Identifying and Overcoming Skill Vulnerabilities in Staffing

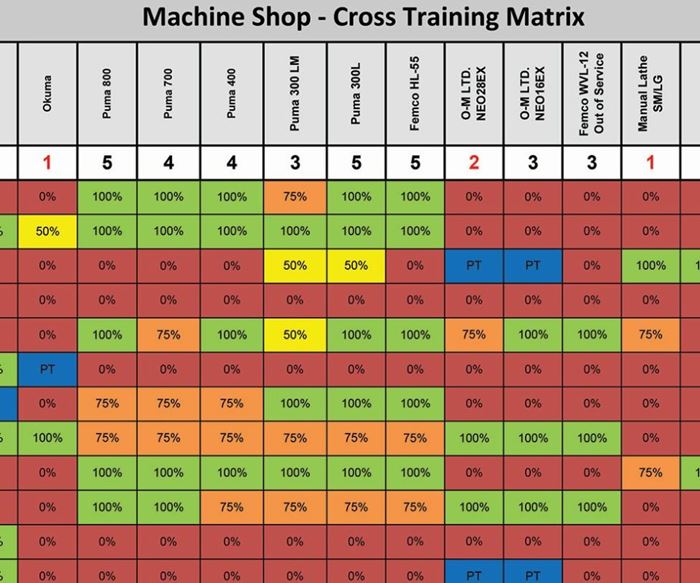

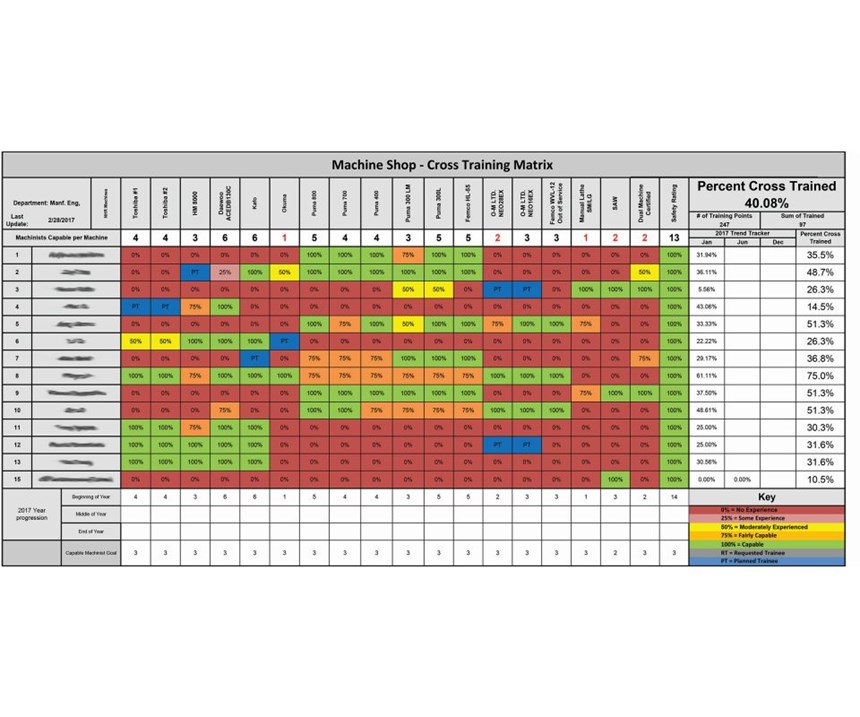

This shop tracks cross-training as a performance metric. Management sees how many employees are fully capable of running each different type of machine tool. The data have helped the shop improve in this area, particularly since employees see the very same data as well.

Reducing head count due to economic challenges is a response that often leads to longer-term challenges. This is particularly true in machining facilities, where skilled employees oversee sophisticated machines. If the facility is left with too few of the key people who are able to run the shop’s most complex equipment, then having just one or two of those critical employees resign or become sick could leave costly equipment sitting idle.

After a necessary downsize, a machining facility in Texas recently took stock of its own staffing to see how vulnerable it was to this danger. The resulting chart it created turned into a tool for improving staff members’ skills by advancing cross-training within the facility.

This company serves an industry segment in which both rapid expansion and downsizing are common: the oil and gas sector. Understandably, it wishes to remain unnamed (publicity for reducing headcount is something no company wants). The CNC machining capabilities involved in making its broad product line cover a range of machines—milling, turning and mill-turning—in an array of sizes and more than a half-dozen brands.

The manufacturing engineering manager for this facility notes that the variety of machine tools here had not posed a personnel challenge prior to a few years ago. In 2014, however, the company’s business crashed along with the oil market. He and other facility leaders had to oversee significant cuts, most notably staffing cuts. “And as soon as the layoffs were done,” he says, “the first question we asked was: Which skills did we lose?” He feared certain machine tools had too few people left on staff who were proficient in running them.

That fear proved valid. The facility’s strategy team took an inventory of all the machine proficiencies remaining in the staff. The team members created a chart with all the employees’ names down the vertical axis and all the machine tool types across the horizontal. Then, for every pairing of employee and machine, they rated ability. They defined the increments on a scale (0-, 25-, 50-, 75- or 100-percent proficient), and scored every employee’s proficiency on every machine.

They discovered they were in danger on many machines. That is, many machines had only one or two remaining staff members able to run them reliably. But in making a chart to realize this discovery, they also made an effective tool for addressing this problem.

These strategy team members openly shared their findings with employees. They began choosing employees to train on machines where the need was greatest. More significantly, they began inviting employees to increase their versatility in the shop by volunteering for their own cross-training. Employees are now able and encouraged to request the chance to be trained on any given machine, and the employee who has made the greatest advance in cross-training each year is honored at year’s end. The chart proved to be the beginning and the basis for a culture of continuous employee improvement.

Of course, in the beginning, it wasn’t easy, the manufacturing engineering manager says. “There was resistance,” he says. “We heard, ‘You can’t judge us that way.’” In fact, it still isn’t easy. Frequently, an employee’s score on a given machine is lowered. Proficiency of 100 percent means the ability to run the machine entirely unsupported and unsupervised, such as alone in the shop on a weekend. “But someone we’ve given that score might prove to have trouble machining a critical feature,” he says. “So we tell that person: When you’ve machined that same part X number of times without a non-conformance report, your score will go back up.”

He says eventually he hopes to see employee compensation linked to this cross-training, so employees are paid more if they know how to operate more machines. That connection to compensation does not exist today. However, employees seek their own diversification regardless. Just making the data visible has been enough to encourage that improvement.

Related Content

All-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreWill the “Great Resignation” Become an Opportunity for Manufacturers? Get Ready for the Returning 3 Million

The Great Resignation will become a Great Reapplication when employees currently able to stay out of the workforce return to it looking for something better. Machining employers that are already evaluating candidates for fit, without demanding specific skills coming in, might be positioned well to draw upon this wave.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)