July 2019 Product Spotlight: Grinding

This month’s Modern Equipment Review Spotlight focuses on grinding and abrasive machines and equipment.

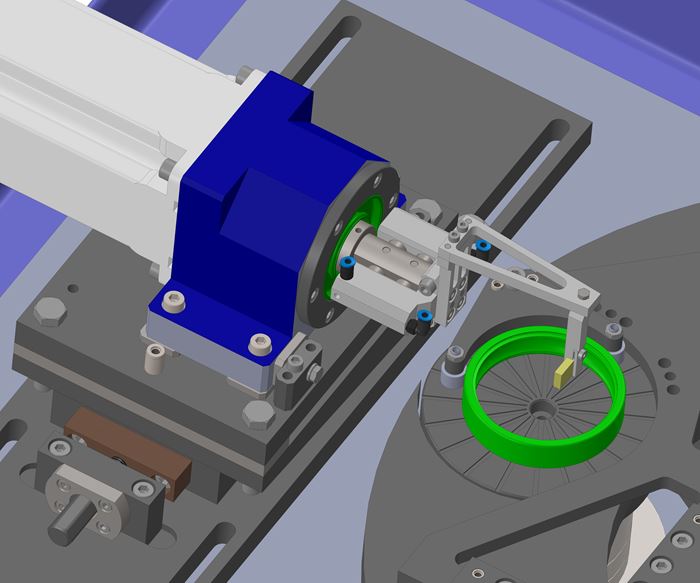

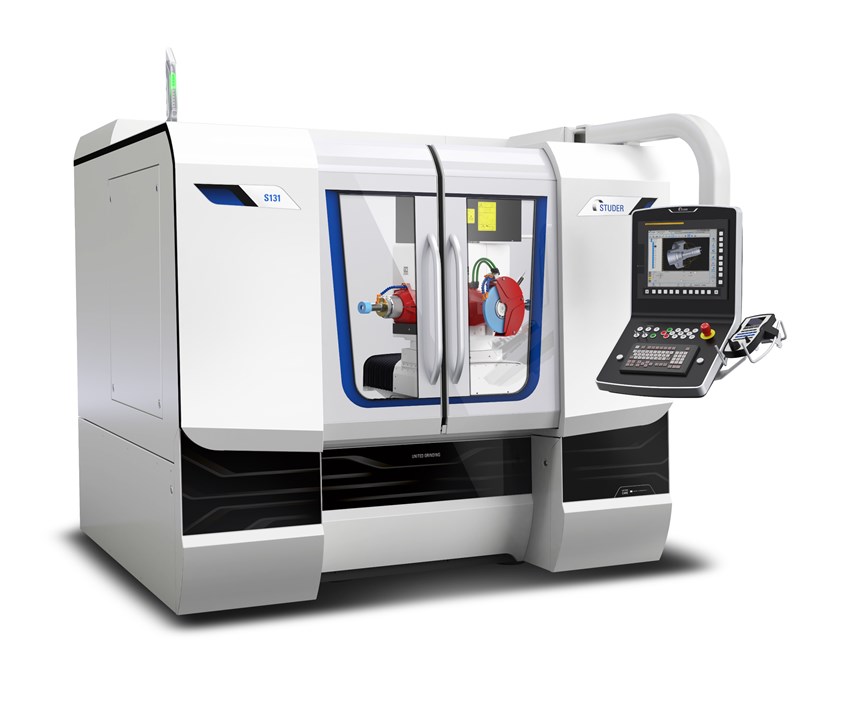

The image gallery above, based on Modern Machine Shop magazine’s Modern Equipment Review Spotlight, features a selection of the product releases we have recently published about grinding and abrasive equipment, ranging from heavy-duty superfinishing machines to cylindrical grinding machines to flap discs. More can be found in our Zone dedicated to grinding technology.

Swipe through the gallery for details about each product, and follow the caption links for more information. Products featured in this month’s spotlight come from the following companies:

- Nagel Precision

- Okamoto

- United Grinding (Studer)

- Weiler Abrasives

- Weldcote Metals

Related Content

-

Volumetric Accuracy Is Key to Machining James Webb Telescope

To meet the extreme tolerance of the telescope’s beryllium mirrors, the manufacturer had to rely on stable horizontal machining centers with a high degree of consistency volumetric accuracy.

-

A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

-

How to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAM system. Here’s how the company succeeded, despite the newness of it all.