Introducing GF Machining Solutions

Georg Fischer AG, the global industrial firm based in Switzerland, has a new name for the division that supplies well-known brands of electrical discharge machines, high speed milling, automation/tooling, spindles and more.

Georg Fischer AG is a global industrial firm based in Switzerland. Georg Fischer, however, is not a name that is widely recognized among manufacturing companies in the United States. In fact, it's the parent of the companies that produce manufacturing equipment under brand names such as AgieCharmilles (electrical discharge machines), Mikron (high-speed milling), System 3R (automation and tooling) and Step-Tec (milling spindles). Georg Fischer AG is also a major player in piping systems and automotive components—two areas in which it is well-known, especially in Europe.

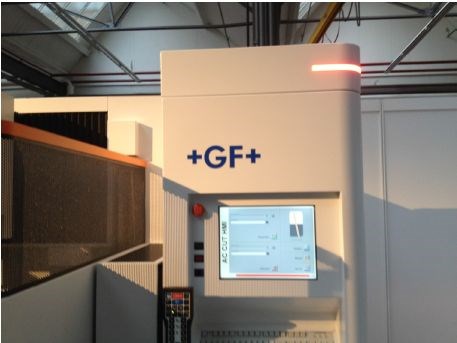

So even if the name isn't as strong as it could be in the U.S. and other regions of the Americas, the company is eager to promote its unified corporate identity without diminishing the value of its familiar brand names of manufacturing equipment. For this reason, Georg Fisher has given a new name to the division that offers these brands. As of January 1, 2014, the division is now known as GF Machining Solutions. A recent Webcast press conference with Glynn Fletcher, president of GF Machining Solutions Americas, revealed further details about the new name usage, logos and branding. For example, the corporate logo, +GF+, will appear on machine enclosures, nameplates and labels, along with the product-specific brand name such as AgieCharmilles for EDM and laser technology, Mikron for high speed milling, and so on. The Step-Tec and System 3R brand names will also still be used under the umbrella of the GF Machining Solutions portfolio, Fletcher explained.

“While EDM remains a vital part of our company, we have grown to offer a much more comprehensive portfolio of products and services. This change communicates to the market what our customers already know: that we offer world-class, comprehensive solutions for every aspect of their operations,” Fletcher said. In addition to the name change, Fletcher said a new design style will be implemented for the GF Machining Solutions website, sales literature, business cards and other external communications.

Related Content

-

Weiler to Debut New Automation Features For Its Lathes

Weiler’s V 110 four-way precision lathe introduces features new to the U.S.

-

Modern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

-

Niche Work If You Can Get It: A CNC Machine Shop Crafts Its Own Destiny

The latest innovations in metalworking aren’t always related to CNC automation or robotics. For Rosenberger North America, a 2022 Top Shops Honoree, it is the company’s niche processes that create the biggest successes.

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)