Launching an Apprenticeship Program for $130

This shop uses an inexpensive plug-in for a website-hosting platform to manage its custom, in-house apprenticeship program.

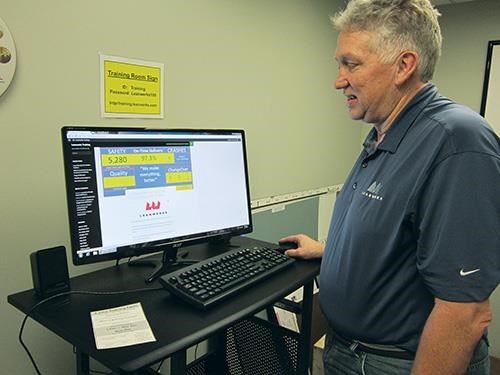

Paul Harbath, director of quality and continuous improvement for LeanWerks, has been key to helping develop the lessons for the shop’s Technical Excellence Training (TExT) program and administrating it.

LeanWerks calls it “TeXT.” TeXT stands for Technical Excellence Training program, an in-house apprenticeship program the shop developed to cultivate its own talent and provide new hires with a clear pathway leading to a machining career.

To manage it, the shop used WordPress to create a TExT “training website,” and then purchased a plug-in called LearnDash, which effectively turns WordPress into an online learning management system. The one-time cost for the LearnDash license was a mere $130.

As described in this article, many training lessons in the TeXT program include instructional video taken of actual LeanWerks shopfloor processes and practices to clearly outline the steps required to complete a given task safely and effectively. To date, the shop has produced more than 130 such videos for its TExT program. The article mentioned above includes an example of a training video LeanWerks produced explaining how to properly fill out first- and final-article inspection reports for a given job.

Related Content

-

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

-

All-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

-

8 Ways to Increase Productivity on the Manufacturing Floor

When it comes to machine shop productivity, continuous improvement depends on efficient employees, equipment and processes.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)