Measurement Technology Transcends Limitations

One metrology equipment supplier says its laser systems address common difficulties with noncontact measurement, while another touts a product that enables measuring surface finish on CMMs.

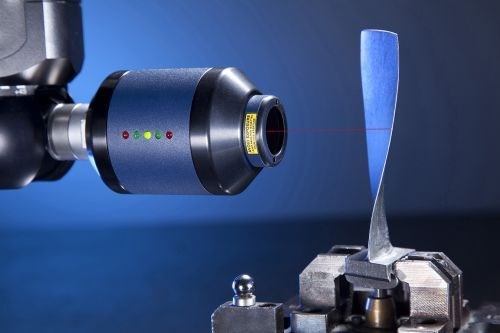

Inspection of aerospace jet engine blades as well as industrial turbine, marine and compressor blades is among the most suitable applications for Nextec’s laser measurement systems.

Two recent MMS articles covering metrology advances should be of particular interest to manufacturers serving the automotive and aerospace industries. First, Renishaw has developed a new probe option for its Revo five-axis measuring head that enables users to measure surface finish on CMMs rather than with hand gages or dedicated machinery. The second article describes how Nextec Laser Metrology's laser systems use a different approach to beam triangulation and an adaptive control to provide a faster alternative to touch probes for parts with minute, sculpted features, shiny surfaces, and other features that often pose problems for non-contact systems.

Related Content

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

-

4 Ways to Establish Machine Accuracy

Understanding all the things that contribute to a machine’s full potential accuracy will inform what to prioritize when fine-tuning the machine.

-

How to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)