Look at Your Shop’s Progress Over the Long Term

The here and now is not always a good indicator of where you stand as a company and the positive changes you are making.

About a year ago, I found myself very frustrated because our shop was not doing well. You see, we had to throw away an entire run of parts because an insert chipped. Despite how many times I have said to check the tools before we leave for the night because it is cheaper to change the insert than to rick a bucket of bad parts, we had forgotten to change the insert. It failed soon after we closed the doors.

I walked back to our scrap barrels and found dozens of parts piled up. Additionally, we had an assembly project that had been lingering for months, and the customer was calling, telling us to deliver the unit. Ouch.

What was going on here? All of a sudden, it seemed like we couldn’t get out of our own way. Our scrap rates had spiked, deliveries were being missed, parts were being returned and our customers were complaining. Why couldn’t we seem to do even the basic things right? I was angry. First, we made bad parts that no one discovered, and then we shipped them out. To make matters worse, our new five-axis machining center, with a fancy robot and 35 pallet stations, was still sitting idle. We spent $1 million on a machine that was not running. Not only that, it hadn’t even been powered up since it was installed a year and a half ago.

At this point I was not happy. “Slow down, Tony,” I told myself. Maybe, just maybe, the problem was not in the shop, maybe it was me. Or, maybe it was the way I was looking at things. So, I decided to turn things around by not focusing on the negatives. Instead, I would look at the positives. I have always believed that it is important to look at the big picture even though it is easy to forget to practice what I preach. All the things I described above happened in a relatively short period of time. In order for me to see our situation with more clarity, I needed to look at things over for a longer period of time.

When I looked back at the situation a year later, I realized that we had significantly changed our customer base. We reduced our dependence on a major customer, and we worked to bring in customers from new industries. We developed our own parts washer and added it to our production line. We were continuing to work toward a change in ownership. We had employees step up and assume leadership roles when we lost our main programmer and engineer. Our workforce has been increasing, and we even hired a full-time Human Resources person to help fill the open positions as we continue to grow. What a difference a year can make.

During a recent conversation with Mike, the head of our lathe department, I asked, “Can you think back a year ago? Where were we, and what changes or improvements have we made since then?” He paused for a moment and reflected that we made two personnel changes within the lathe department during the past year. We also replaced one operator with another, which resulted in improved quality and reduced scrap. More recently, we added a young man who is “green,” but eager to learn.

Mike is feeling the effects of these changes. He has significantly more time for projects, such as adding a robot to a grinding operation and squeezing more productivity out of automated cells. Mike also reminded me that our workload has increased substantially. The lathes are busier, and they run for many more hours after we lock the doors and go home. This shows in our sales figures.

And what about that $1 million investment in the five-axis mill? Another year has passed, and we have a great job on the mill. It’s running 95 hours per week with minimal labor. In addition, we have a second job lined up that will consume another 40 hours. We are even beginning to talk about another machine.

Sometimes, it really is hard to see the forest through the trees. We all work hard; we all are busy. When you are in the heat of the battle, it is hard to see the day-to-day progress that you are making. Let’s remember to look at things over a longer period of time. Think back one month, six months, one year or even more. Where were you then, what were your struggles and where are you today? Chances are you are much further ahead. By looking back over a longer period of time, I realized that things were not really that bad. Maybe they were actually pretty good. So, take a minute, reflect and give yourself some credit. When you are finished looking back, turn toward the future. Where could you be next year?

Read Next

"Good Progress" But No Breakthrough in NAFTA Talks

Trade officials say they continue to make “good progress” this week on a revised NAFTA pact, even though a breakthrough doesn’t appear imminent.

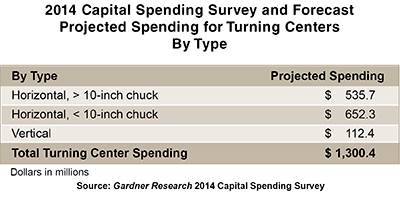

Read More$1.3 Billion Market Projected for Turning Centers, Metalcutting Job Shops Largest Spender

Horizontal turning centers with <10-inch chuck is the largest segment of the market at $652.3 million in spending projected. The table represents spending intentions for turning centers by type.

Read More3D Printing Workshop Has Successful Launch at NPE2018

Speakers at the inaugural 3D Printing Workshop emphasized mold tooling and end-use production, among other 3D printing applications.

Read More

.png;maxWidth=300;quality=90)