Emag Emphasizes Modular Gear Making

A recent open house event showcased an approach to tailoring a gear production system not through custom engineering, but by assembling the line from complementary standard machines.

The VL 2 and VL 2 P are vertical pickup turning machines that could be incorporated into a modular gear-making line. Hobbing and deburring/chamfering machines with the same footprint could be linked to these machines via automation.

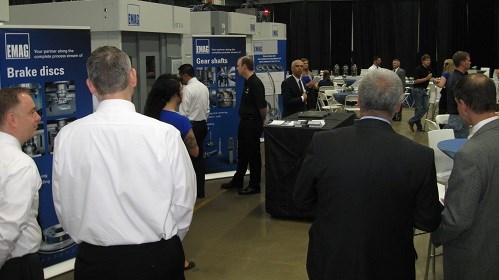

For Emag USA, this is an anniversary year. The Farmington Hills, Michigan, branch of the German machine tool maker was established 20 years ago. The company is known for customized gear machining systems, as well as for inverted vertical lathes for high-volume production in the automotive sector. At the company’s “Technology Days” event last week, presenters described how the company is building on and expanding beyond its success in these areas.

In gear making, engineering machines to customer applications remains an important part of the company’s business, but a lower-cost option that customers are increasingly choosing is to build a gear-making line out of standard modules. Small-footprint standard machines can be linked together through automation to perform a series of gear machining operations. For example, four standard machine modules for an op-10 through op-40 line could perform (1) first side turning, (2) second side turning, (3) hobbing and (4) deburring and chamfering.

In that sequence, Emag Koepfer machines would perform steps 3 and 4. Gear machine maker Koepfer was acquired nearly 10 years ago, and this line’s offerings now include modules designed to be similar and complementary to Emag lathes. A more recent acquisition, Eldec, supplies hardening equipment—suggesting that this capability will eventually be offered in a complementary module as well.

The modular approach of creating a custom line by assembling it entirely from standard machines saves cost and simplifies maintenance, Emag says. Yet another advantage is the high throughput that results from having multiple machines processing multiple workpieces simultaneously. Emag offers part-handling automation for linking these machines.

Also at the Technology Days event, another presentation described a new turning machine soon to be available. The company’s VM machine will be a non-inverted vertical lathe. That is, the machine is a vertical lathe with the spindle under the workpiece, a configuration that might be typical for vertical lathes in general, but represents a new expansion of the turning line for Emag. The machine will be available in the U.S. in about 3 months, the company says. The expectation is that it will expand the company’s activity with manufacturers outside of the automotive sector. Many aerospace parts, for example, feature thin walls that would preclude being clamped by an inverted vertical machine, though the same parts could be processed efficiently using a spindle-down vertical having the same small footprint as Emag’s established production-oriented turning machines.

Demonstrations and presentations at the recent Emag USA event covered gear making and production turning, as well as electrochemical machining, integration of turning and grinding, and machining brake discs and CV joints.

Related Content

-

How to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAM system. Here’s how the company succeeded, despite the newness of it all.

-

Digital Twins Give CNC Machining a Head Start

Model-based manufacturing and the digital thread enable Sikorsky to reduce lead times by machining helicopter components before designs are finalized.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)