Machining, Manufacturing Technology on Display in Pfronten

Automation, additive manufacturing, five-axis machining and more was on display at DMG MORI’s recent open house at its Pfronten, Germany, campus.

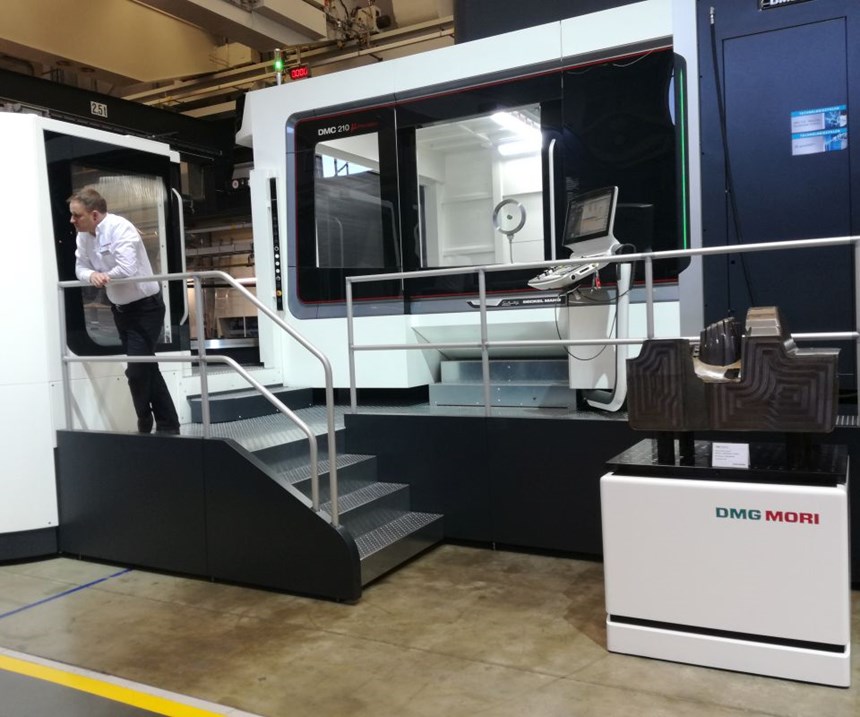

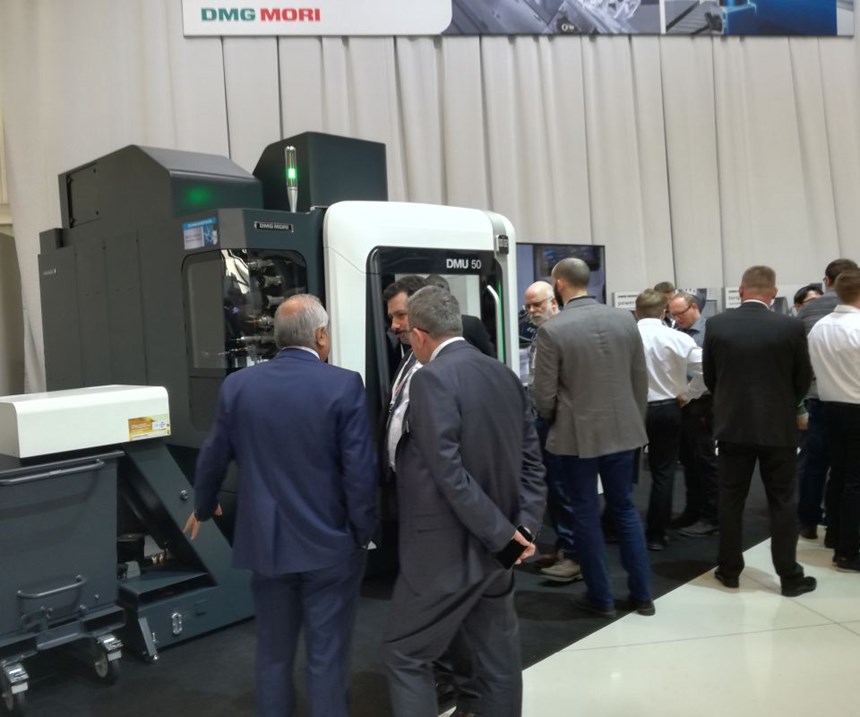

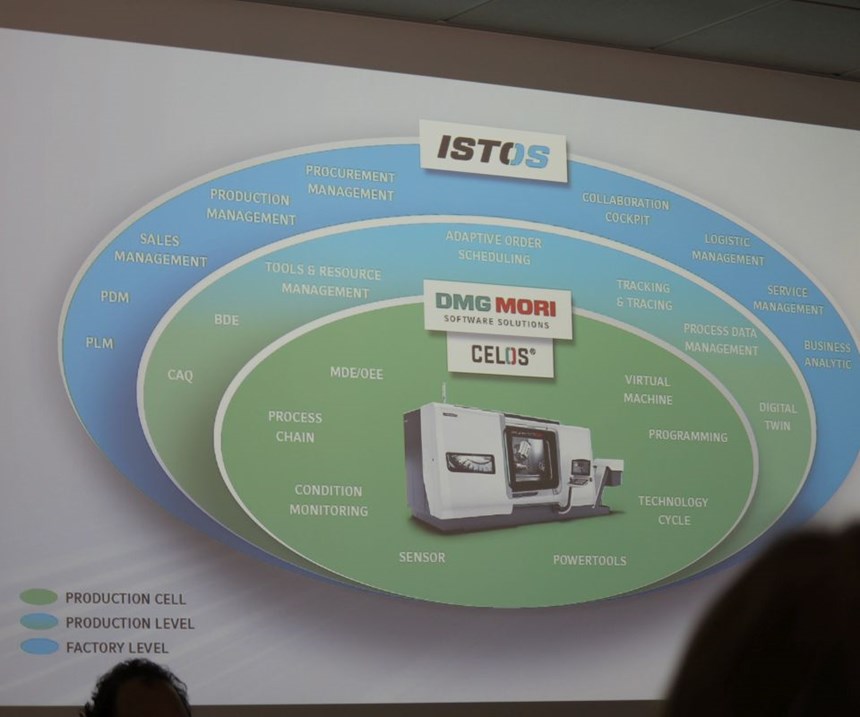

After Japan-based DMG Mori Co. acquired further shares in the German DMG Mori AG and reached a total shareholding of 76 percent in AG last year, the company’s president, Dr. Masahiko Mori, and DMG MORI’s CEO, Christian Thönes, seem to deliver on their promise to become leaner and focus on product quality and service. While DMG MORI once again underlined its technology innovation at the company’s recent open house at Deckel Maho in Pfronten, Germany, there were “only” three world premieres on display among the 80 machines showcasing the company’s range of product offerings, clearly a sign of the company’s consolidation efforts, including a reduced number of machines introduced to the market each year as well as the reduction of product offerings from 300 to 150.

With consolidating the product lines, the company has also closed its Dixi plant in Le Locle, Switzerland, plant in Chiba and the factory in Shanghai, and is now operating 14 plants worldwide, Dr. Mori said at the open house press conference. The former Swiss-made Dixi machines will now be available as DMG MORI machines called µPrecision, which are available for DuoBlock, Portal and NHX 8000 machines. While the machines will be assembled in Pfronten, the skilled employees performing the 500-hour scraping process for the guideways to ensure an accuracy of less than 15 µm will remain in Switzerland, a DMG MORI representative told me during the event.

The company also displayed a mobile automation system for lathes with intuitive programming via Celos Powertool. The core of the integrated turning cell is the new loading and unloading system Robo2Go, designed for mobile use. DMG MORI USA CEO Dr. Thorsten Schmidt added that he believes that around one-third of all machines delivered to U.S. customers are meanwhile automated, and the number of companies requiring automation or at least demanding automation options for future capacity expansion was growing, he said.

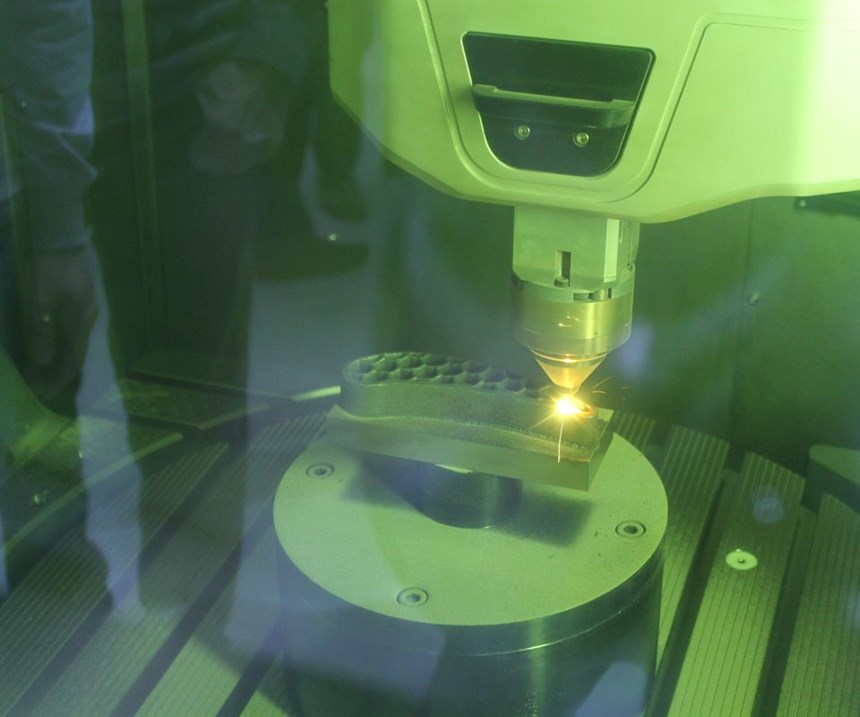

The slideshow above highlights a few technologies on display at the event, including additive manufacturing, laser texturing and five-axis machining. Approximately 200 U.S. customers came to the company’s annual open house, which clearly signals a positive mood among American manufacturers, Dr. Schmidt said. He is also happy to see a general sense of relief in the oil and gas sector, where recovery is already gaining momentum.

Related Content

-

4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

-

Partial Automation Inspires Full Cobot Overhaul

Targeting two-to-four hours of nightly automation enables high-mix manufacturer Wagner Machine to radically boost its productivity past a single shift.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

.png;maxWidth=300;quality=90)