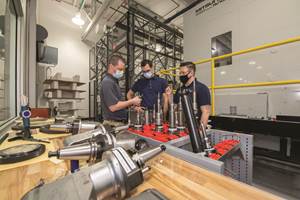

IPG President Dave Cox and Vice President of Business Development Matt Cox are shifting the company away from a job shop business model to become an aerospace supplier, grinding parts like this helicopter main shaft. This move has required changes within the company, including new equipment, AS9100 certification and a marketing plan.

Indiana Precision Grinding (IPG) is no stranger to making business changes. William Cox founded the company in Indianapolis in 1975 as the Centerless Grinding Co., but when he realized the volume of local centerless grinding work wouldn’t support the business, he expanded its capabilities to include other grinding services, such as cylindrical grinding. In the mid-1980s, the company moved and rebranded as IPG to reflect these changes.

IPG is in the middle of another shift, this time from a job shop business model that serves a diverse local customer base to one that specializes in aerospace work. This was a difficult decision for IPG to make, and has required new equipment, an AS9100-certified quality management system (QMS) and a marketing plan. But the company’s president says recent changes in the manufacturing industry have made this shift necessary even in spite of recent turbulence in the aerospace sector, and it is proving successful so far.

Finding a Niche

When William Cox passed away in 1999, his son Dave took over as president. Around this time, Dave started to notice a shift in the manufacturing industry. IPG’s customer base was local job shops, but as local companies were moving, closing and being bought, this base was shrinking. “Within a three-mile radius, in the last 20 years, there's been companies that have gone out of business that total over 100,000 jobs,” he says. These shops weren’t necessarily IPG’s customers, but Dave knew the company wouldn’t grow supporting this market. He wanted to open IPG to other geographical markets, and to do that, it needed to take on specialized work. “If you're doing low-value parts, someone doesn't want to ship it from Connecticut to Indiana. But when you're doing high-value parts, the shipping cost becomes minimal,” he explains. As he considered the industry landscape, he saw opportunities in the aerospace industry.

Since starting this shift, IPG has found a niche: grinding parts with thermally applied coatings. As companies push to reduce aircraft weight, they’re replacing chrome-plated landing gear components with titanium parts that have thermally applied coatings, such as high-velocity oxy-fuel (HVOF) tungsten carbide coating.

IPG got its first high-volume part of this type six years ago: an axle sleeve for

IPG has developed a niche in the aerospace market: grinding parts with thermally applied coatings. This Positrol workholding fixture brings aircraft axle sleeves into round so the thermally applied coatings can be ground evenly.

an Airbus aircraft with a thermally applied coating on the ID and OD. When IPG received the machined parts from its customer Goodrich (now part of Collins Aerospace), they were 0.010 inch out of round, making them difficult to grind evenly. This was an issue because if the axle sleeve doesn’t have an equal coating thickness all the way around, it doesn’t perform as intended.

The company worked with Positrol to create workholding fixtures that bring the part into round for grinding. First, IPG uses a fixture that expands out from the ID and brings the part into round to grind the substrate OD. Then the part is sent out for OD coating. Back at IPG, it’s put on the same workholding fixture to grind the OD coating. After the IDs are coated, it’s put on another workholding fixture that holds the ODs while the ID coating is ground. “Now our ODs and IDs are within one thousandths true position of each other, ID to ID and IDs to ODs. And we maintained the wall thickness,” Dave Cox says. IPG is now producing 130 of these parts per month.

Equipment

IPG developed the process for the axle sleeve on a 1940s-era Springfield vertical grinding machine, but as work ramped up, it needed new equipment. “We had been asked to quote several parts that were outside of our machine capacity, and we decided if we were going to continue to move forward in the aerospace industry we need to be set up to do parts that were that size range,” Dave Cox says. Five years ago, the company purchased a Taiyo Koki Vertical Mate from DMG MORI that can handle parts as large as 32 inches in diameter. This dramatically increased IPG’s capabilities, as it could previously only handle parts that were 16 inches in diameter. Additionally, the new machine’s vertical platform aids in loading and grinding parts that are heavier and have larger diameters. The machine has been so successful that IPG added a smaller Vertical Mate a year ago.

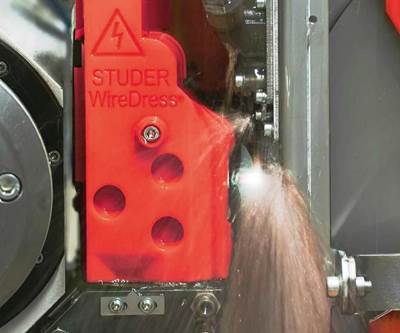

The company also purchased a Studer S33 cylindrical grinder with an automatic quill changer that allows six different wheel configurations in its toolchanger. The toolchanger can hold superabrasive grinding wheels for grinding surfaces with thermally applied coatings, as well as wheels for grinding substrates and form grinding wheels. This enables IPG to grind parts with coated and non-coated surfaces in a single process, or parts with features that require form and traditional grinding.

AS9100 Certification

In addition to new equipment, IPG has added AS9100 certification. This was one of the first steps the shop took in the early 2000s, but it continues to affect the shop as revisions are made. Dave Cox says the additional requirements of an AS9100 quality management system (QMS) can be a challenge for smaller companies like IPG, but a recent audit changed his perspective. He was trying to work with the auditor to remove the requirement that the company send its gage blocks out for calibration because IPG doesn’t do purchasing — it works with its customers’ parts. “The guy turned around and he looked at me. He goes, ‘Look man, you're not a job shop. You're not a grinding shop. You are an aerospace company. And you need to think like that in every element that you have,’” Dave Cox says.

“‘...you're not a job shop. You're not a grinding shop. You are an aerospace company. And you need to think with that in every element that you have.’”

The latest revision, Rev D, which focuses on risk management, has helped IPG manage risk for both its customers and its own business. Dave Cox developed a form that the company’s vice president of business development, Matt Cox, uses when quoting new jobs. It rates the risk of a job on a scale of one to three. One is a part they’ve done before, two is a part similar to one they’ve done before and three is an entirely new part. If IPG determines a job to be high risk, the team meets to try to mitigate it. The shop also shares this information with customers and collaborates with them to minimize potential problems. For example, the customer could provide workholding or an inspection technique. If the shop and customer can’t find a way to reduce the risk, IPG will take itself out of the running for that job.

When evaluating the risk of a new job, the shop considers many factors, including:

- Machinist skill levels. What skill level will the job require? Are machinists of that skill level available? If not, can the shop use other machinists and mitigate the risk by pairing them with an engineer or inspector?

- Volume. Just because a job is simple doesn’t mean IPG should take it. Matt Cox says that he recently received an RFQ to grind 2,000 bars. “We're not set up to compete with material houses or bar grinding shops,” he explains. “The grind process and the tolerancing was very low risk. That’s a one. We can do that in our sleep. The volume makes it a three because it's going to put a strain on us.”

- Capabilities. This involves more than just part dimensions. Matt Cox says he once quoted and won a job that technically fit IPG’s capabilities. “The part got in here, and it weighed too much,” he says. “It was going be very dangerous to try to load it. Our hoist would not hold it. But I had nothing to tell me that.” Now the shop takes additional factors, including part weight, into account.

As IPG started quoting more aerospace jobs, Dave Cox realized the shop was going to need larger machines. It purchased a Taiyo Koki Vertical Mate that increased the maximum size of the parts it could handle from 16 inches in diameter to 32 inches in diameter.

Matt Cox also uses this information for business development. For example, if a high-risk job is recurring, IPG could consider investing in new equipment. “It's just not for protecting the work we do and our quality. It is also the other side, opening the doors for our business, to ask more questions and be better prepared,” he says.

In the end, Dave Cox says that implementing an AS9100 QMS will prove to have helped instead of hurt the shop’s profitability. “We didn't have training plans in place. We didn't have maintenance plans in place. We weren't even calibrating our gages. None of that was in place,” he says. “There’s a bunch of costs associated with that, and a bunch of costs to get all those things into play. But as soon as that happened, problems started going away.” In the end, AS9100 made IPG more process-oriented in a way that benefited the shop instead of burdening it.

Marketing

The most recent step IPG has taken on its journey to become an aerospace supplier is implementing a new marketing plan. Prior to this, IPG mostly operated on existing relationships and word of mouth. “We had no one who worked for us in sales, and we did zero marketing,” Dave Cox says. But as it transitioned to becoming an aerospace supplier, it needed a way to reach a very specific set of companies across the country. “We are a niche. Not everyone's going to need us,” he explains. “But the people who do, where are they and how can we get in front of them?”

“We are a niche. Not everyone's going to need us. But the people who do, where are they and how can we get in front of them?”

IPG partnered with marketing company Sharp-Wilkinson, which crafted a marketing strategy that targets the market IPG is pursuing. It starts with creating semi-fictionalized representations of who IPG wants do business with — the decision makers on aerospace buying teams. The company then designs content that will appeal to these people and distributes it to places they’ll find it. IPG’s website serves as a hub for the content, as well as a forum to show its expertise. The goal is to drive traffic to the website. Once there, visitors can go down a number of conversion paths. And because aerospace projects are planned far in advance, IPG must stay in front of its audience until the time is right.

According to Sharp-Wilkinson’s co-owner Jack Wilkinson, this approach is

IPG’s Studer grinding machine can hold six different wheel configurations in its toolchanger, enabling it to grind substrates and thermally applied coatings or parts with form and traditional grinding in a single process.

driven by data and provides a measurable ROI. “We identify numbers that have to move in the right direction for you to get that revenue at the end. And then we monitor those numbers. And if any of those metrics fail, we know we have to optimize that part of the process,” he says. The numbers start with sessions on the website, then move to conversions, leads and eventually, sales.

IPG and Sharp-Wilkinson are still in the early stages of their partnership, working on deploying content and increasing sessions on IPG’s website. Currently, aerospace makes up 70% of IPG’s work, and 25% of its sales are from outside the region, but the two companies are hoping to increase both of these numbers.

IPG’s commitment to the aerospace industry recently faced a test, as the COVID-19 pandemic disrupted the commercial aerospace market. However, the company remains as committed as ever to its strategy. Dave and Matt Cox report a small decline in commercial aerospace work but say that defense work (which is considered essential) is as strong as ever. IPG has also used this time to examine its client base, onboard several new employees and add nital etch inspection capabilities. “When the pause is lifted, IPG wants to be right in there to support all of our current and future customers with their needs,” Matt Cox says.

Related Content

When a Lathe With Live Tooling Rivals a Multitasking Machine

This shop is working its way up to a full-fledged B-axis multitasking machine. Meanwhile, turning centers with a Y-axis and live tooling are doing just fine.

Read MoreDigital Twins Give CNC Machining a Head Start

Model-based manufacturing and the digital thread enable Sikorsky to reduce lead times by machining helicopter components before designs are finalized.

Read MoreMachine Monitoring Boosts Aerospace Manufacturer's Utilization

Once it had a bird’s eye view of various data points across its shops, this aerospace manufacturer raised its utilization by 27% in nine months.

Read MoreBeyond the Machines: How Quality Control Software Is Automating Measurement & Inspection

A high-precision shop producing medical and aerospace parts was about to lose its quality management system. When it found a replacement, it also found a partner that helped the shop bring a new level of automation to its inspection process.

Read MoreRead Next

Swiss Grinding Technology in Motion

During a recent open house at Studer’s headquarters in Switzerland, the company highlighted advances in cylindrical grinding technology including automation solutions to enable long stretches of unattended operation.

Read MoreMultitasking Forms Hub of Shop’s Propeller Production Efficiency

Outsourcing machining for complex hub assemblies resulted in months-long lead times and lack of control. A Mazak multitasking machine allowed Whirlwind Propellers to bring production in house.

Read MoreDeveloping a Five-Axis Solution for Machining Superalloy Aerospace Parts

Growing involvement in producing multi-blade aerospace parts made of superalloys presented Pietro Rosa with some machining challenges. Starrag’s LX 021 five-axis VMC helped the shop achieve tight tolerances and integrated production.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)