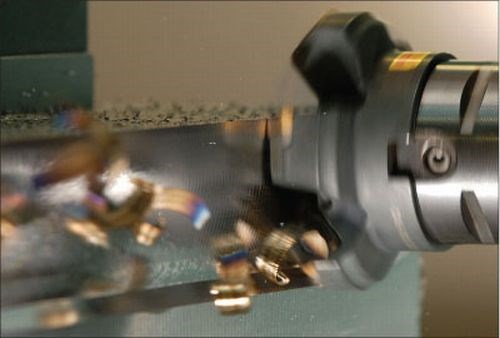

Milling HRSAs: The Checklist

When milling super alloys, there are certain process requirements that must be observed.

The article is part of the Milling Aerospace Alloys area of Sandvik’s new online knowledge center devoted to Titanium & HRSA Machining. If you are struggling to obtain more productivity in any of these high-temperature aerospace metals, take a moment to click through the resources that Sandvik Coromant has gathered together here.

Related Content

-

All-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

-

Twin Spindle Design Doubles Production of Small Parts

After experiencing process stalls in the finishing stage of production, Bryan Machine Service designed an air-powered twin spindle and indexable rotating base to effectively double its production of small parts.

-

How to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)