Machining Technology Spotted at Amerimold 2018

Amerimold presents a range of mold production equipment, strategies and best practices. Here is some of the mold machining technology displayed at this year’s event, ranging from automation to CAD/CAM.

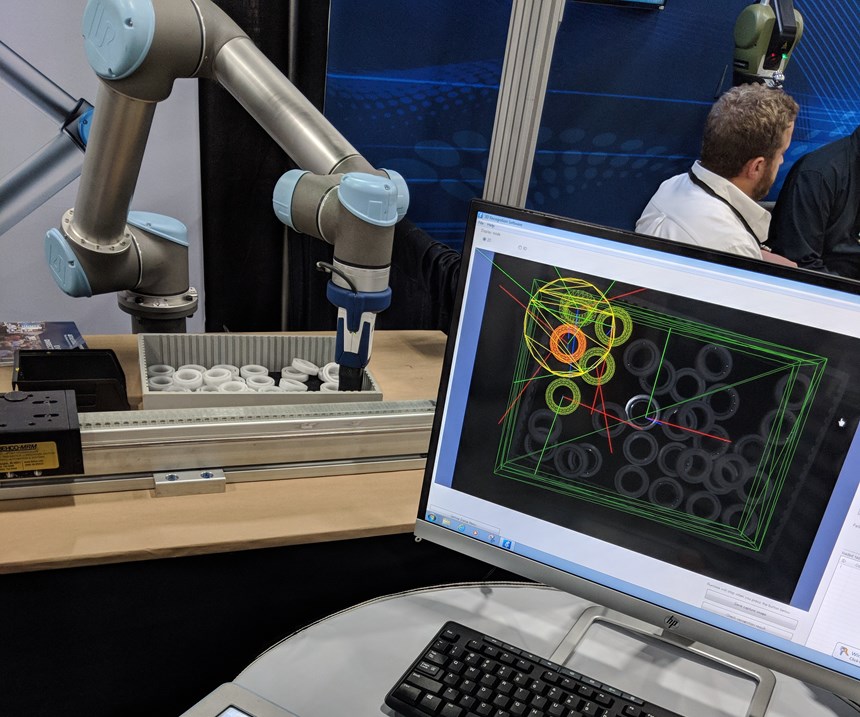

Amerimold 2018 featured a range of technology from nearly all aspects of the injection mold manufacturing process, with some exhibitors showcasing these capabilities with live demonstrations.

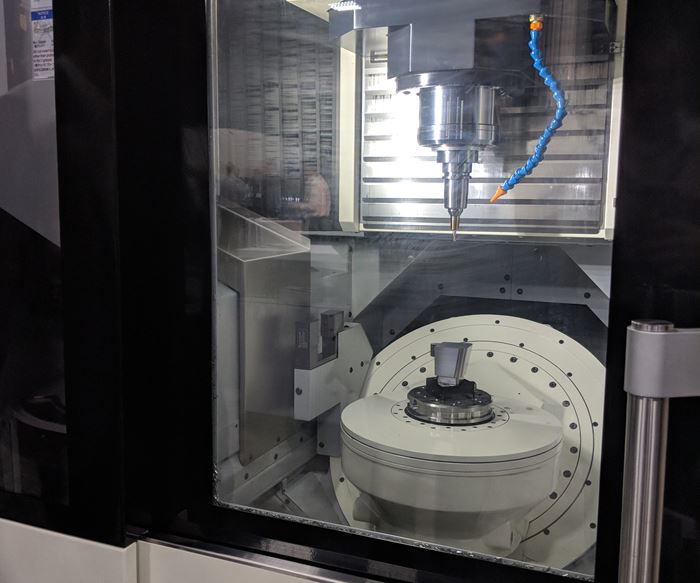

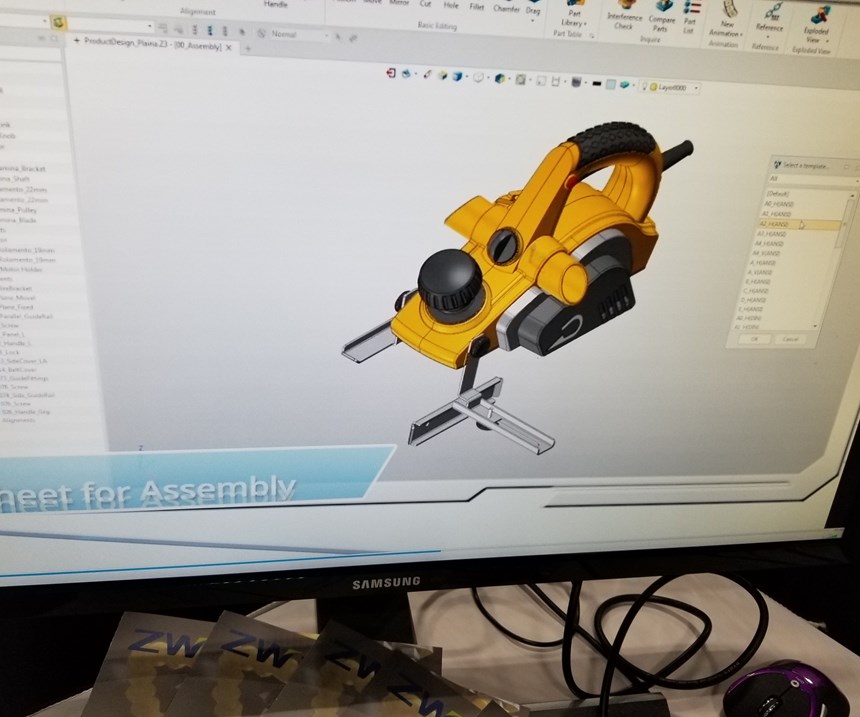

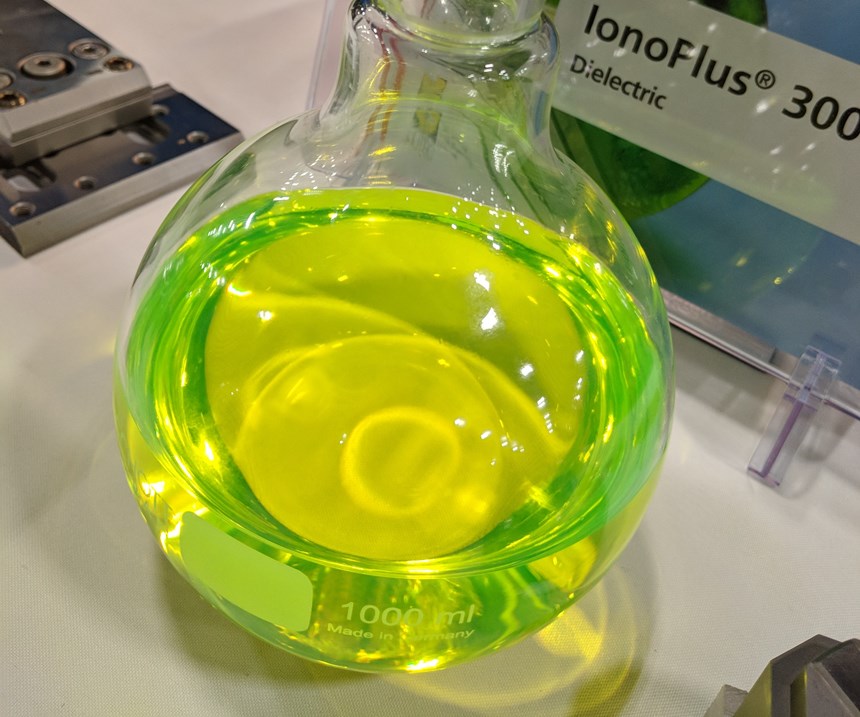

Mold machining products on display included CAD/CAM software for mold design and machine tool programming, five-axis machine tools designed to improve accuracy, tool presetters that can save save time by determining tool offsets offline, cutting tools to enable higher metal removal rates, collaborative robots to automate production tasks, workholding designed to provide machine tools with unobstructed access to workpieces, and EDM equipment that can deliver quality surface finishes. Scroll through the photos and captions above for highlights from the show.

Related Content

-

View From My Shop Video 1: A Deep Dive Into Automation with Advance CNC

Advance CNC leverages multiple forms of automation to increase its milling machines' productivity. Learn more in this episode of The View From My Shop.

-

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

-

Zero-Adjustment Bar Pullers Simplify Turning Automation

Spring-loaded grippers and adjustable programming are enabling bar pullers to fulfill their promise to save time and money in CNC turning automation.

.png;maxWidth=300;quality=90)