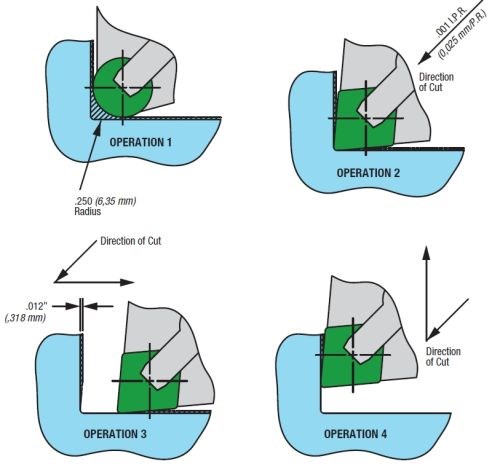

Finishing Fillets

Consider these finish-machining techniques that can enable you to maximize material removal rates prior to completing accurate, tight-radii fillets.

Here’s one method of finishing a fillet using an 80-degree insert.

Just because a pocket calls for a fillet with a tight radius doesn’t mean the entire thing should be rough-machined with a tool having that radius. As cutting tool manufacturer Greenleaf explains, radii like these typically are small. Therefore, a tool having such a radius is generally weak and must be indexed or changed numerous times if the plan is to use it to complete the entire operation. However, there are a number of effective methods available to finish fillet radii after performing roughing operations using a different, more appropriate tool. The company highlights four of them here.

Related Content

-

A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

-

Twin Spindle Design Doubles Production of Small Parts

After experiencing process stalls in the finishing stage of production, Bryan Machine Service designed an air-powered twin spindle and indexable rotating base to effectively double its production of small parts.

-

All-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)