Five-Axis Conversational Programming from a Solid Model

This CNC feature imports a 3D solid model from which operators can perform conversational-type programming even for five-sided machining applications.

CNC conversational programming software enables machine tool operators to create part programs directly at a machine’s control by answering prompts for information that defines the part and the requisite operations to complete it. The control then automatically creates the NC program in the background. G-code knowledge and what can be time-consuming line-by-line programming are unnecessary.

In the past, this type of programming was used for relatively simple part geometries, or for programming parts defined only in 2D prints. Increasingly though, design engineers are able to supply shops with 3D solid models of the parts they need to be machined. Mike Cope, product technical specialist for machine tool builder Hurco, says as a result, its customers have been asking for a means to create part programs conversationally directly from customer-supplied solid models. This is now possible using the 3D Import option on Hurco’s WinMax CNC for three-axis work or five-sided machining.

It is now possible to create part programs conversationally directly from customer-supplied solid models.

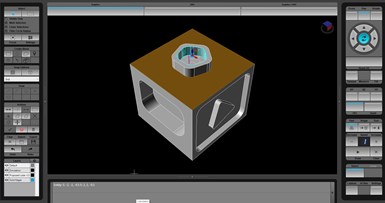

Once a model (.stp file) is imported, it can be oriented on the control screen to view specific features to be machined.

Users can position solid models to view the features to be machined. For a pocket, the user would select its floor and top, and the depth is automatically pulled from the model.

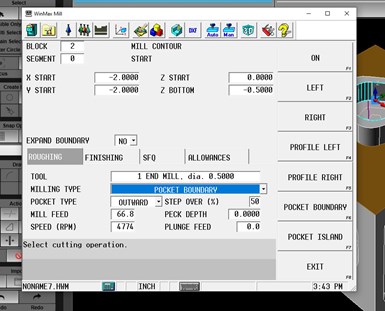

Take a pocket as an example. A user selects the floor of the pocket, then identifies the top of the pocket. The pocket depth is automatically pulled from the model. The user then makes selections such as type of tool, climb or conventional machining to complete the program block for that feature. Because 3D Import can also automatically calculate transform planes, it can create programs to machine five sides of a part on a five-axis machine.

A window such as this enables users to input cutting parameters to complete each program block.

In addition, this feature can gather Z-axis depth information from 3D .dxf files, and it offers the capability to program directly from splines (curves that can be shaped in CAD by manipulating points) without traditional editing for missing geometry.

Related Content

-

Key CNC Concept No. 1—The Fundamentals Of Computer Numerical Control

Though the thrust of this presentation is to teach you CNC usage, it helps to understand why these sophisticated machines are so important. Here are but a few of the more important benefits offered by CNC equipment.

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

-

From Tradition to Transformation: Century-Old Manual Machine Shop Adds CNCs

After 122 years of working with manual mills and lathes, this fifth-generation shop acquired assets of a local CNC machining business and hired the owner. Here’s how it’s going a year later.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)