Float Your Air Plugs for Easy Part Alignment

One way to design clearance forgiveness into an air plug is to enable some float.

One of the topics we have often talked about with air gaging is the versatility of the air jet. Due to its small size, it is difficult to find a better way for making multiple-dimension diameter checks simultaneously in a bore. Whether the bore is the same diameter, has multiple diameter sizes or is tapered, there is a strong possibility that an air plug can be designed to handle multiple diameters at the same time with only one insertion. In a high-production manufacturing process, this is a great time saver.

For multiple-diameter plugs, it is critical to ensure that the concentricity of the various bores is consistent with the diameter clearances of the air plug. Because air gaging is a fixed-plug measuring system, there are very tight clearances between the body of the plug and the part. If there are multiple diameters to be measured, the bores must be concentric to the same level of tolerance as the centricity of the air plug. Otherwise, a problem may occur in which the plug will not fit into the multiple-diameter bore. It will jam and not be able to complete the measurement.

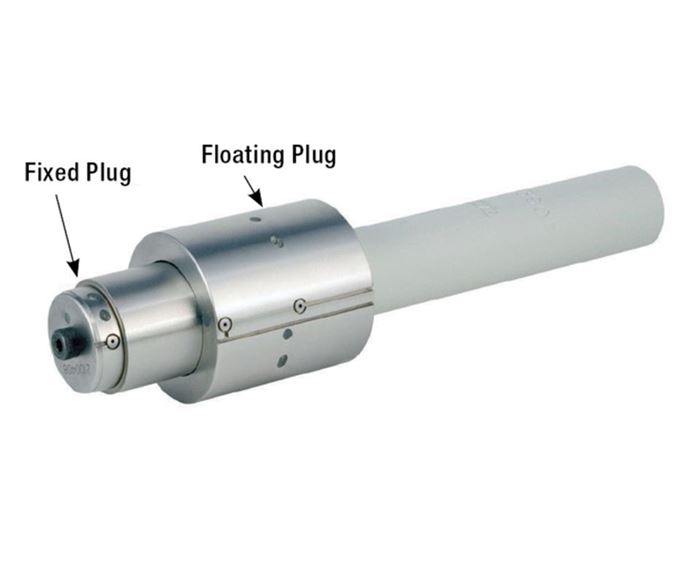

However, there are ways to design a little forgiveness into the air plug to enable some “float” (within two or more diameters) so that it can align to the bore and still have the clearance needed for good air gaging. In effect, this creates a two-part air plug. The plugs are connected in a single assembly, but one plug can float in all directions. The floating plug can align to the part once the front section is inserted into the first bore enabling the same air-plug performance and production without the hazard of jamming during insertion.

A similar application for multiple-diameter air gaging exists when a part consists of multiple, tight-tolerance bores that do not have the same level of relative bore location. Since the tight tolerances require measurement in a high production environment, a custom-fixture gage with multiple air plugs is needed.

In this case, the issue is that the location tolerance on the bores is apt to vary more than the plug clearances if the plugs were hard-mounted to a common fixture. This is a very common condition on multiple-bore parts in which the location is a lot looser than the bore diameter.

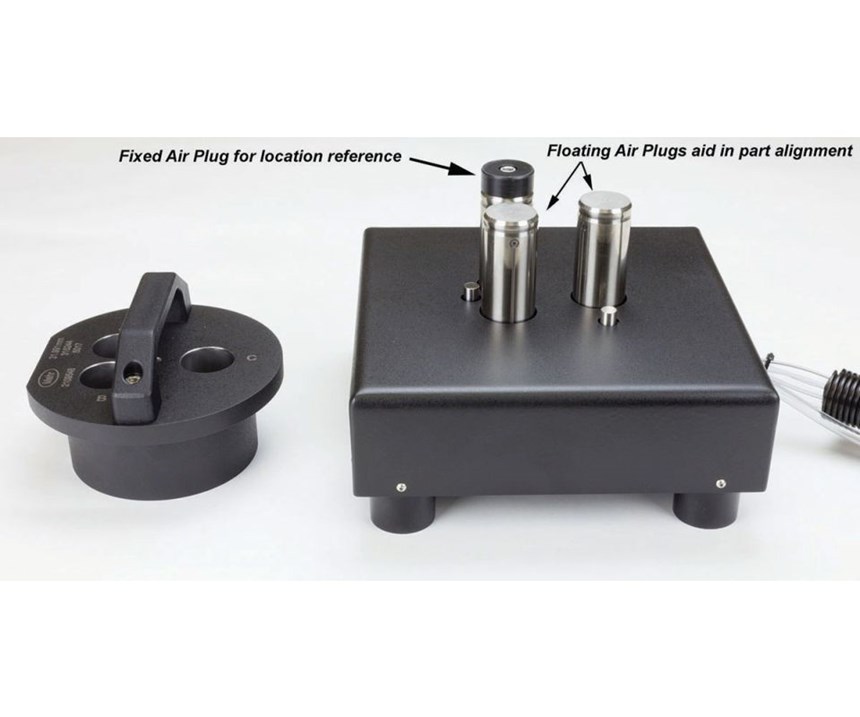

Again, there are design approaches that enable the air plugs to float in relationship to a fixed plug, thereby aiding the user when placing the part onto the air-gage fixture. Just as with the concentric bore, in this multiple-bore example, the concept is to make one plug fixed and let the other air plugs float and align themselves to the other bores. The float does not have to be much, but rather just enough to overcome the inherent errors in the part while enabling easy part placement by the user.

In fact, air again can aid in this design. Special air-compliance mounts act as a simple mechanism enabling the second or third plug to align to the fixed plug. In addition, when checking multiple bores, design features can make the insertion even easier. For example, the fixed or reference air plug is longer and features a special lead-in nosepiece. The operator must only be concerned about one plug to align. The second plug floats and is a little shorter to enable the user to easily find the second location. The third air plug is the shortest of the three with slightly more float to find the third bore without difficulty. This is very simple for the operator to use despite the high tolerance requirements on the bores.

When these floating features are used for multiple-bore air gaging applications, more capability is put into the user’s hands while at the same time making the measurements easy and fast.

Related Content

What Should Machinists Know About In-Machine Probing?

In-machine probing doesn’t reach the power of CMMs but can still be useful for pre- and mid-process control, as well as for “rough screening” of parts.

Read MoreChoosing the Correct Gage Type for Groove Inspection

Grooves play a critical functional role for seal rings and retainer rings, so good gaging practices are a must.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreDetermining Out-of-Roundness at the Point of Manufacture

George Schuetz, Mahr Inc.’s Director of Precision Gages, offers these techniques for measuring roundness on the shop floor.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)